Transducer of the vibration type

A technology of instrument transformers and vibrators, applied in instruments, mass flow measuring devices, measuring devices, etc., can solve the problems of low natural frequency, increased installation costs, and growth, and achieve the effect of good balance and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

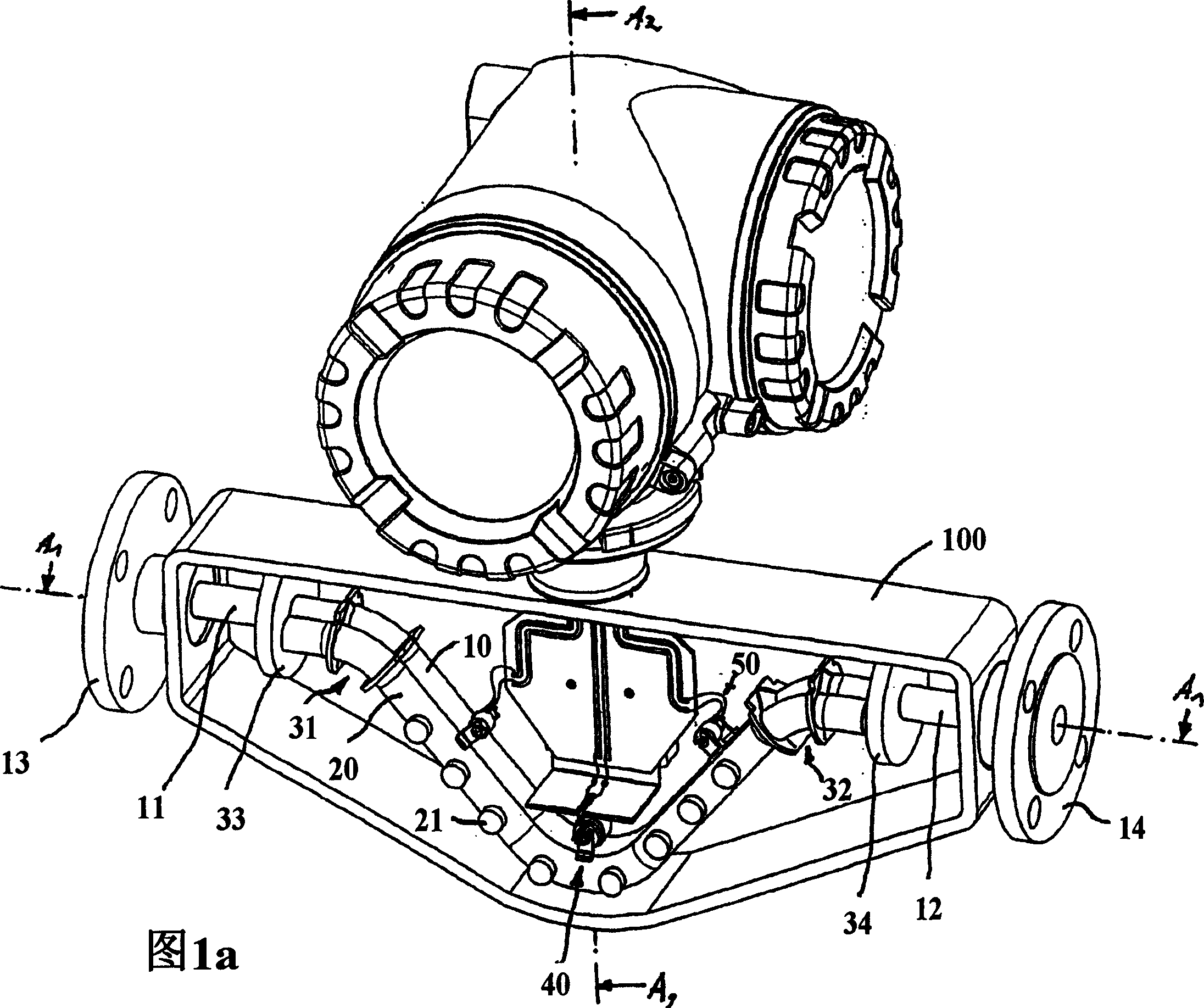

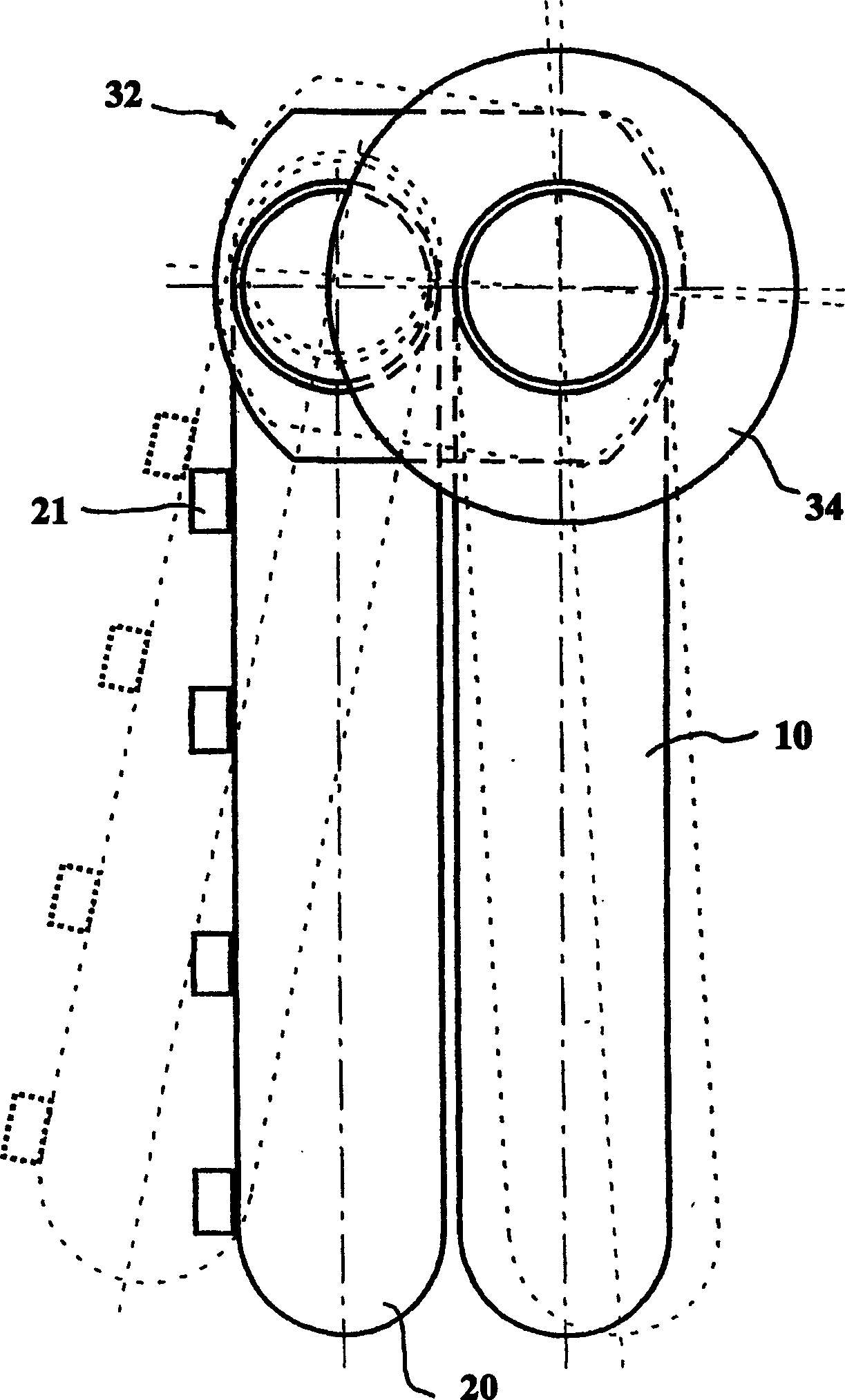

[0061] Figures 1a, 1b show a schematic view of a flow fluid measuring device with a vibrating instrument transformer. The function of an instrument transformer is to generate mechanical reaction forces in the flowing fluid, such as flow-dependent Coriolis forces, density-dependent inertial forces and / or viscosity-dependent friction forces, which are measurable, especially is measurably reacted to the instrument transformer by the sensor. Derived from these reaction forces, for example the flow rate m, the density ρ and / or the viscosity η of the fluid can be measured in a manner known to those skilled in the art.

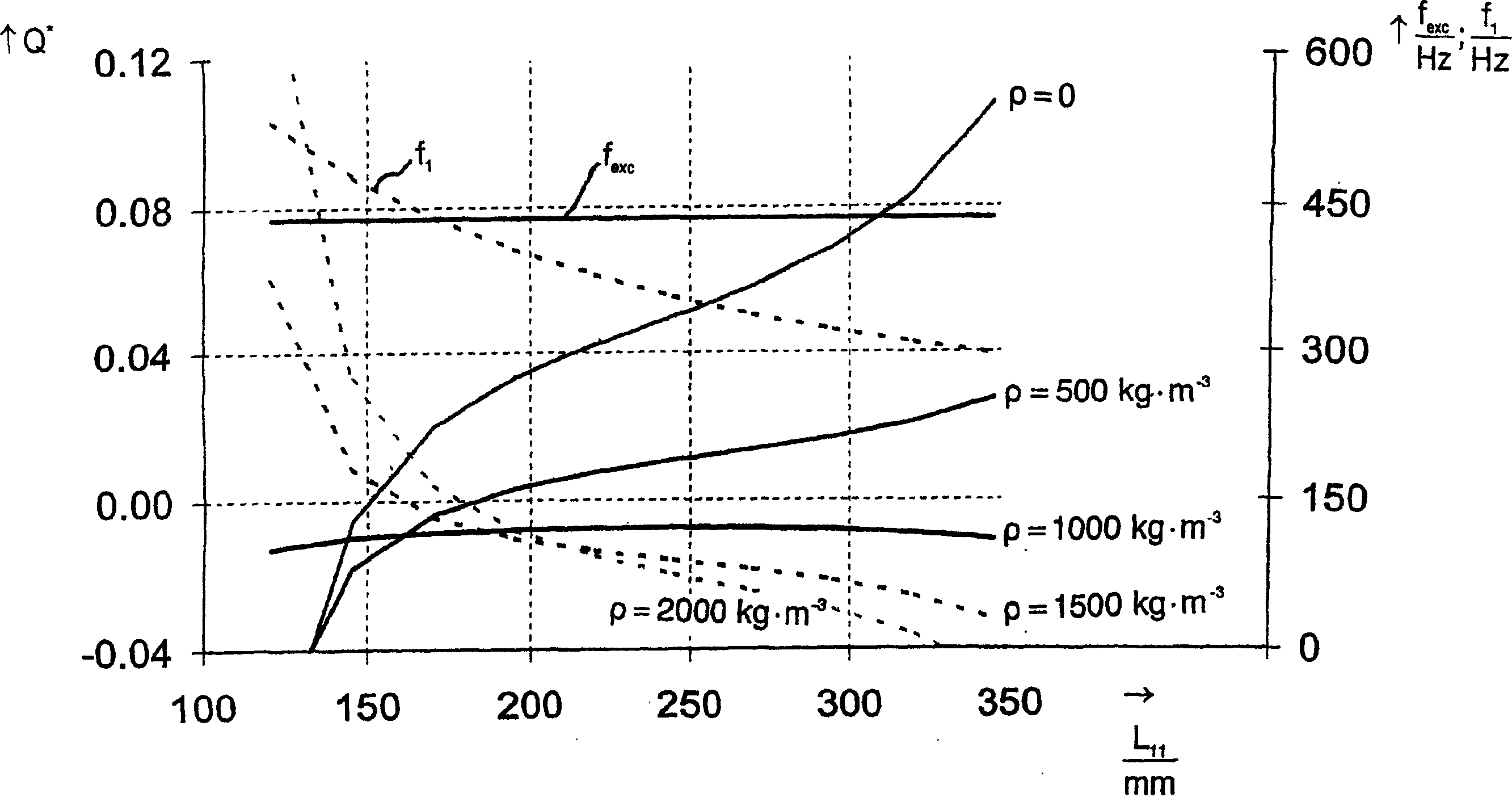

[0062] To conduct the fluid to be measured, the instrument transformer comprises a, in particular a single, curved measuring tube 10, which is connected via an inlet pipe 11 on the inlet side and via an outlet pipe 12 on the outlet side (not shown here) on the pipeline for conveying or discharging fluid. Measuring pipe 10, inlet and outlet pipes 11, 12 to each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com