Packing pot of aerosol and its production

A production method and technology for packaging cans, which are used in liquid distribution, other household appliances, household appliances, etc., can solve the problems of low product quality, damage to the interests of manufacturers and consumers, and insufficient aesthetics, so as to increase the added value of production and induce correctness. The effect of consumption and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

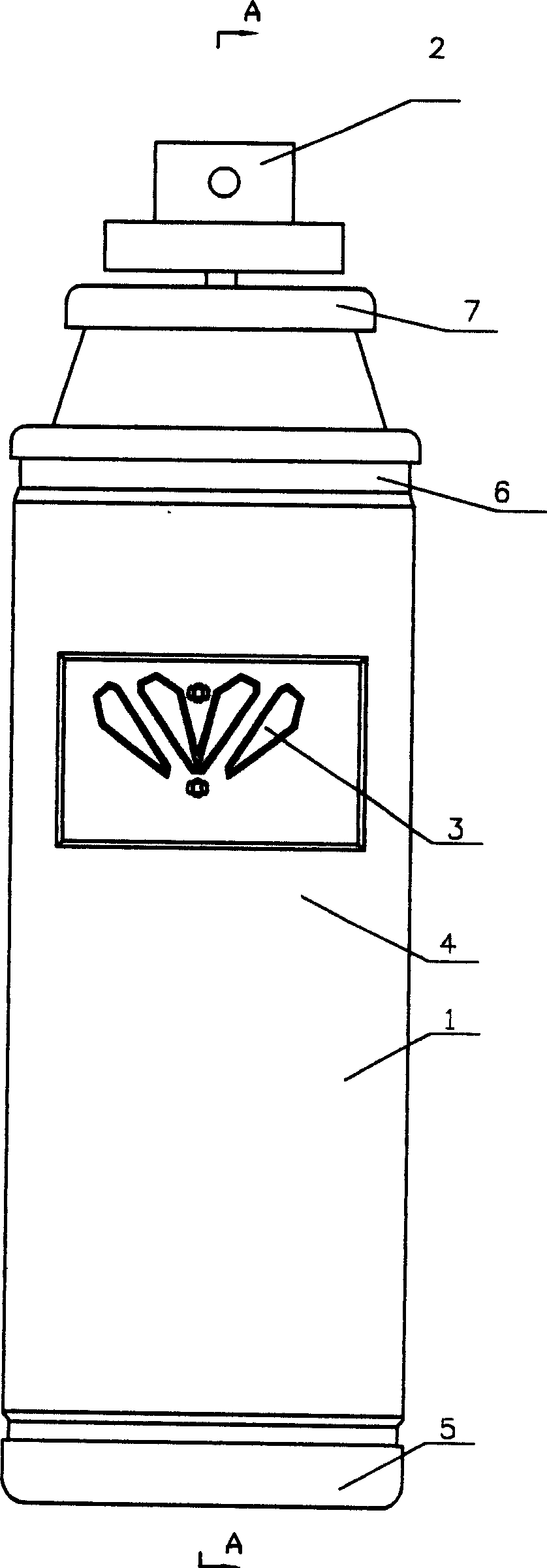

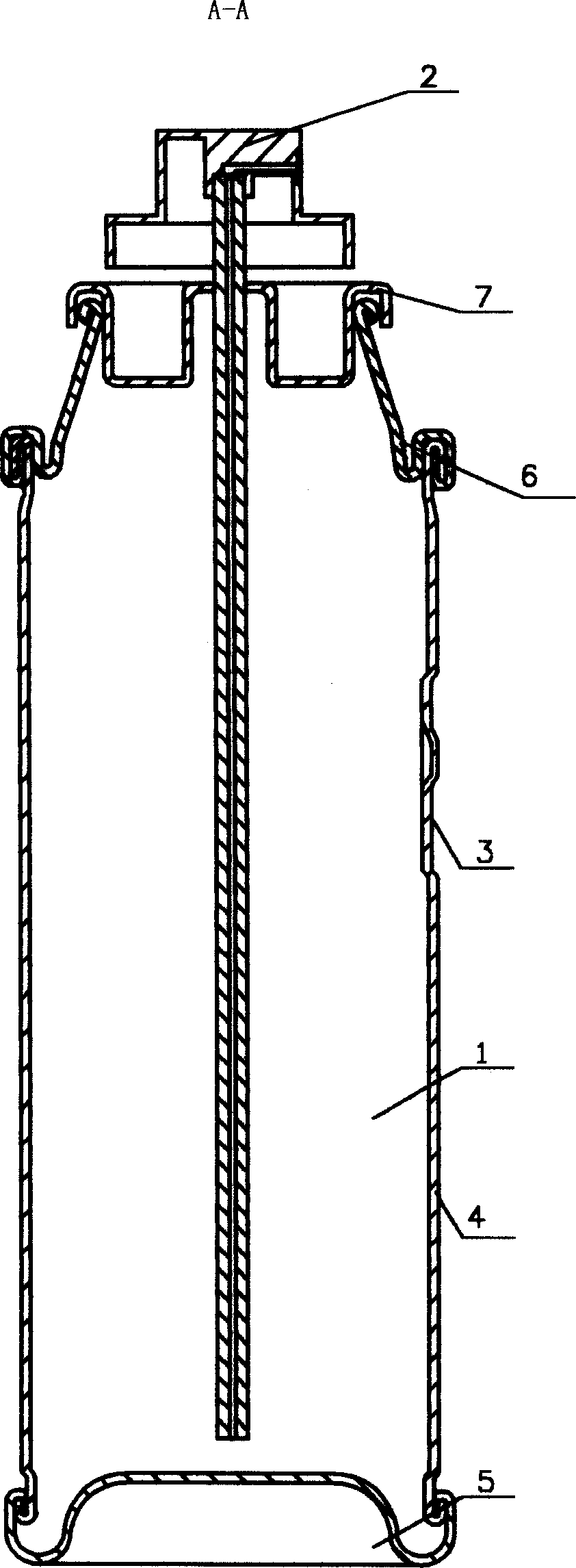

[0022] Such as figure 1 As shown in , an aerosol packaging can includes a can body 1, and a concave and convex relief pattern 3 is embossed on the cylindrical curved surface of the can body 1. The tank body 1 is composed of a tank barrel 4, a tank bottom 5 and a tank shoulder 6. The tank 4 is a cylindrical curved surface on which an uneven relief pattern 3 is embossed. The lower part of the tank barrel 4 is wound to the tank bottom 5, the upper part of the tank barrel 4 is wound to the tank shoulder 6, and the top of the tank shoulder 6 is the tank mouth 7, and the aerosol nozzle 2 is inserted into the tank mouth 7 for sealing and fastening.

[0023] The metal tank body 1 can be made of tin plate material.

[0024] Such as figure 2 As shown, a flat tinplate plate is coiled to form a cylindrical curved surface, and the cylindrical curved sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com