Loom with cooling system

A cooling system and loom technology, applied in textile, jacquard, textile and papermaking, etc., can solve problems such as high price, changing the normal and benign operation of looms, and increasing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

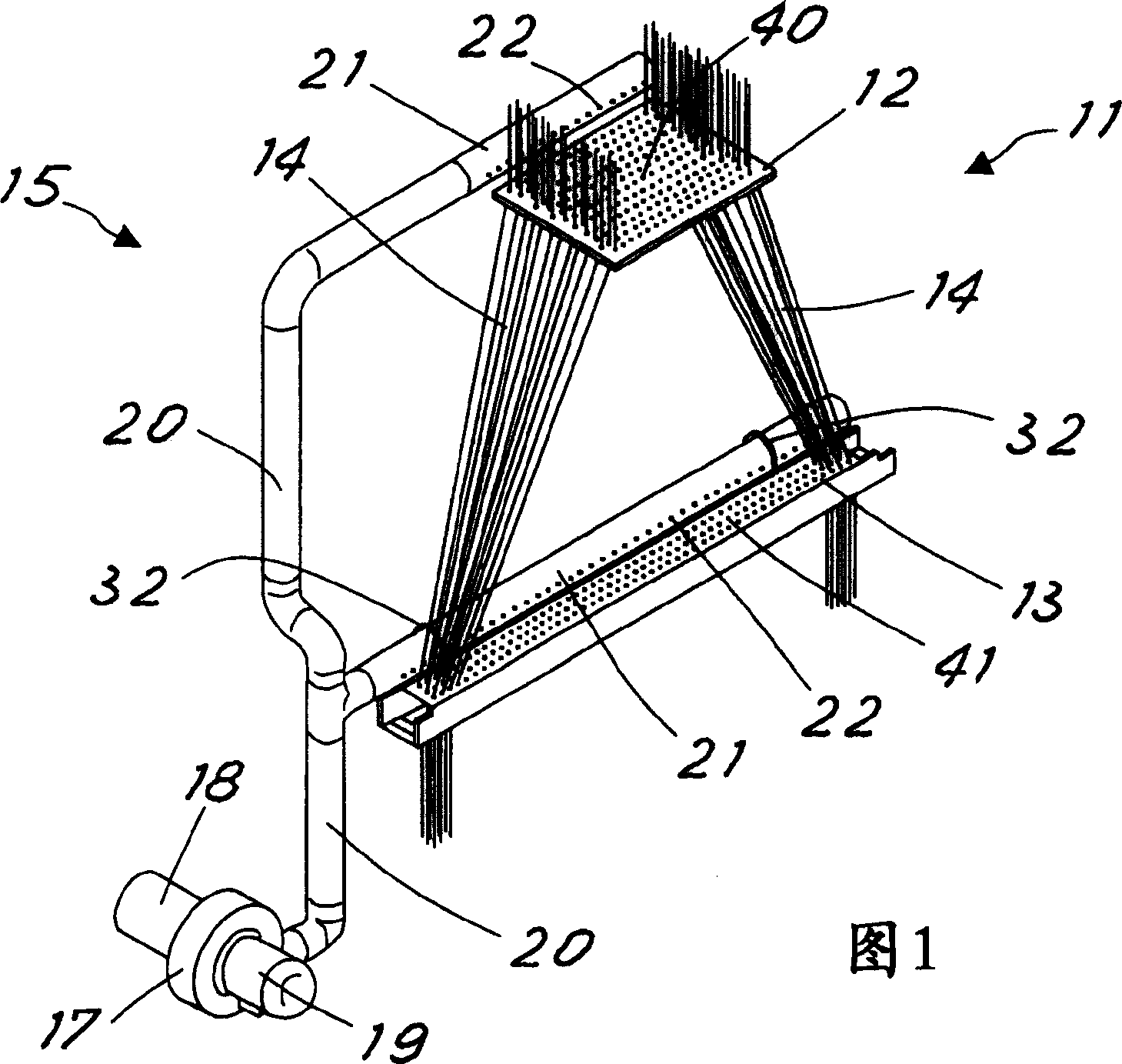

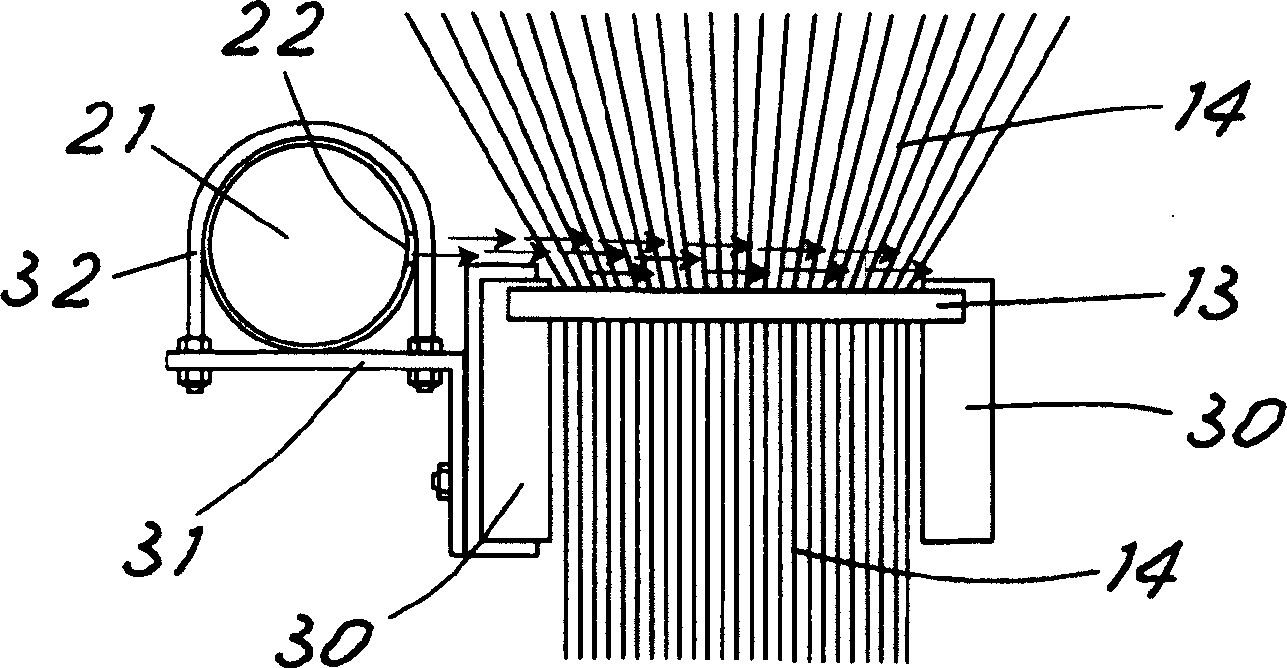

[0015] Referring to the drawings, Figure 1 shows an arrangement 11 of a Jacquard loom which is well known and therefore not shown or disclosed in detail. According to what is already known in the field of weaving, the device 11 comprises a threading plate 13 and a loom bed 12 for guiding the harness or suspension wire 14 in the device. According to the prior art, the guide plates 12, 13 are provided with a plurality of guide holes 40, 41, which are suitable for guiding the suspension wire 14 of the loom. The figures also show a cooling system 15 mounted on the frame for maintaining the guide plates 12, 13 and the suspension wires 14 adjacent to the guide plates at a sufficient low temperature. The cooling system 15 comprises a blower fan 17 (eg of the tangential type) driven by an electric motor 19 . Advantageously, said fan 17 is provided with an inlet filter 18 to clean said cooling air to be blown onto said suspension wire 14 and said guide plates 12 , 13 . At the outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com