Method for processing and removing electronic waste with a view to recovering the components included in such waste

A technology for electronic waste, waste, applied in the field of goods, which can solve problems such as environmental and health disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

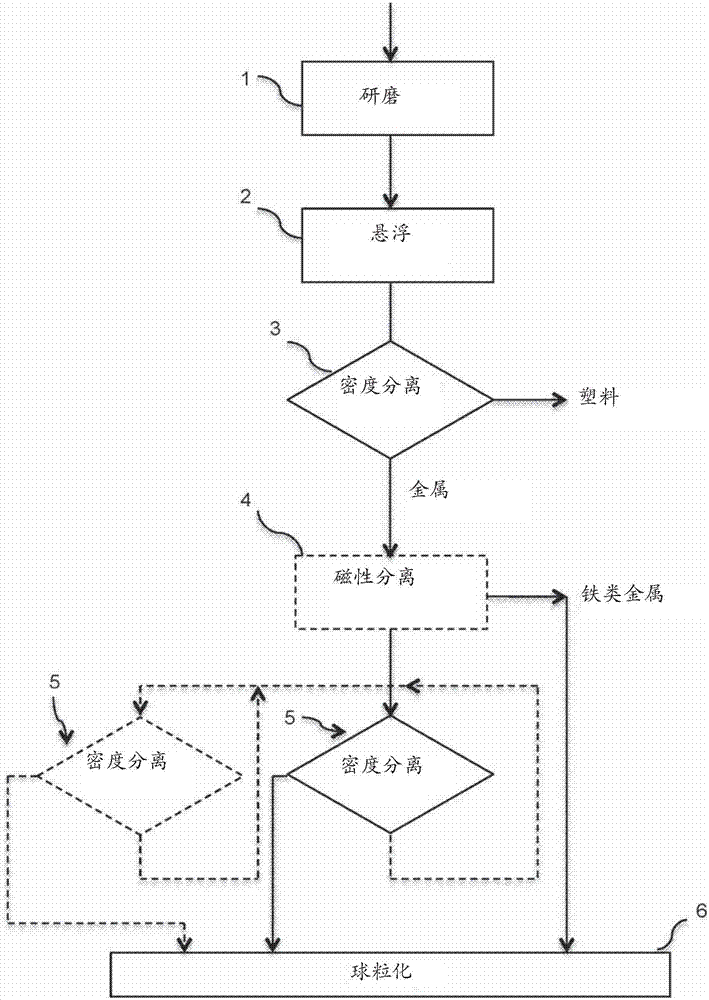

[0051] The steps of the process of the present invention and the means for performing these steps will be described below with reference to the accompanying drawings.

[0052] The process includes the following steps:

[0053] step 1 : Micronized

[0054] This step consists in grinding electronic waste (whole circuit boards, smart cards, etc.) until a particle powder is obtained with an average size preferably between 10 μm and 100 μm, and more preferably between about 20 μm and 50 μm. Depending on the nature of the waste and its intended composition, this grinding may be performed in one or more steps, optionally with regrinding of overly coarse particles produced by downstream particle size screening operations.

[0055] Here the target particle size is that of the metal, and grinding can result in coarser sized non-metallic particles (especially more ductile plastics) without compromising the effectiveness of the process.

[0056] Advantageously, the grinding is performe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com