Packaging structure of light sensing ship and its method

A technology of packaging structure and packaging method, which can be applied to electrical components, electric solid-state devices, circuits, etc., and can solve problems such as affecting the optical sensing effect and increasing the cost of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

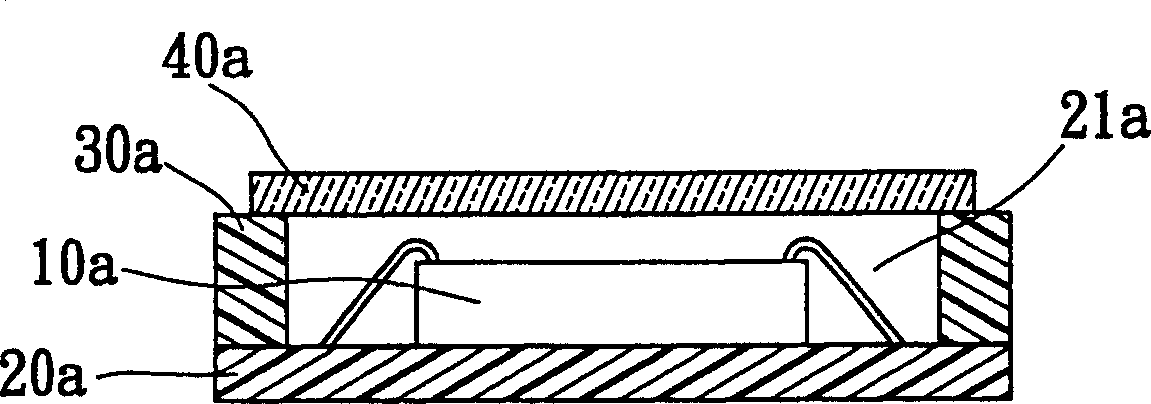

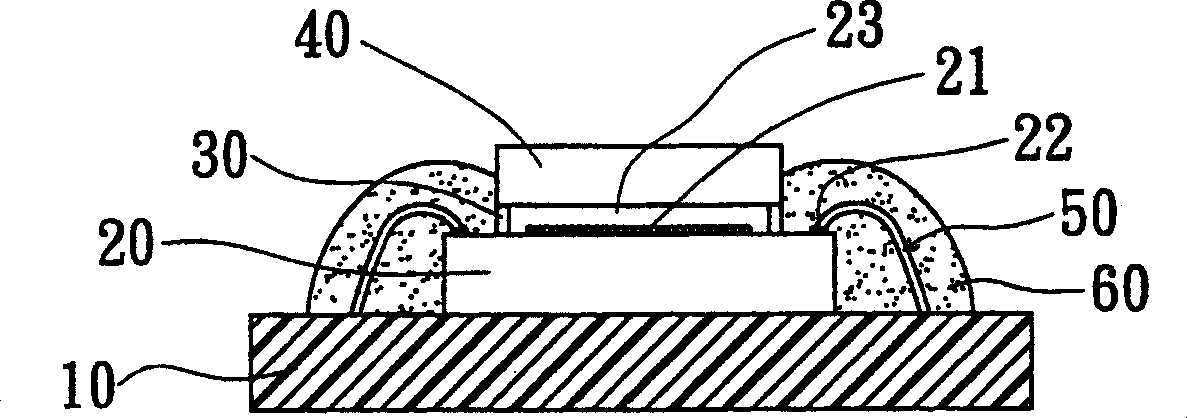

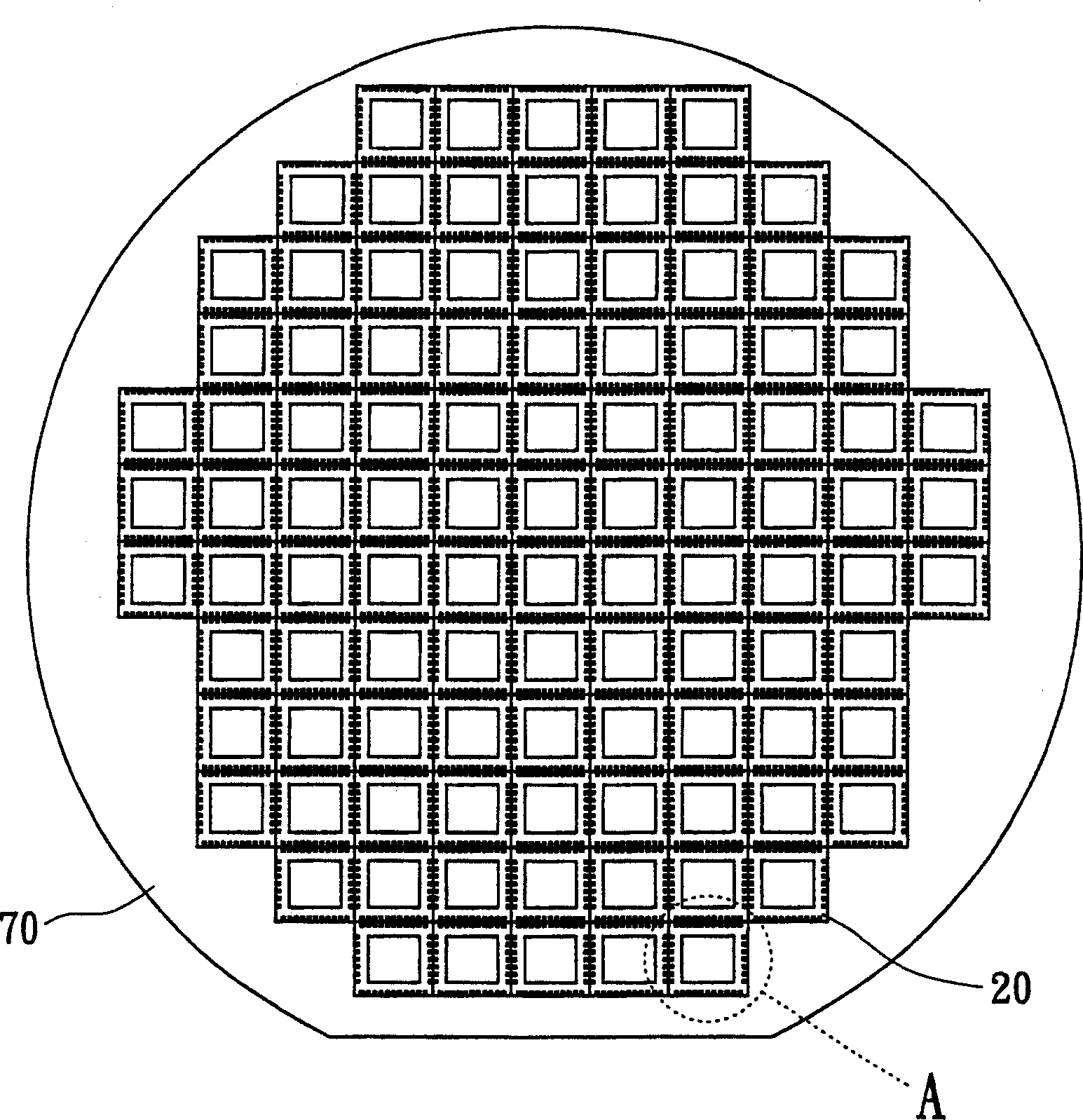

[0040] see figure 2 As shown, the present invention is a package structure of a photo-sensing chip, which includes a substrate 10, a photo-sensing chip 20, a support portion 30, a transparent plate 40 and a wire 50, wherein the photo-sensing chip 20 has a photo-sensing area 21 and welding pads 22 are arranged on its upper surface and the welding pads 22 are arranged around the light sensing region 21, and the light sensing chip 20 is arranged on the substrate 10, which can be a printed circuit board, The supporting portion 30 is set around the outer peripheral edge of the light sensing area 21 on the light sensing chip 20, and the transparent plate 40, such as a glass plate or a transparent resin plate, is fixed on the supporting portion 30 to correspond to the light sensing area. Measuring area 21, wherein a space 23 is formed between the transparent plate 40, the support portion 30 and the light sensing area 21 of the light sensing chip 20, and then the wire 50 is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com