Damper for washing machine

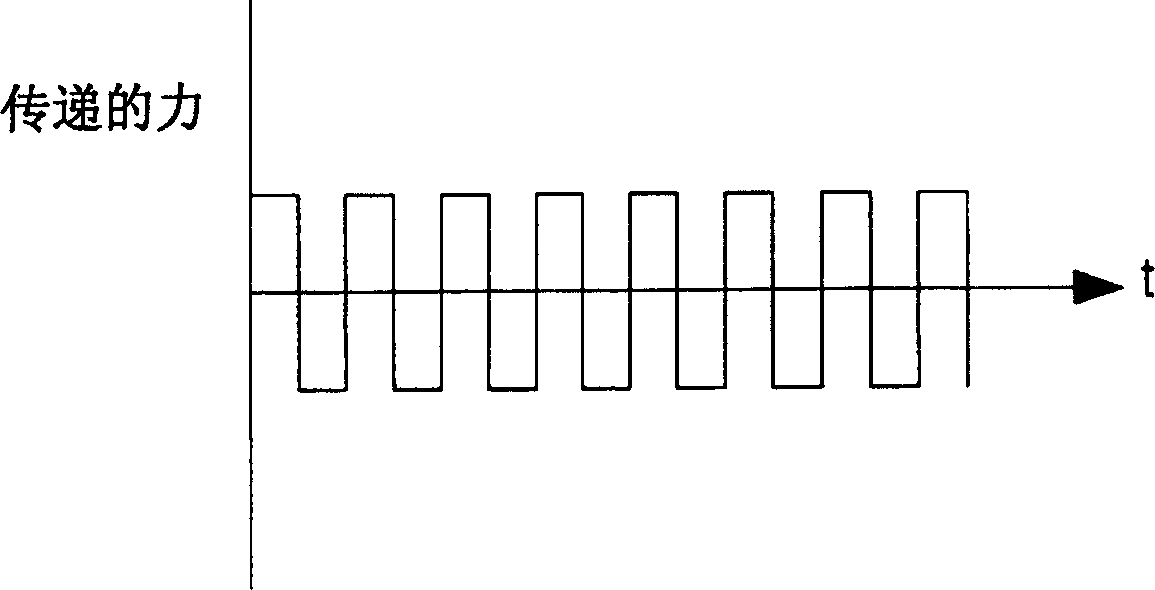

A technology of damper and washing machine, applied to other washing machines, washing devices, frictional shock absorbers, etc., can solve the problems that the vibration of the washing tub 6 cannot be effectively weakened, so as to prevent damage to corresponding components, prevent the periodic generation and weakening of noise The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

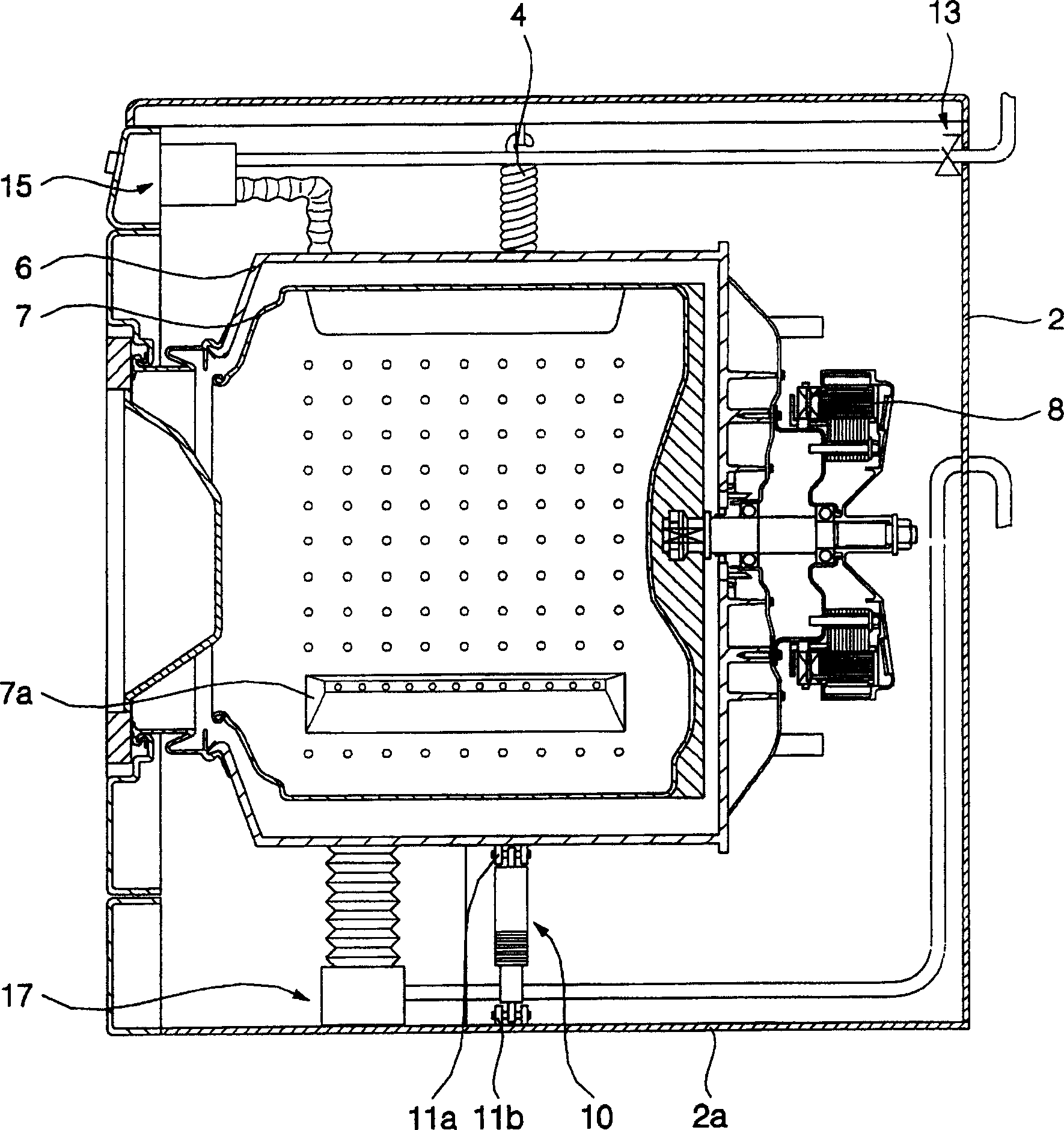

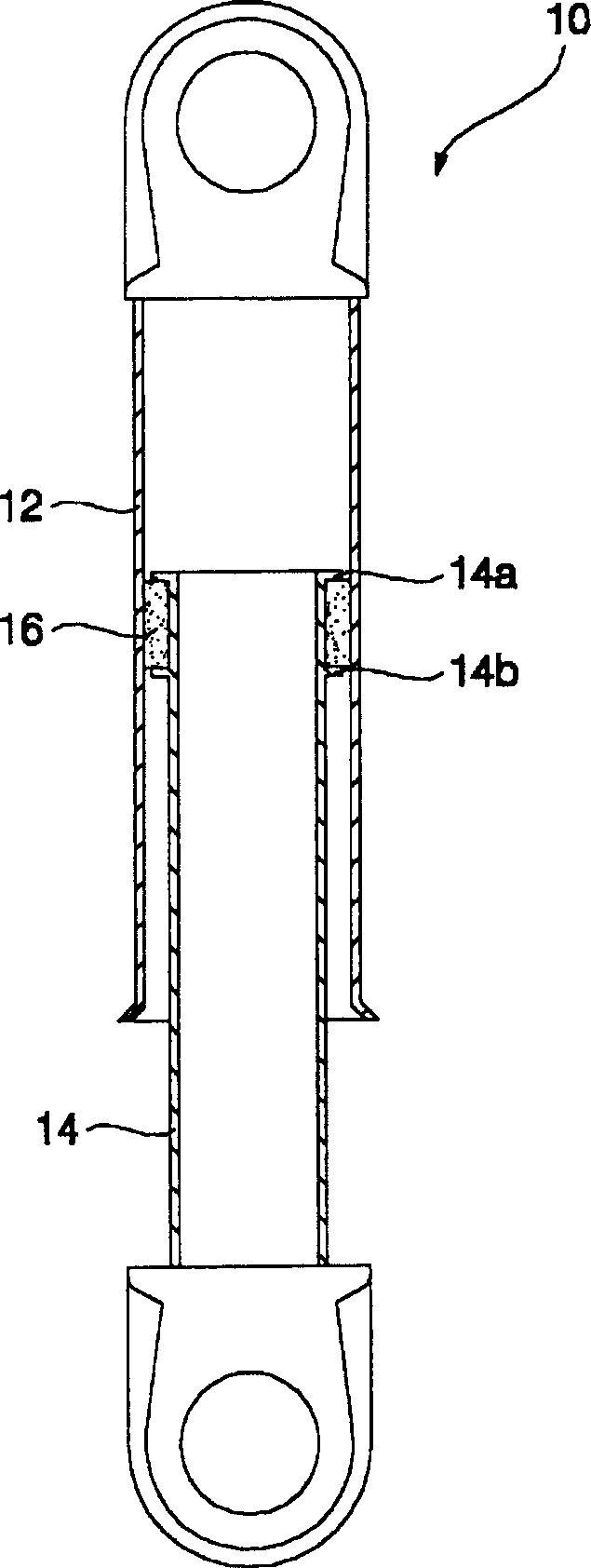

[0043] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0044] The drawings show various embodiments of the damper of a washing machine. Even in different drawings, the same or similar parts are denoted by the same reference numerals, and the above-mentioned marks may make the subject of the present invention somewhat different. If it is not clear, a detailed description of the above-mentioned marks will be omitted. Will see figure 1 The description is related to the structure of the washing machine, especially the parts and parts not shown.

[0045] The washing machine damper according to the present invention is installed between the washing tub 6 and the bottom plate 2a, wherein the washing tub 6 is filled with washing water for washing clothes; the bottom plate 2a is formed as the bottom of the cabinet 2 that defines the appearance of the washing machine. Through this installation method, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com