Rigidity variable elastic system simulating device

A technique for elastic systems and simulation devices, which is applied in the field of simulation devices and can solve problems such as stiffness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

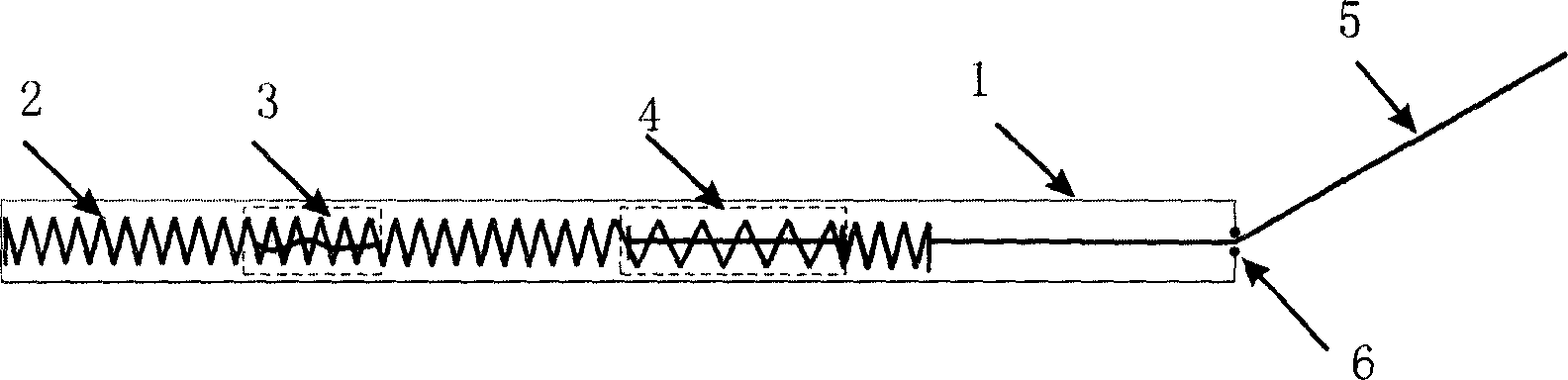

[0011] Such as figure 1 As shown, the present invention includes: a rigid shell 1 , a spring 2 , a spring limiting device 3 , a spring pretensioning device 4 , a cable 5 and a cable hole 6 . The connection relationship is as follows: the spring 2 is connected to the rigid shell 1, one end is connected to the tail end of the rigid shell 1, and the other end is connected to the cable 5, the cable 5 passes through the rigid shell 1 through the cable guide hole 6, and the spring limiting device 3 And the spring pretensioning device 4 is arranged on the spring 2 .

[0012] The spring limiting device 3 is a steel wire rope and clamps that are installed at both ends and can be fixed on the spring 2 .

[0013] The spring pretensioning device 4 is a rigid frame and a clip that is installed at both ends and can be fixed on the spring.

[0014] Cable 5 is a steel wire rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com