Adhesive resin composition and use thereof

A resin composition and adhesive technology, applied in the direction of synthetic resin layered products, epoxy resin glue, adhesive types, etc., can solve problems such as peeling and difficult recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

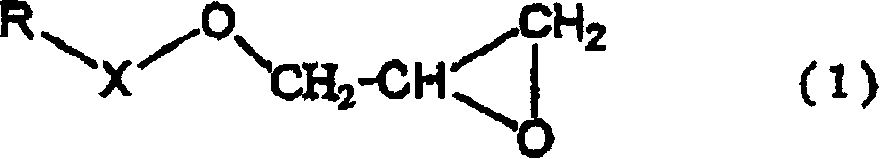

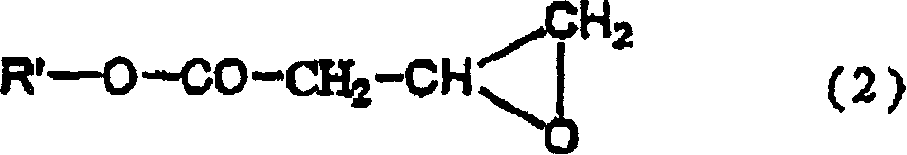

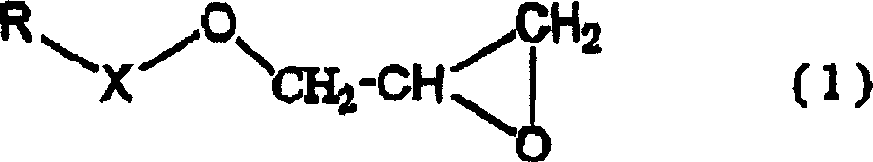

Method used

Image

Examples

manufacture example

[0104] The above-mentioned (A), (B) and (C) were added to the small batch kneader "Laborplast Mill" (manufactured by Toyo Seiki Seisakusho Co., Ltd.: 50C150, mixer: R100H) pre-kneaded at 10 rpm for 7 minutes at a cylinder set temperature of 100° C., and then main-kneaded at 50 rpm for 5 minutes to obtain an adhesive resin composition.

[0105] (2): Production example of adhesive laminated film

[0106] After hot pressing the adhesive resin composition obtained in (1) under the preforming conditions described below, the SUS plate and the fluororesin sheet were sequentially stacked on the hot plate of the hot press machine preheated to 100°C, A polyethylene terephthalate template and the obtained preform were placed on the fluororesin sheet, then the fluororesin sheet was placed, and then a SUS (stainless steel) plate was placed, and hot pressing was carried out in accordance with the film forming conditions described below to obtain Adhesive film.

[0107] Next, the film-like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com