Printer capable of regulating ink-jet energy according to ink-jet head temperature and relative regulating method

A technology of printers and inkjet heads, which is applied in printing and other fields, can solve the problems of high circuit cost, occupying printers, and inability to effectively improve printer performance, so as to achieve the effect of improving overall performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

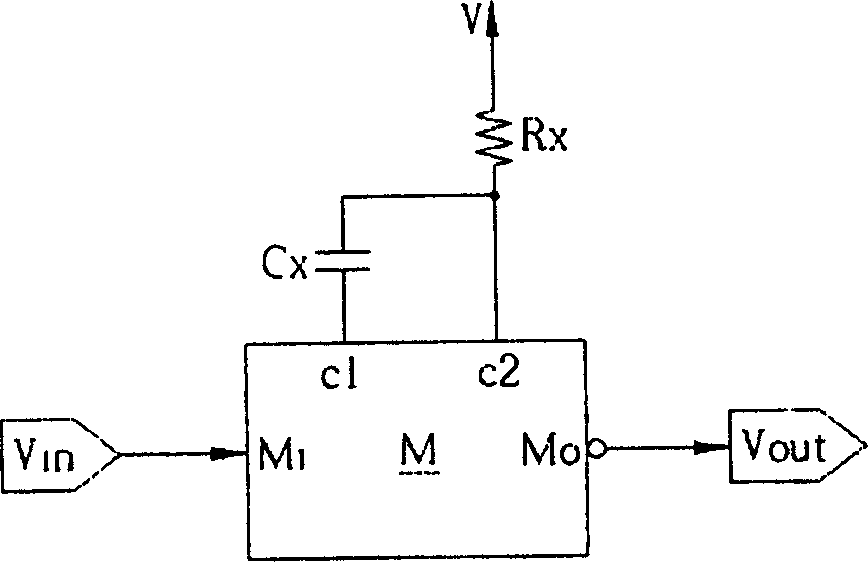

[0047] In a preferred embodiment of the present invention, the present invention uses a monostable trigger to directly adjust the pulse width of the print enable signal maintained at the enable level according to the resistance value of the thermistor. Please refer to image 3 , Figure 4 . image 3 is a schematic diagram of the relevant configuration of a typical monostable flip-flop M in operation, Figure 4 then image 3 Schematic diagram of the time series of relevant signal waveforms when the monostable flip-flop M is in operation; the horizontal axis of each waveform is time, and the vertical axis is the magnitude of the waveform amplitude. A typical monostable flip-flop M has an input terminal Mi, an output terminal Mo and two connection terminals c1 and c2. The input terminal Mi is used to receive an input signal Vin (such as an input voltage signal); the output terminal Mo is used to output an output signal Vout. The two connecting terminals c1 and c2 are used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com