Chip ball grid array packaging structure

A technology of ball grid array and packaging structure, which is applied in the direction of electrical components, electric solid devices, circuits, etc., and can solve the problems affecting the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

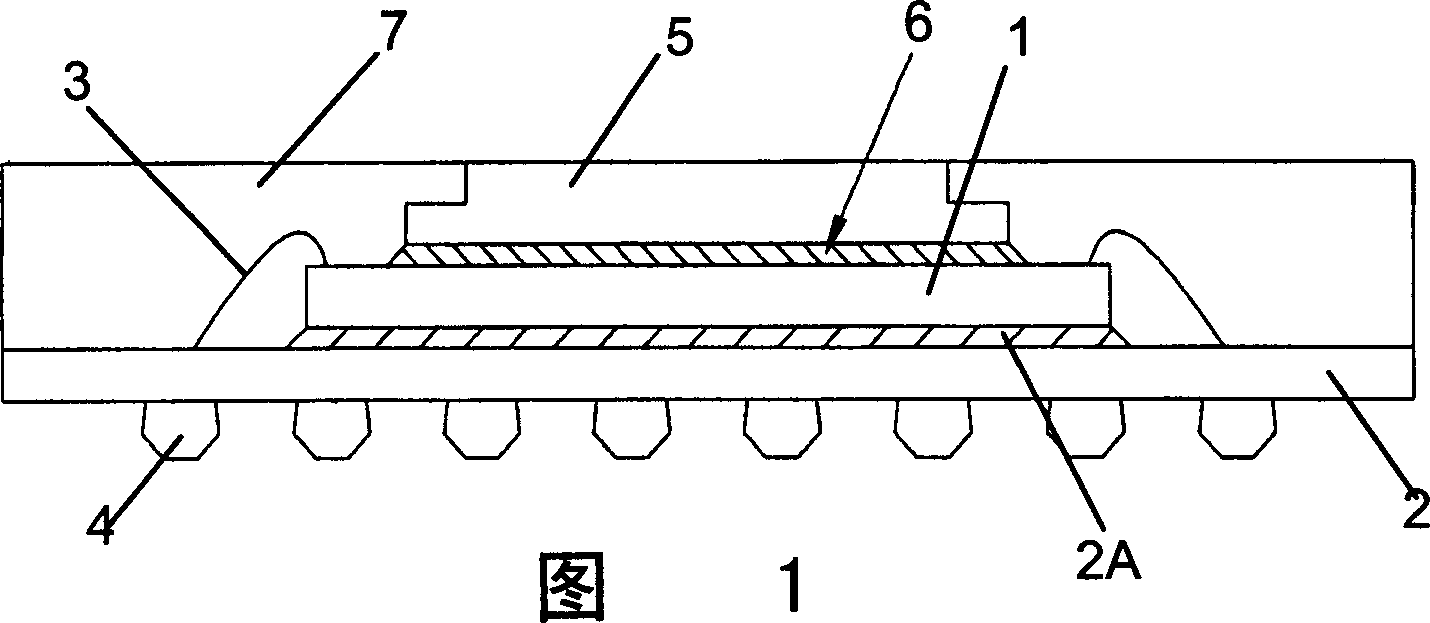

[0013] As shown in FIG. 1 , FIG. 1 shows a schematic diagram of a ball grid array package structure of the present invention. In FIG. 1, a chip 1 is bonded to a substrate 2 by an adhesive 2A or the like in a conventional method. Gold wires 3 electrically connect the circuitry on chip 1 to solder balls 4 under substrate 2 . The improvement of the present invention is that one side of the heat sink 5 is directly bonded to the surface of the chip 1 through the adhesive 6 . Then use the plastic package 7 to package the above-mentioned parts together.

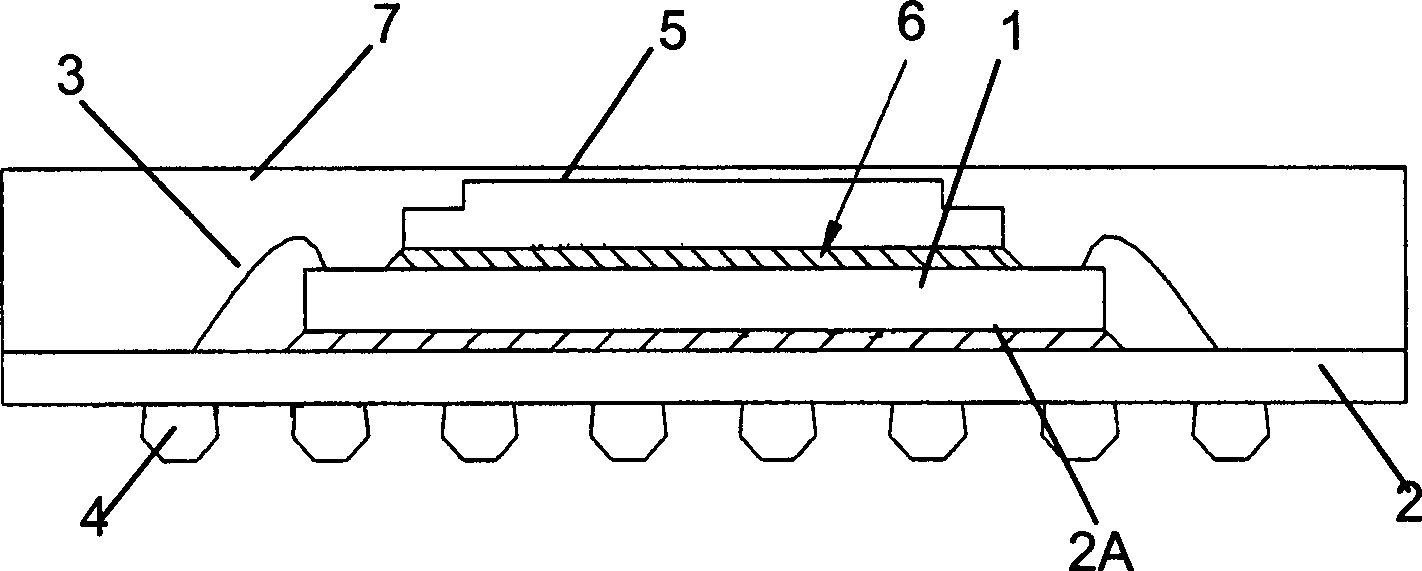

[0014] In the embodiment shown in FIG. 1 , the other surface of the heat sink 5 is exposed outside the plastic package 7 . Of course, you can also figure 2 In the illustrated embodiment, the heat sink 5 is not exposed outside the plastic package 7 .

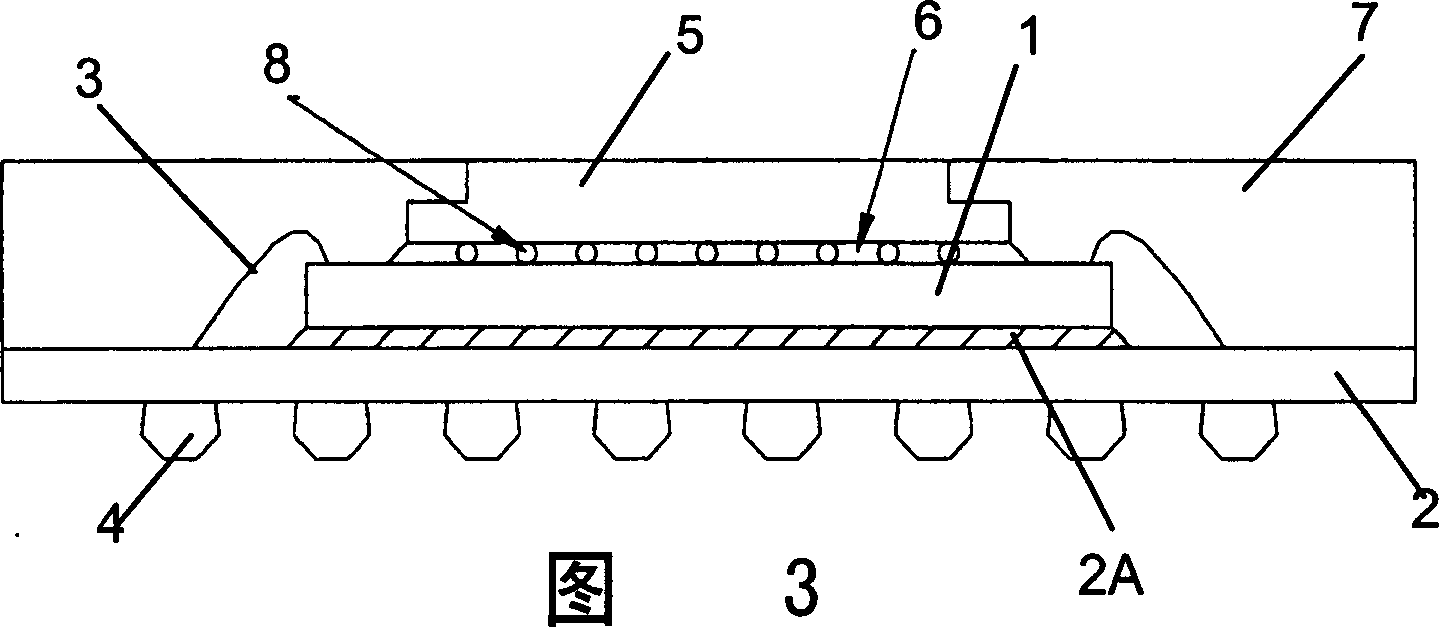

[0015] In Figure 1 and figure 2 In the shown embodiment, the adhesive 6 between the heat sink 5 and the chip 1 is an adhesive, however, as shown in FIG. 3 , some solid particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com