Bait casting machine for cage culture

A technology of cage culture and bait casting machine, which is applied in the application, fish farming industry, accessories for fishing, etc., can solve the problem that the bait casting of large deep-water cages cannot be fully satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

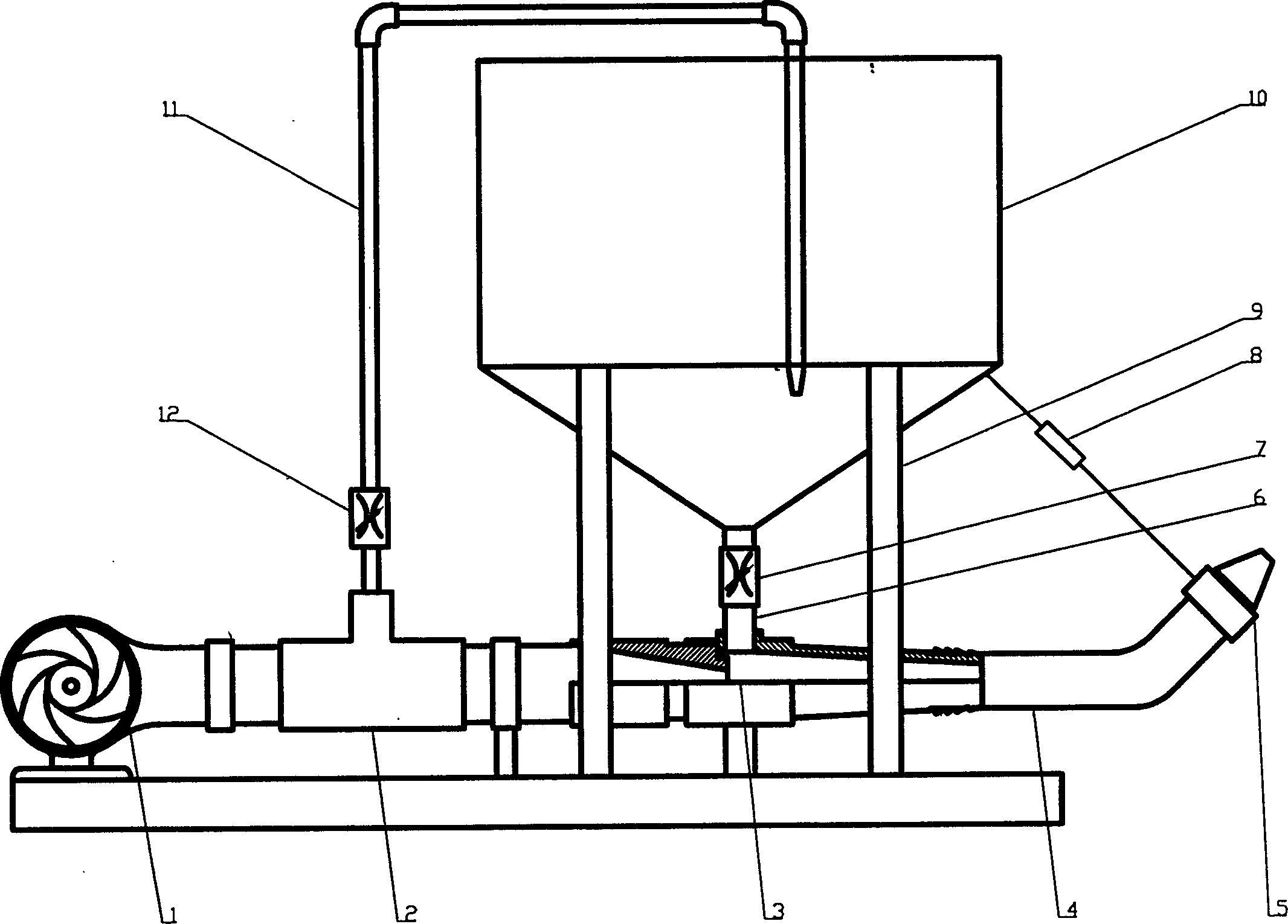

[0007] The bait feeder for net cage cultivation of the present invention has a diesel engine or a gasoline engine water pump 1, which is connected with a three-way valve 2, and the three-way valve 2 is communicated with the bait bin 10 through the flushing control valve 12 and the flushing pipe 11 all the way, and the bait bin 10 The feeding pipe 6 communicates with the mixing chamber 3, and the feeding control valve 7 is installed on the outside of the feeding pipe 6; the other way connects the feeding hose 4 through the mixing chamber 3, and the latter has a nozzle 5 at one end and an angle controller 8 at one end. It is connected with the outer wall of the bait bin 10, and the other end is connected with the bait casting hose 4. The hydrodynamic energy rushes the bait in the bait bin 10 into the mixing chamber 3, and sprays the bait in the net cage through the flexible pipe 4 and the shower nozzle 5. The bait bin 10 adopts three columns 9 to carry out triangular support. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com