Rope brake for overspeed upgoing elevator

A rope clamp and elevator technology, which is applied in elevators, transportation and packaging, etc., can solve the problems of prolonged stopping time of axle boxes, large elevator running inertia, and small size, and achieves light weight, compact structure, and easy reset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

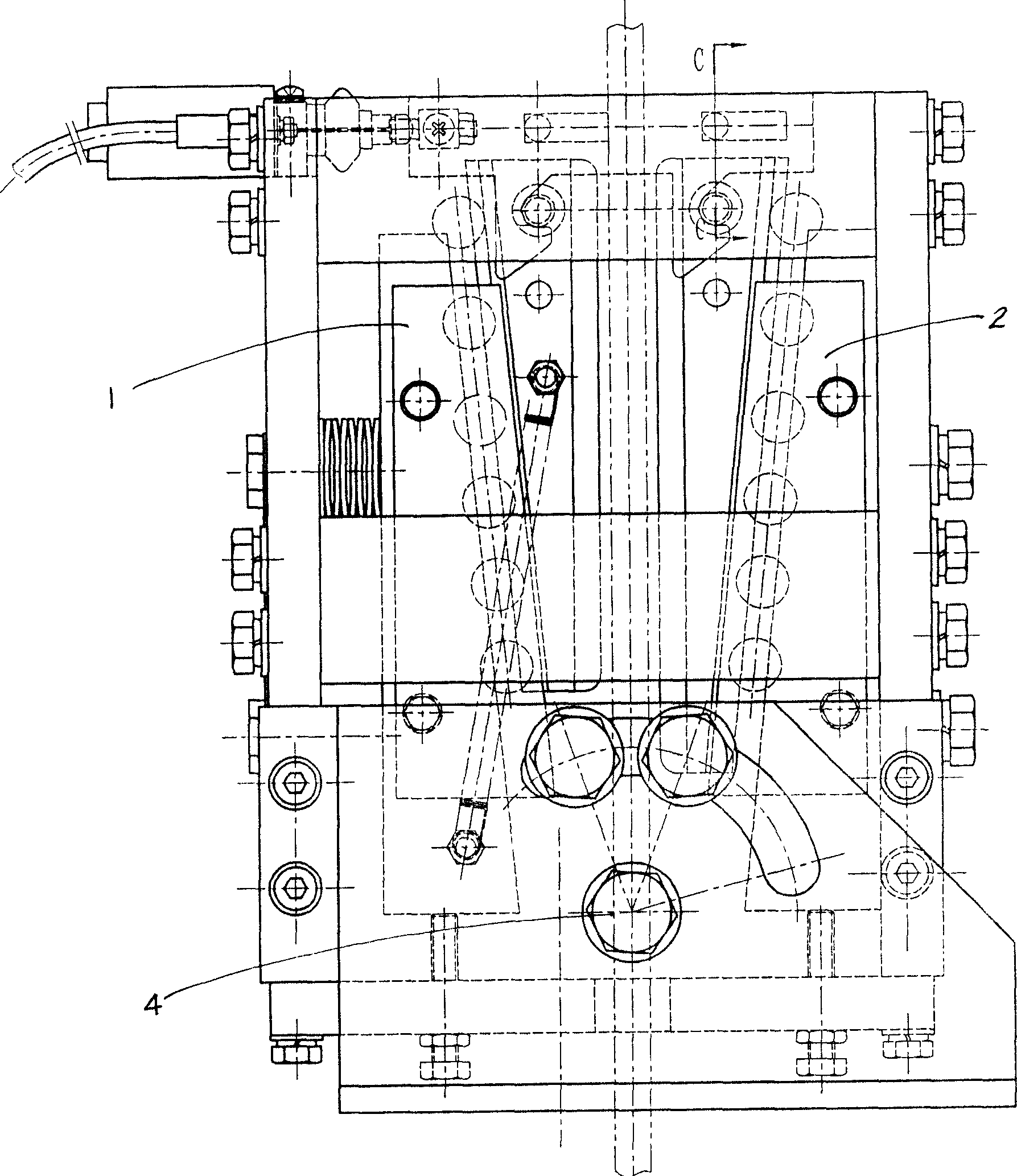

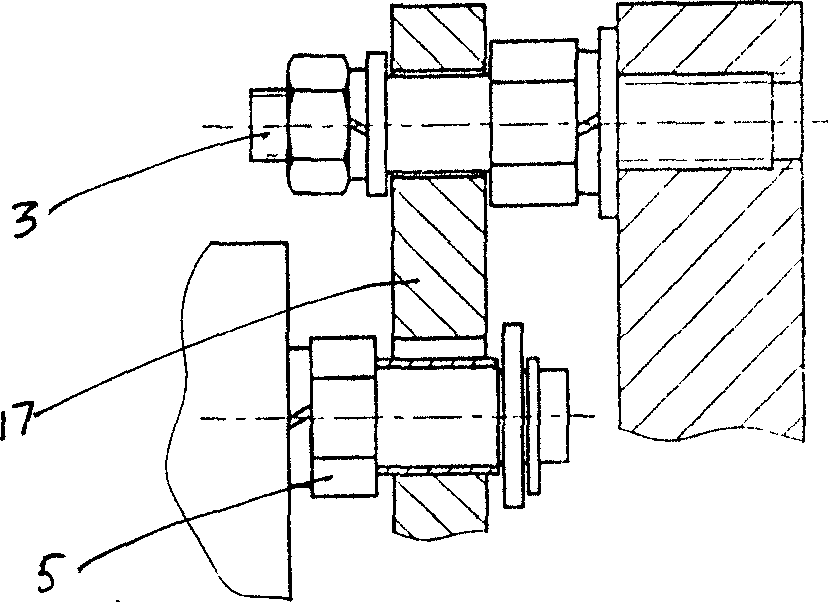

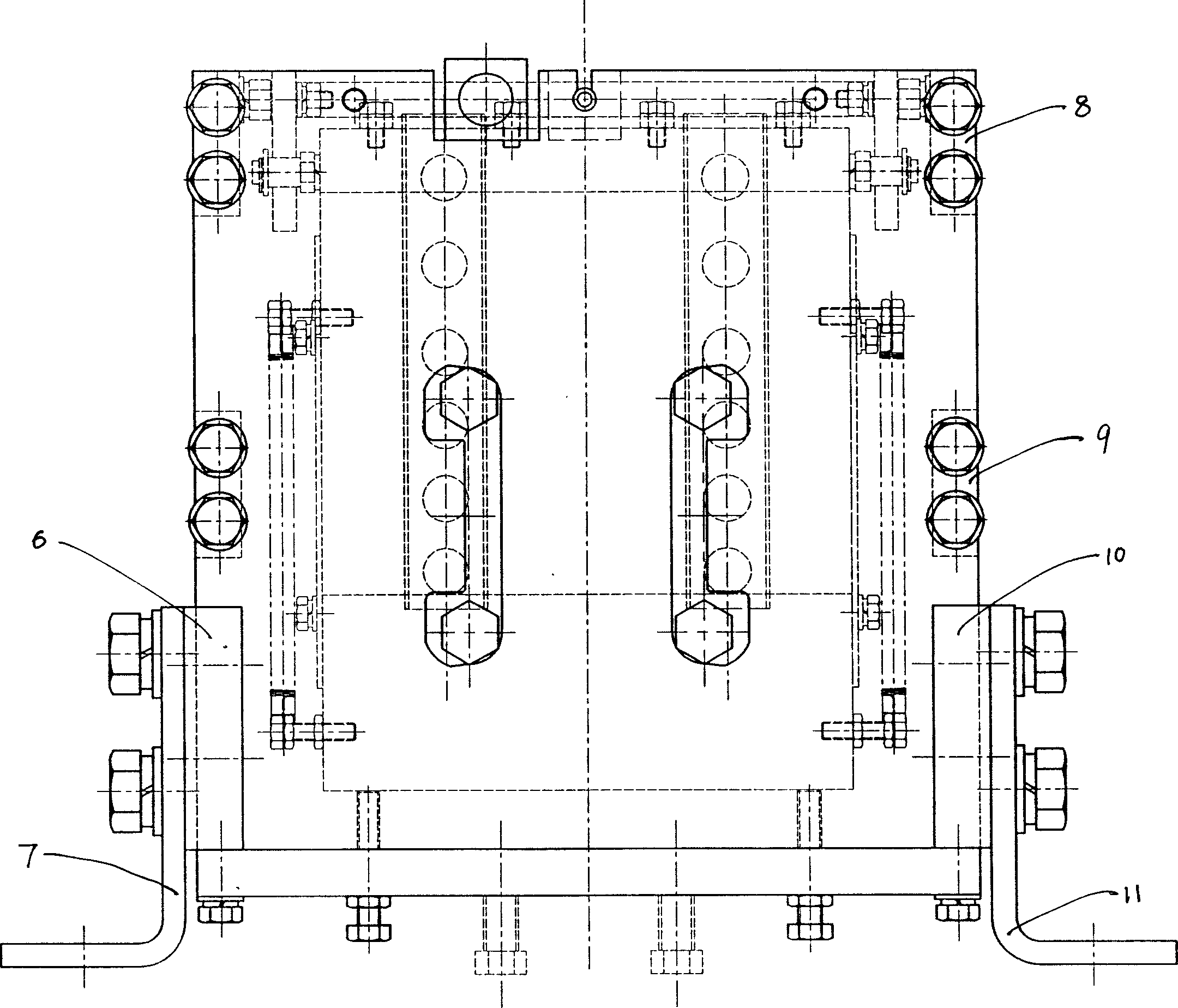

[0015] Depend on Figure 1-Figure 6 As shown, a kind of elevator upward speeding rope clamp 38 of the present invention is installed between the elevator traction wheel 37 and the guide wheel 39, and the other end of the elevator traction wheel 37 is the car 36; Above the counterweight 40 below, steel rope 35 passes in the middle of the upward overspeed rope gripper 38 of the elevator, and is positioned by positioning bolt 4; Rack base plate 26 and the frame main board 34 and the rack back plate 20 fixed on the rack base plate, and the upper, middle and lower rack side plates 8 fixed on the left and right sides between the rack main board and the rack back plate , 9, 10, and 6; a wedge-type wire rope clamping mechanism and a trigger mechanism are installed in the frame, and said clamping mechanism has movable wedges 33, 21, fixed wedges symmetrically arranged on the front and rear sides of the steel rope 35 Blocks 27, 24, liner plates 31, 22 are fixed on the movable wedge, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com