Substrate processing apparatus and cleaning method therefor

一种处理器件、衬底的技术,应用在清洁方法和用具、化学仪器和方法、半导体/固态器件制造等方向,能够解决流动变乱、均匀性变差、难清洗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0048] Hereinafter, the substrate processing device and its cleaning method according to the first embodiment of the present invention will be described with reference to the drawings.

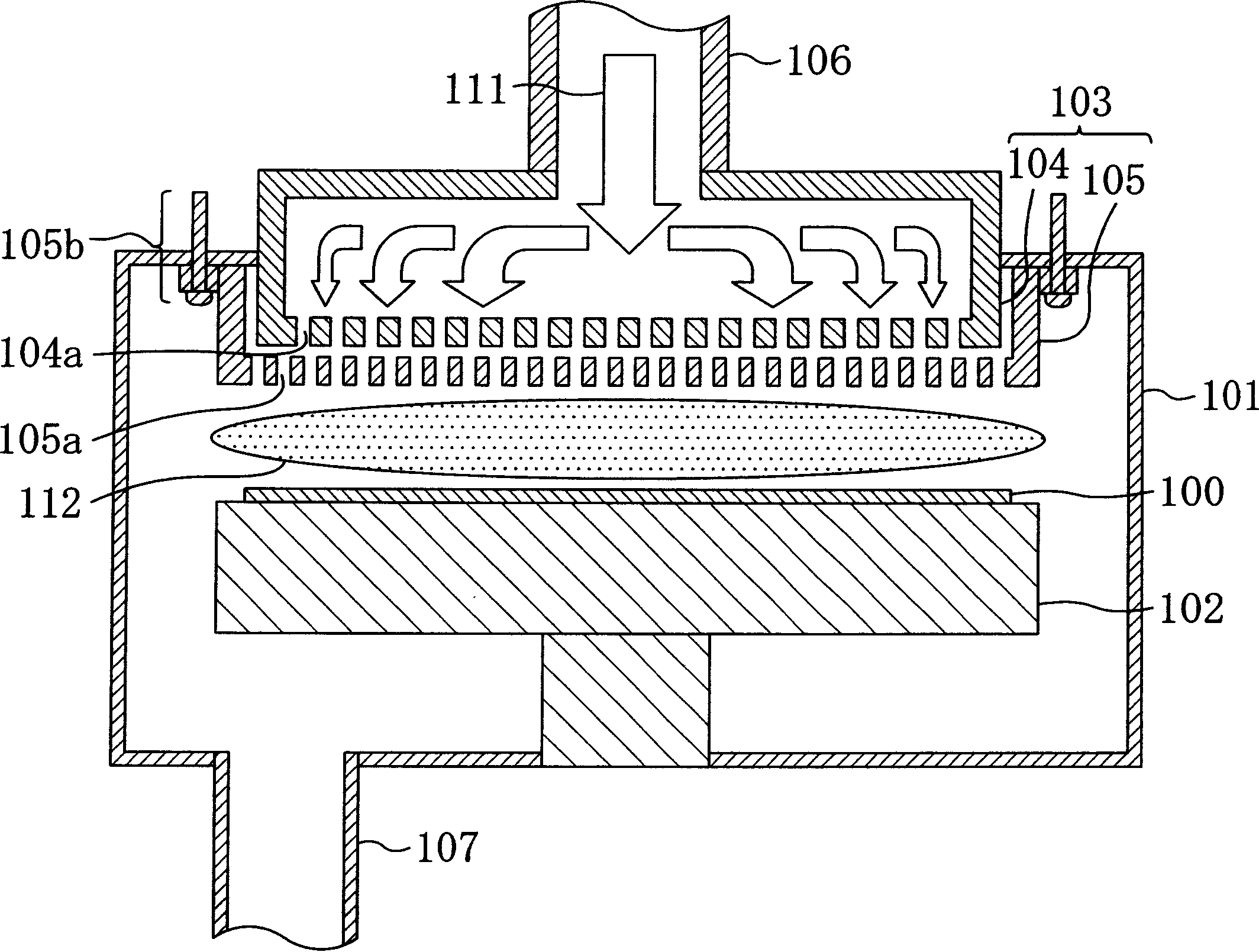

[0049] figure 1 and figure 2 A schematic cross-sectional structure of a substrate processing device (specifically, a chemical vapor growth device) according to the first embodiment is shown; figure 1 Indicates the internal state of the device during film formation, figure 2 Indicates the internal state of the device at the time of cleaning.

[0050] Such as figure 1 and figure 2 As shown, a lower electrode 102 serving also as a substrate support is provided at the bottom of the reaction chamber 101 . That is, the processed substrate (wafer) 100 is mounted on the lower electrode 102 . In addition, the reaction chamber 101 is a reaction chamber capable of decompression (a pressure state lower than normal pressure (atmospheric pressure) can be realized), and the lower electrode 102 in...

no. 2 Embodiment

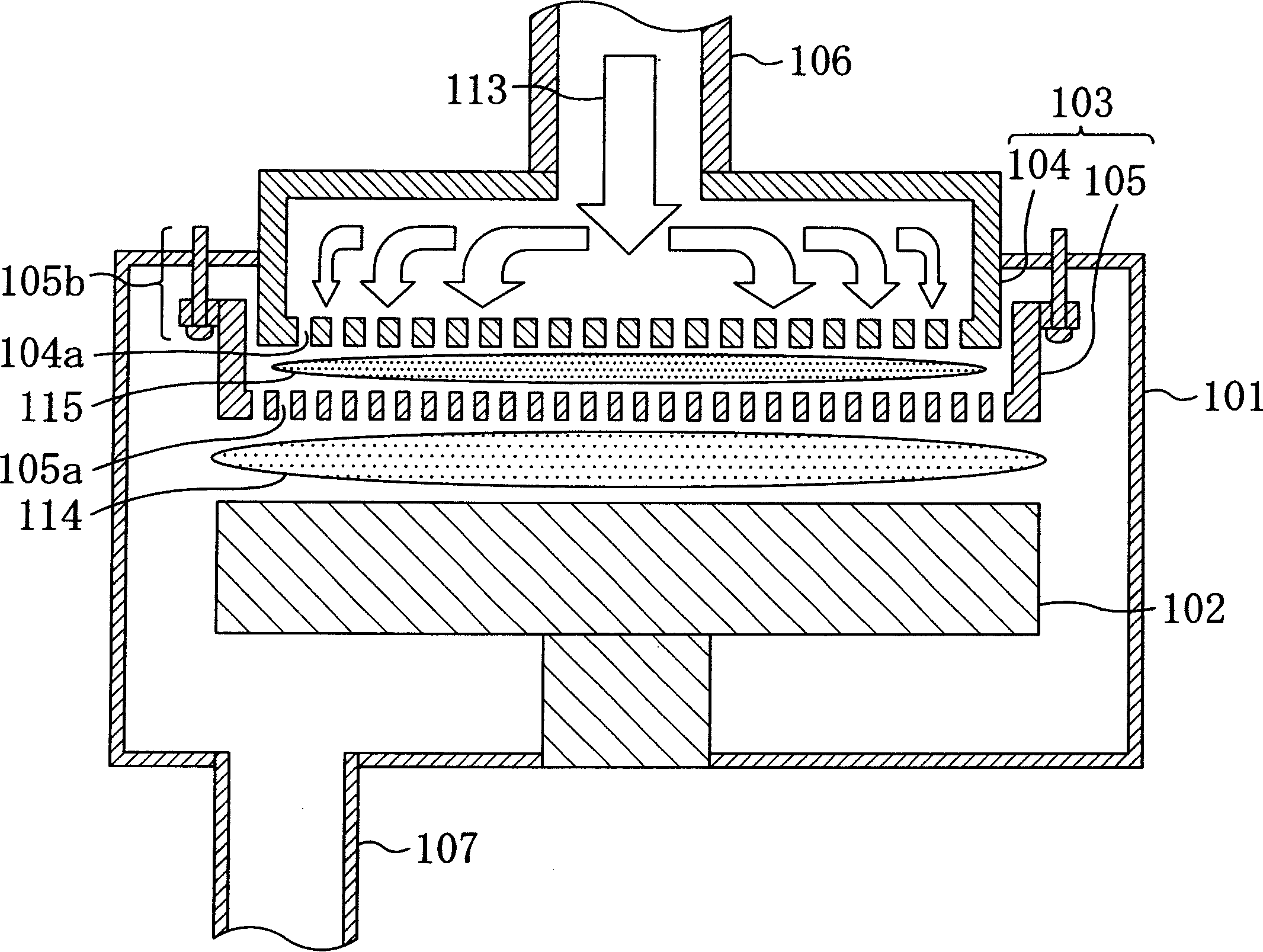

[0068] Hereinafter, a substrate processing device and a cleaning method thereof according to a second embodiment of the present invention will be described with reference to the drawings.

[0069] image 3 A schematic cross-sectional structure of a substrate processing device (specifically, a chemical vapor growth device) according to the second embodiment is shown. In addition, in image 3 in, for with figure 1 and figure 2 Components that are the same as in the first embodiment shown are denoted by the same symbols, and explanations thereof are omitted.

[0070] Such as image 3 As shown, in the substrate processing device of this embodiment, as in the first embodiment, the upper electrode 103 for generating plasma is composed of a baffle 104 and a flat plate 105. As a feature of this embodiment, the baffle The first heater 121 is attached to the inner wall surface of the side part of 104 , and the second heater 122 is attached to the outer wall surface of the side pa...

no. 3 Embodiment

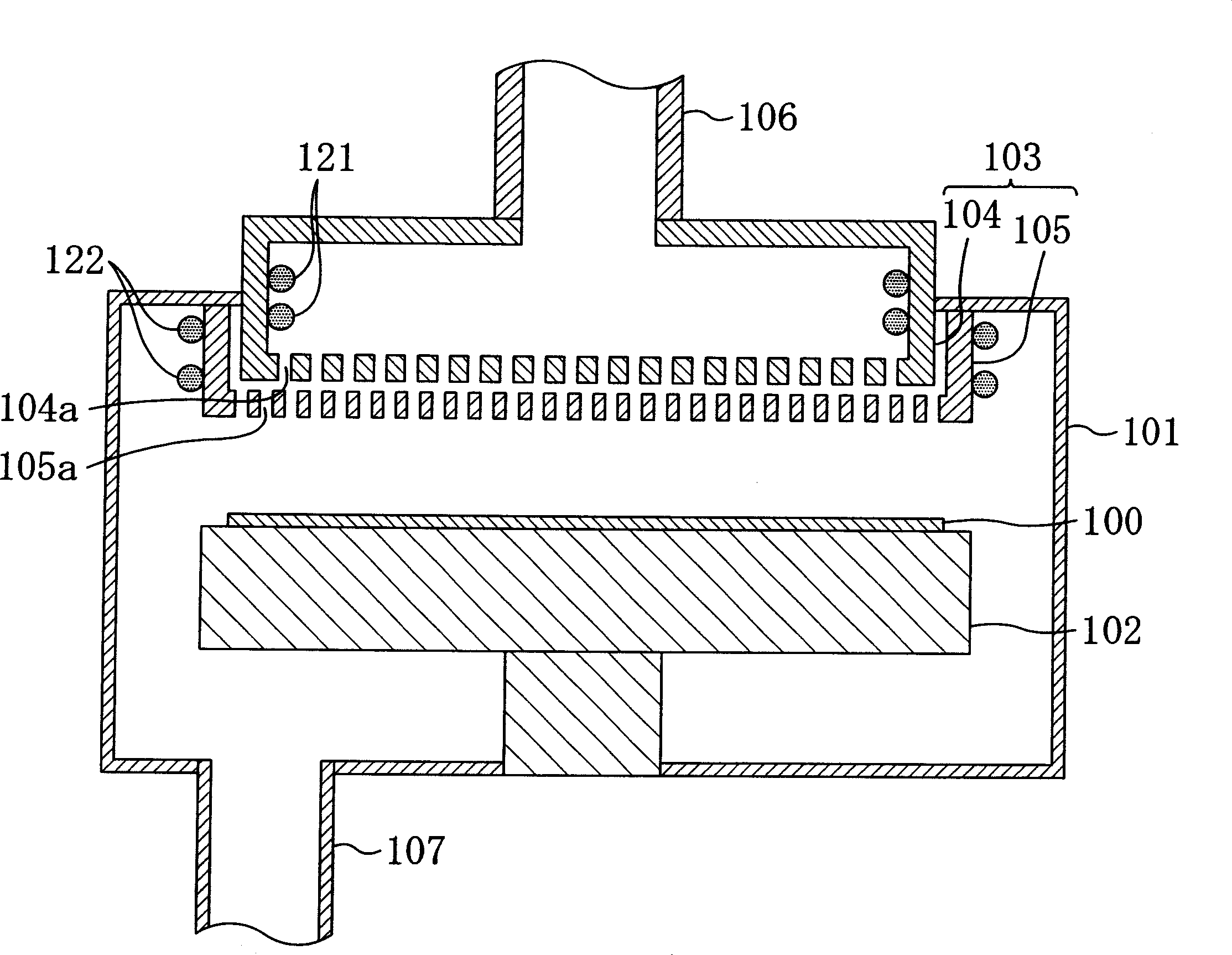

[0077] Hereinafter, a substrate processing device and a cleaning method thereof according to a third embodiment of the present invention will be described with reference to the drawings.

[0078] Figure 4 A schematic cross-sectional structure of a substrate processing device (specifically, a chemical vapor growth device) according to the third embodiment is shown. In addition, in Figure 4 in, right with figure 1 and figure 2 Components that are the same as in the first embodiment shown are denoted by the same symbols, and explanations thereof are omitted.

[0079] Such as Figure 4 As shown, in the substrate processing device of this embodiment, as in the first embodiment, the upper electrode 103 for generating plasma is composed of a baffle plate 104 and a flat plate 105, but as a feature of this embodiment, it can The ultrasonic vibration source 131 that transmits ultrasonic vibrations to the baffle 104 , that is, the upper electrode 103 is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com