Dehydration drying method and apparatus, and substrate processing apparatus

A technology of substrate processing device and drying method, which is applied in the direction of drying solid materials, drying chamber/container, and drying solid materials without heating, which can solve the problems of low-k film expansion, inability to achieve vacuum degree, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

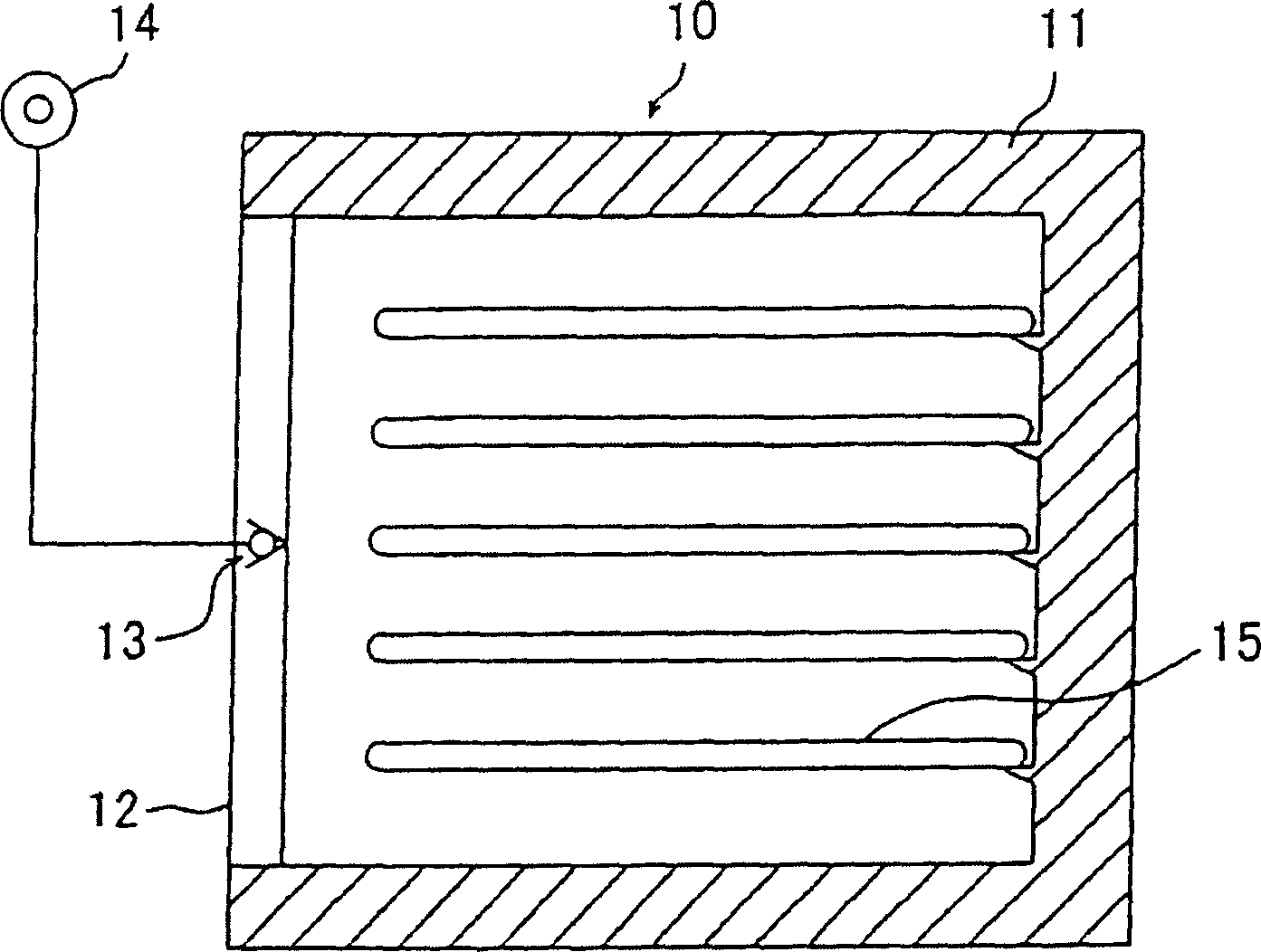

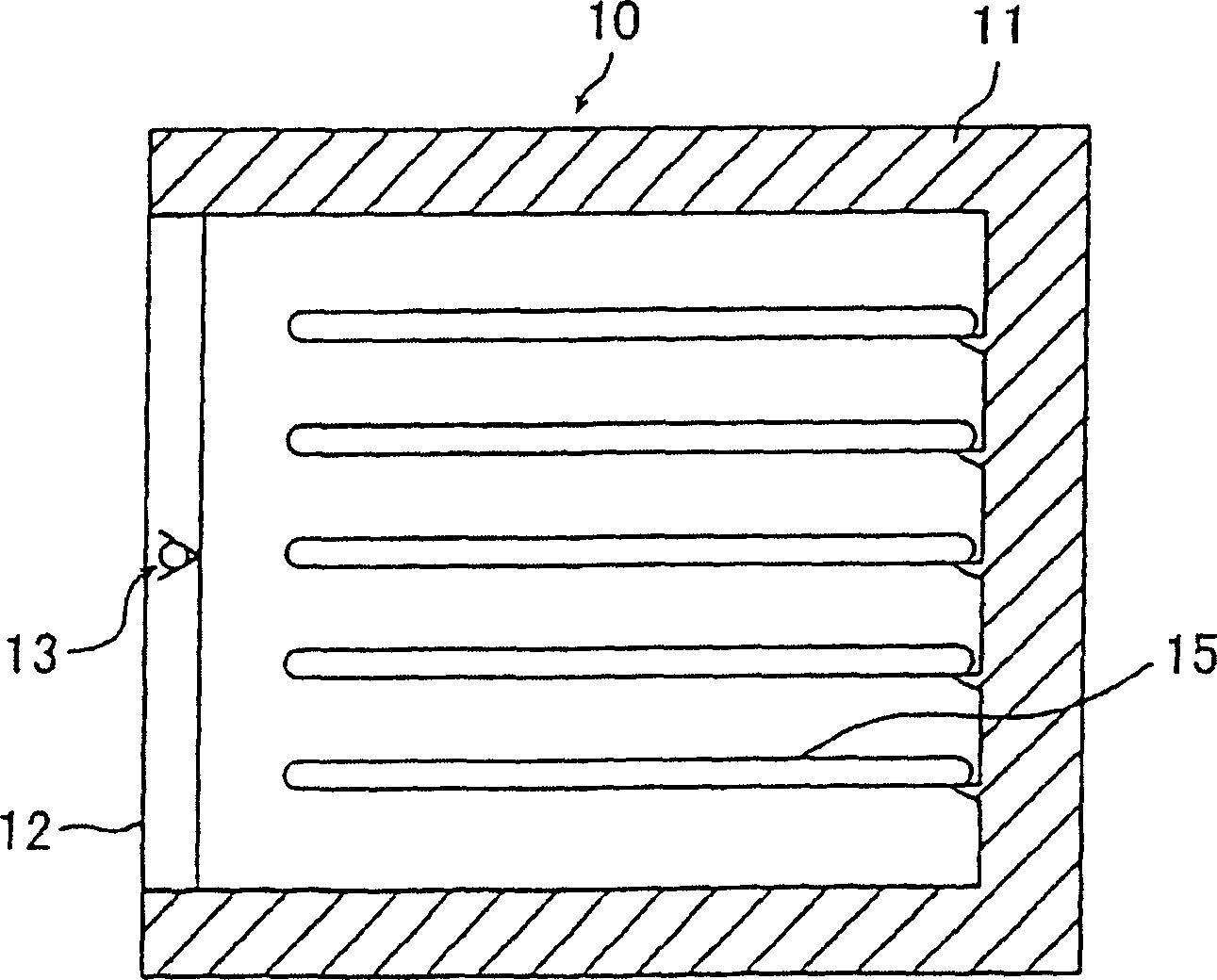

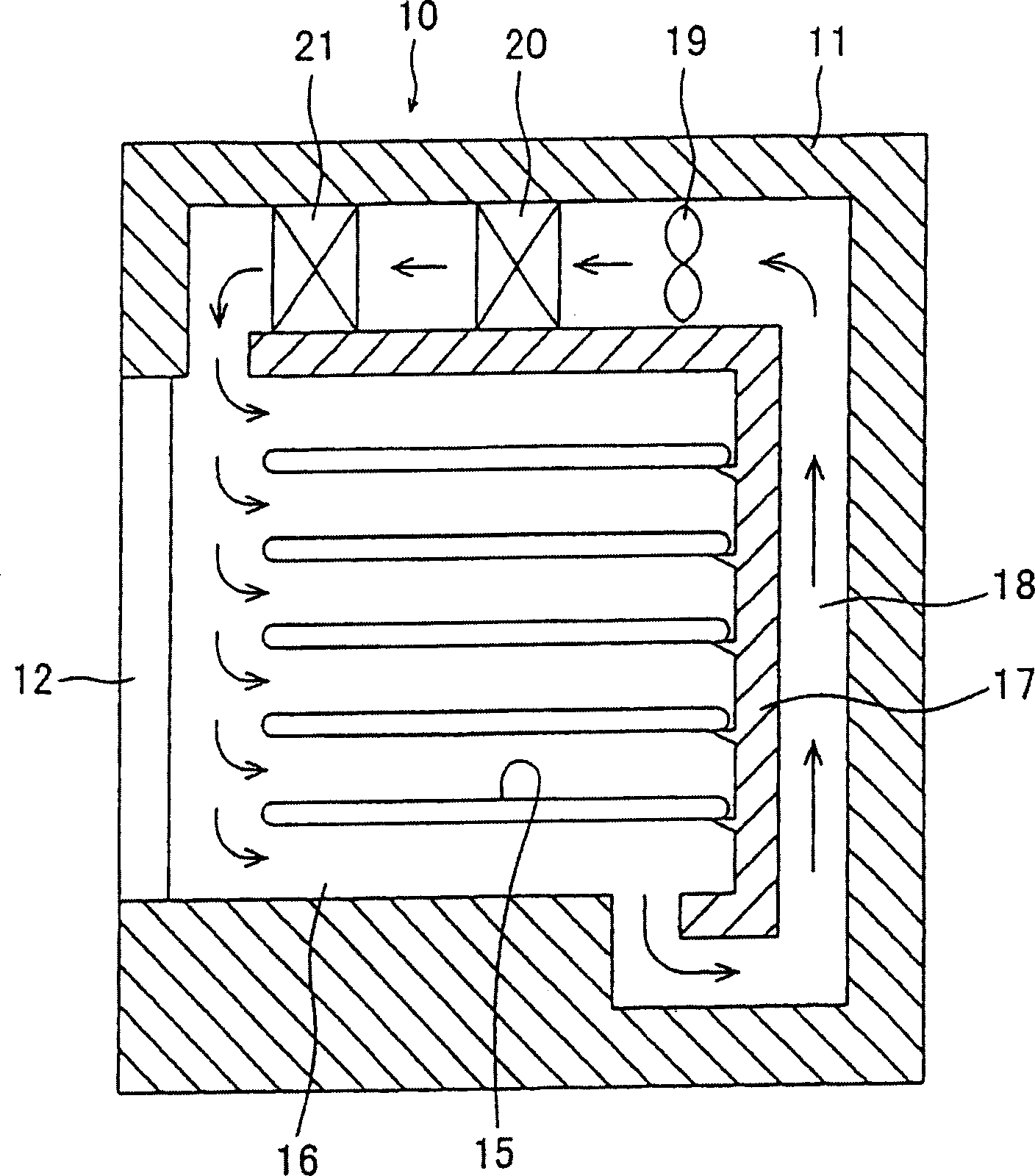

[0045] Hereinafter, a dehydration drying method, a dehydration drying apparatus, and a substrate processing apparatus according to embodiments of the present invention will be described with reference to the accompanying drawings. Figure 1A and 1B is a schematic cross-sectional view showing a dehydration drying apparatus for performing a method of dehydration and drying a substrate according to a first embodiment of the present invention. Such as Figure 1A and 1B As shown, a carrier 10 is used to accommodate and carry a substrate 15 between devices in a semiconductor fabrication facility. The carrier 10 includes a carrier body (body member) 11 having an opening defined in its side wall, and a cover 12 for sealingly closing the opening of the carrier body 11 . The cover 12 has a check valve 13 for allowing the inner space of the carrier body 11 to communicate with a vacuum source 14 . The carrier body 11 is capable of accommodating a plurality of substrates 15 at predetermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com