Light guide board and its manufacturing method

A manufacturing method and technology of light guide plates, applied in optics, nonlinear optics, instruments, etc., can solve problems such as cumbersome manufacturing process, and achieve the effect of simple manufacturing process and uniform brightness of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

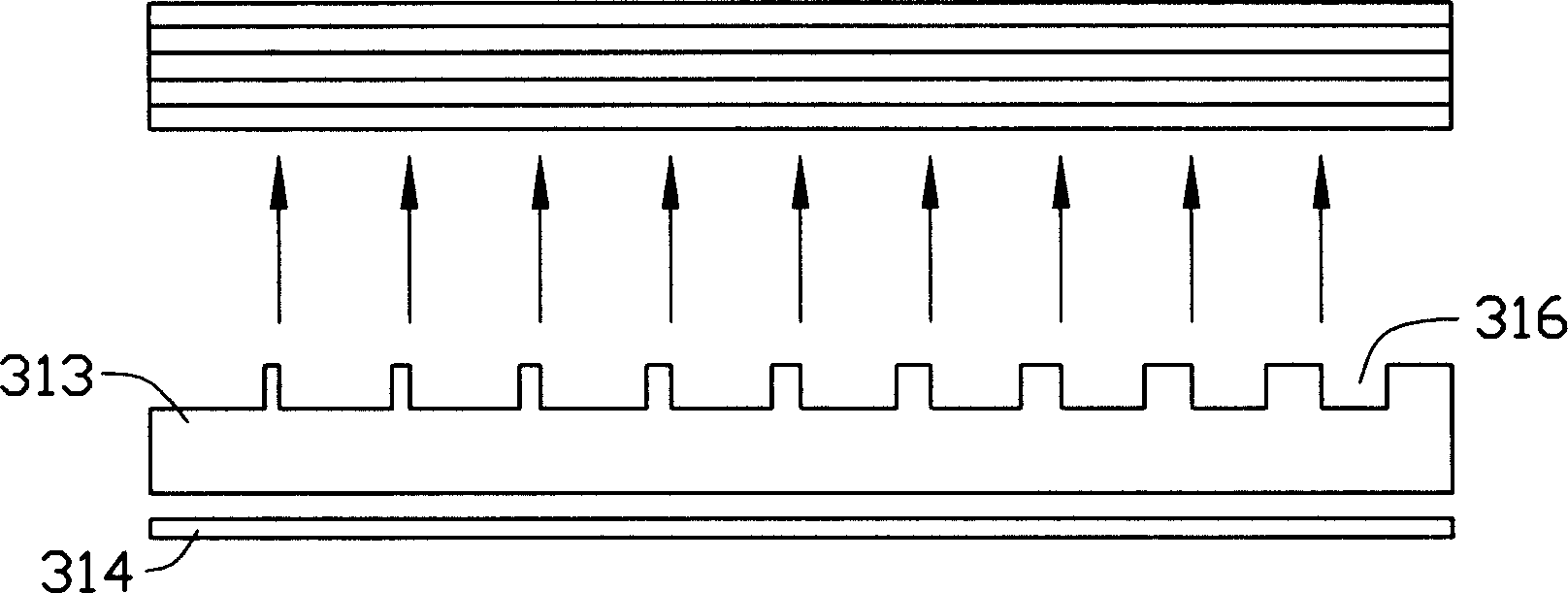

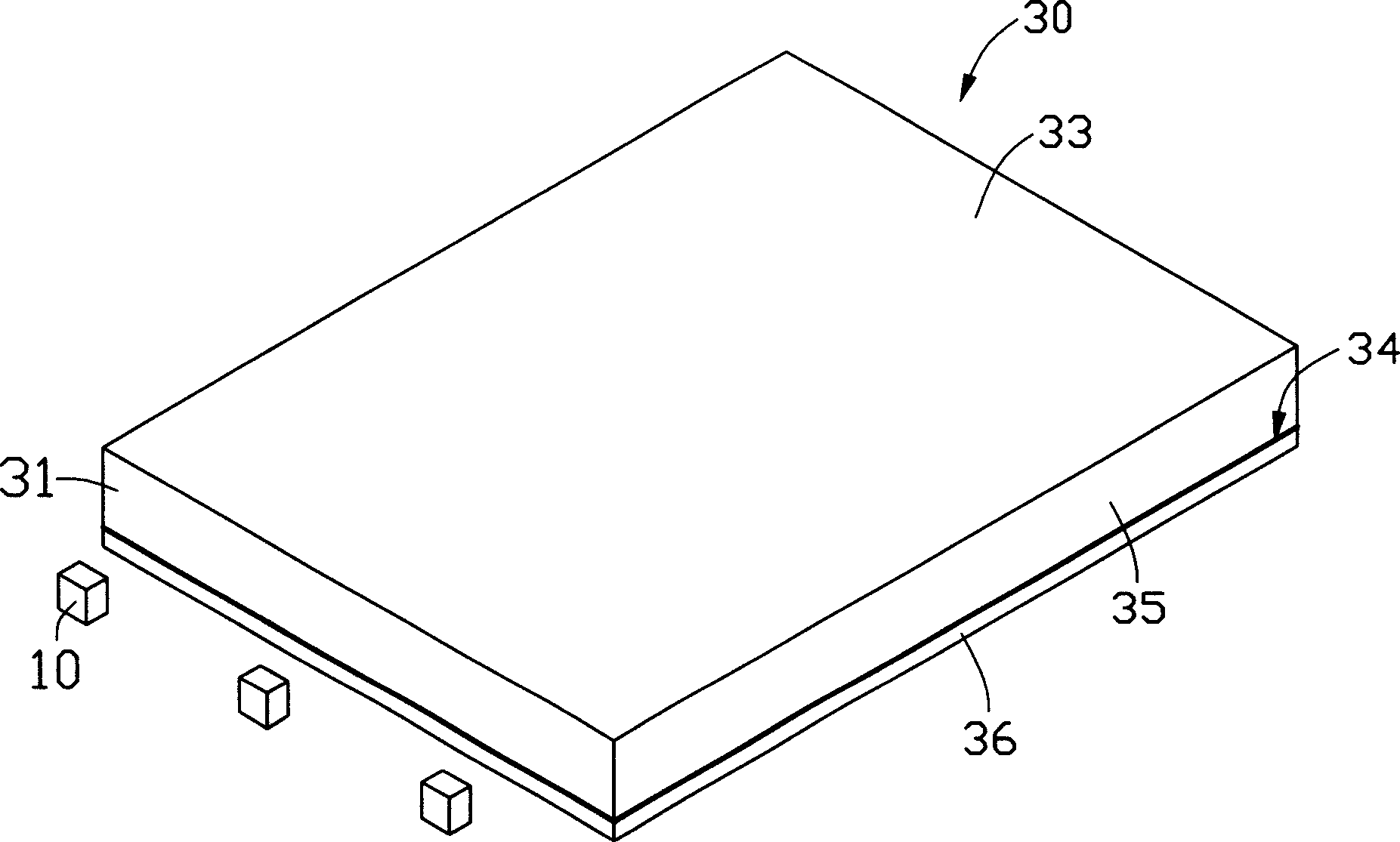

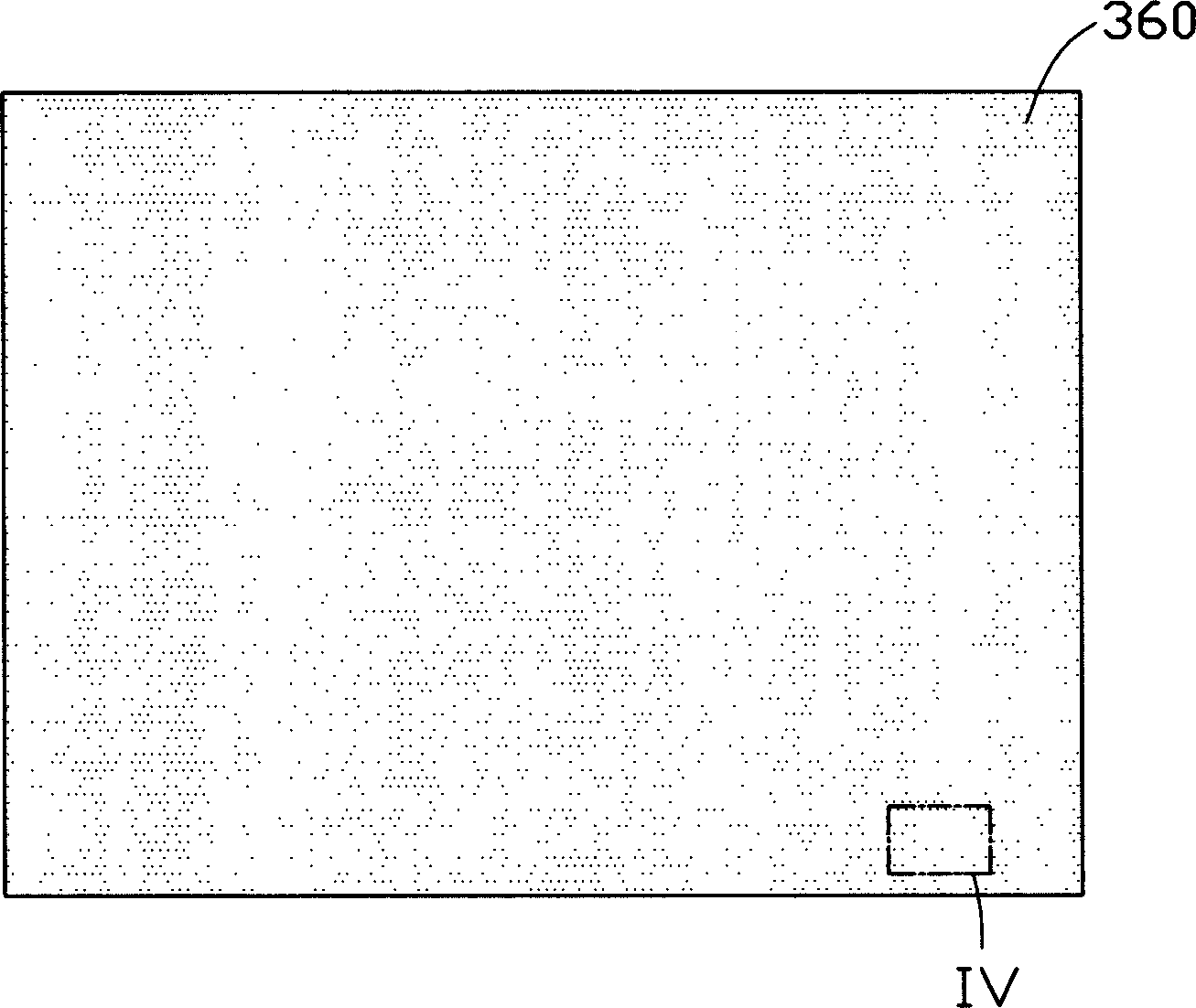

[0017] see figure 2 The light guide plate 30 of the present invention includes a light incident surface 31, a light exit surface 33 intersecting the light incident surface 31, a bottom surface 34 opposite to the light exit surface 33, and a plurality of side surfaces 35, and a reflective aluminum foil hologram 36 passes through the light guide plate 30 A transparent material (not shown) with matching refractive index is attached on the bottom surface 34 of the light guide plate 30 . The light emitted from the light source 10 enters the light guide plate 30 from the light incident surface 31 , passes through the transparent material through the bottom surface 34 of the light guide plate 30 , is diffracted by the reflective aluminum foil hologram 36 , and then uniformly exits from the light exit surface 33 . There should be no air gap between the light guide plate 30 and the reflective aluminum foil hologram 36, so that the light in the light guide plate 30 is directly emitted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com