Distributing device for electric slide form concrete lining machine

A technology of distributing device and concrete, which is applied in the processing of building materials, water conservancy projects, artificial waterways, etc., can solve the problems of large maintenance workload, huge equipment, long installation and disassembly cycle, etc., and achieves convenient installation and disassembly and maintenance workload. Less, superior performance and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

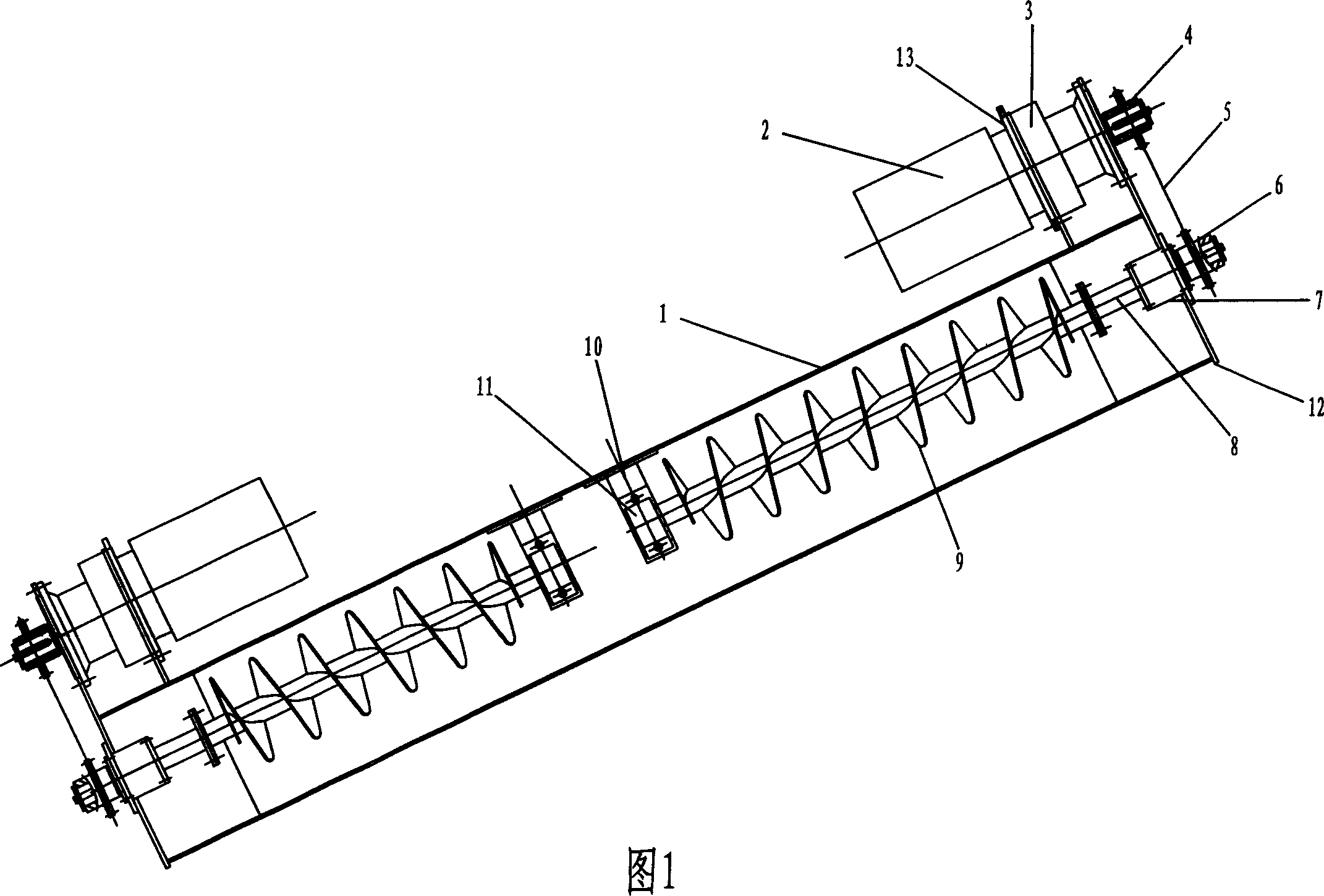

[0013] As shown in Fig. 1, the structure of the present embodiment is: it is made up of two sets of screw distributors on the left and right, they all have identical spare parts to assemble, and its installation support form is identical. Take the screw distributor on the right as an example: the drive motor 2 and the reducer 3 are directly connected, the front end of the reducer is connected to the end plate 12 of the silo by flange bolts, and the ring flange 13 is set on the body and connected by bolts On the support plate 1, the reducer is firmly supported; the output shaft of the reducer is equipped with a sprocket 4, the right end of the transmission shaft 8 is equipped with a sprocket 6, and the left end has a flange; the right end of the spiral hinge cage 9 has a flange It is rigidly connected with the transmission shaft 8 bolts, its left end is supported on the bearing seat 11, the right end is supported on the bearing 7, and the support seat 10 is welded on the rear ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com