220 KV single phase railway traction transformer structure

A railway traction and transformer technology, applied in transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of high operating costs, achieve strong over-excitation operation capability, strong resistance to frequent short circuits, and overload operation powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

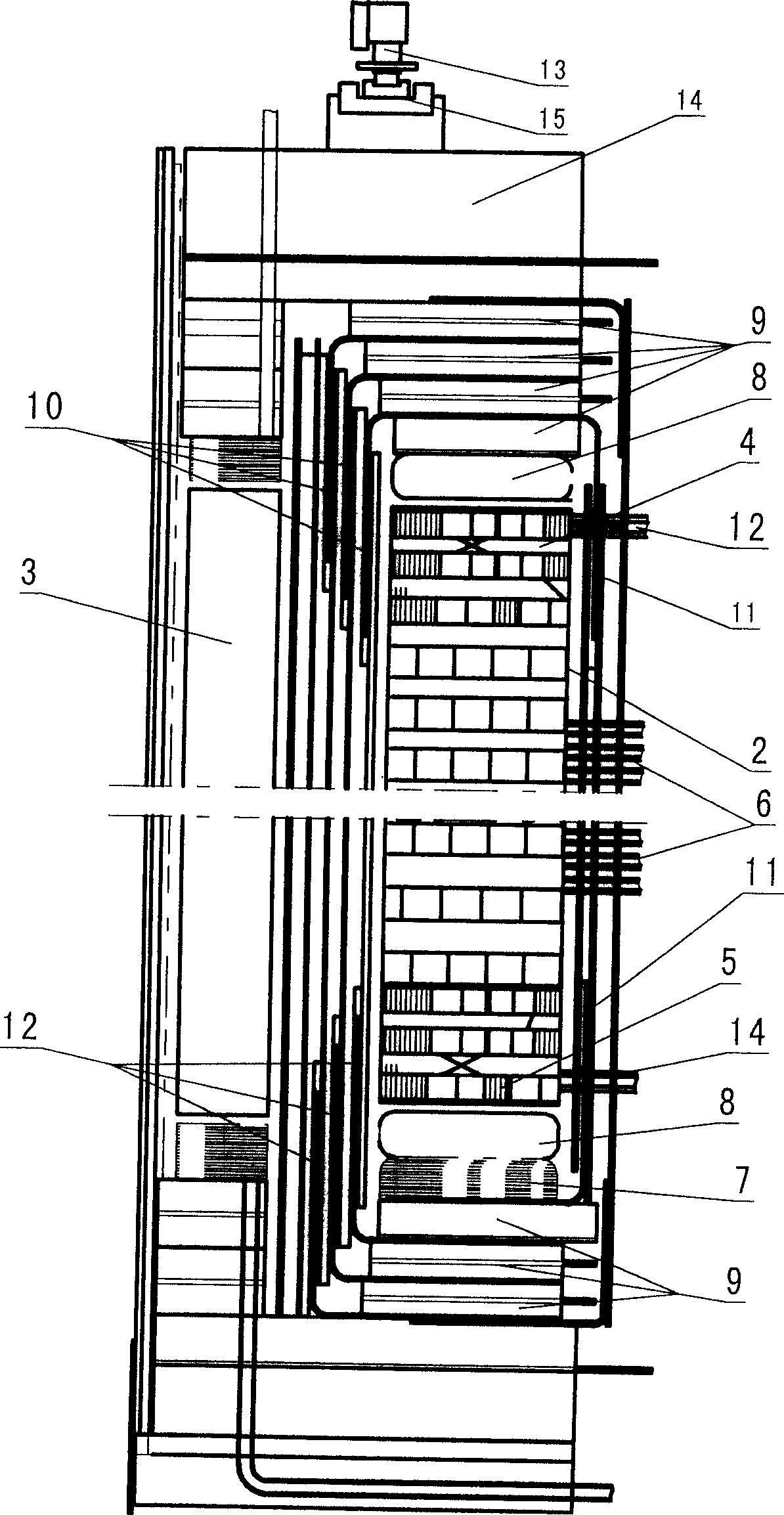

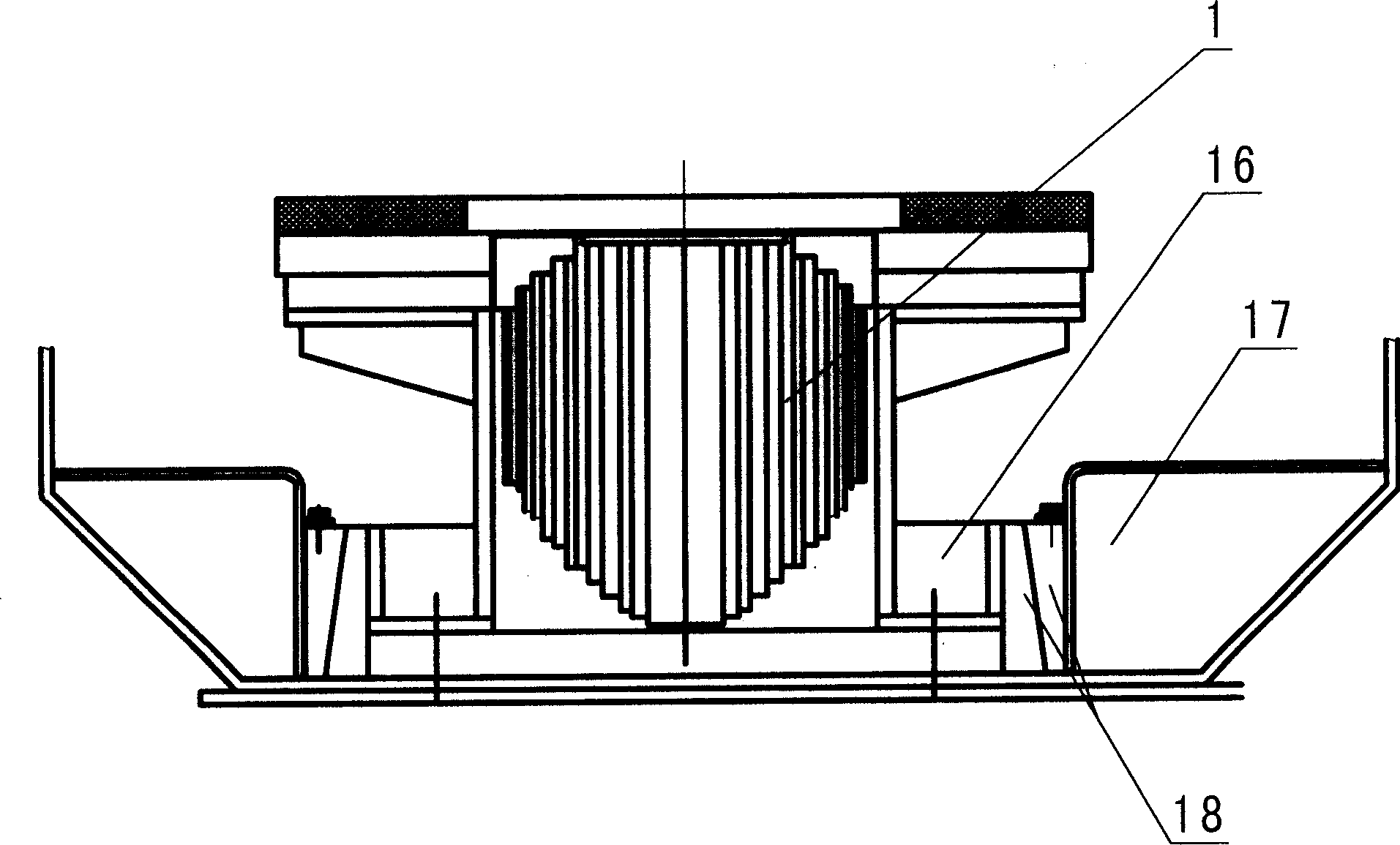

[0012] The present invention is a 220kV class single-phase railway traction transformer body structure, which mainly includes an iron core (1), a high-voltage coil (2), a low-voltage coil (3) and the like. The voltage of the high-voltage coil head (5) and the high-voltage coil end (6) is both 220kV. In order to make the electric field evenly distributed, the body structure adopts a fully insulated design. In order to reduce the impact gradient of the electric field at the end and increase the capacitance at the end of the coil, both the head end (4) and the end (5) of the high-voltage coil are wound with entangled equal turns, and the other line segments of the high-voltage coil (2) are wound in a continuous manner. In order to ensure that the structure of the upper and lower parts of the high-voltage coil (2) is completely symmetrical, the ampere-turn distribution is even and balanced, and the short-circuit resistance of the transformer coil is improved, the tap section (6) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com