Thermal insulation optical cable power transmission hybrid cable

A hybrid cable and optical cable technology, applied in cables, circuits, power cables, etc., can solve the problems of affecting the transmission performance of optical fibers, lack of thermal insulation effect, and low adaptability of optical fibers, etc. Overcome the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

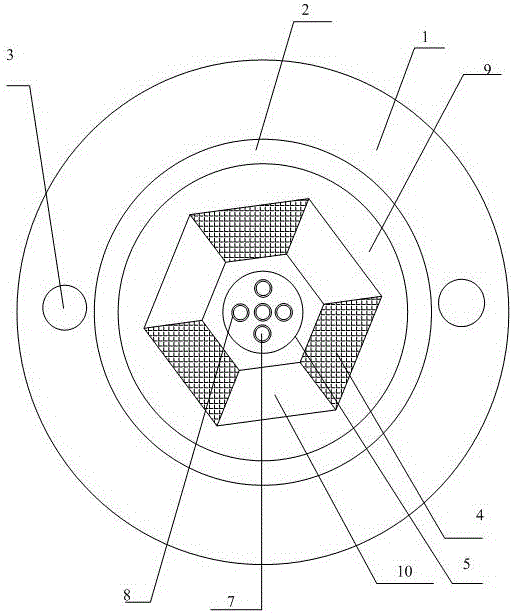

[0026] Such as figure 1 shown.

[0027] Heat-insulated optical cable power transmission hybrid cable, including a filling layer 9 with an optical fiber component and an isosceles trapezoidal module inside, the filling layer 9 is covered with an insulating layer 2, the insulating layer is covered with a PE outer sheath 1, and the optical fiber component includes The loose tube 5 is provided with a fiber paste layer 6 inside the loose tube, and the fiber paste layer 6 is provided with an optical fiber 7 whose outer surface is coated with an optical fiber surface coating glue 8. There are 6 isosceles trapezoidal modules, and 6 isosceles trapezoidal modules The module includes 3 electric wires with isosceles trapezoidal cross-section and 3 spacers with isosceles trapezoidal cross-section. Adjacent electric wires are set at intervals by spacers, and all isosceles trapezoidal modules are enclosed to form a A hexagonal polygonal ring with a hexagonal inner diameter, the loose tube i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com