System and its method for high efficiency ozone water cleaning semiconductor wafer

An ozone water and high-efficiency technology is applied to a system and its field for cleaning semiconductor wafers with high-efficiency ozone water. Effects of Metal Contamination Concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

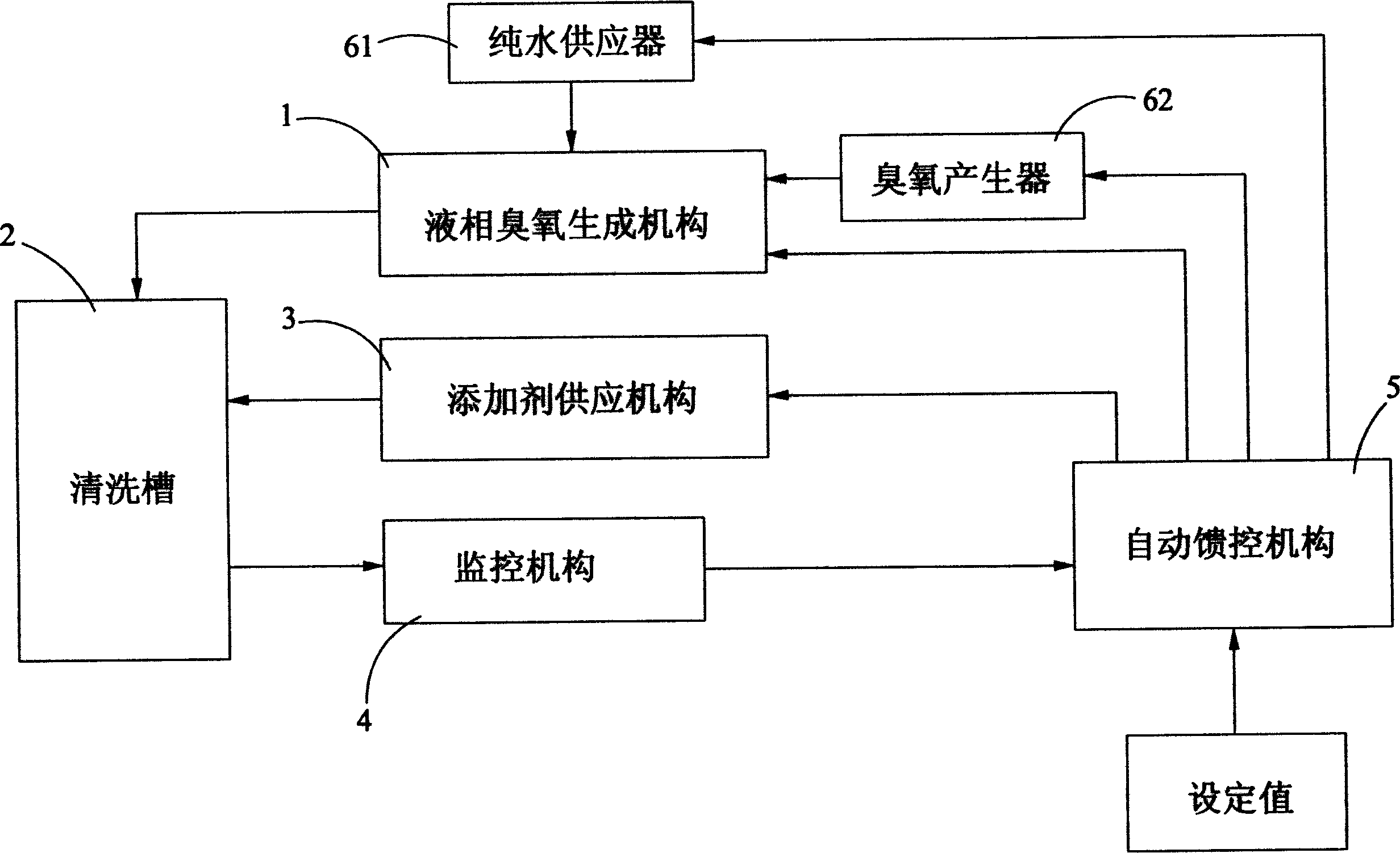

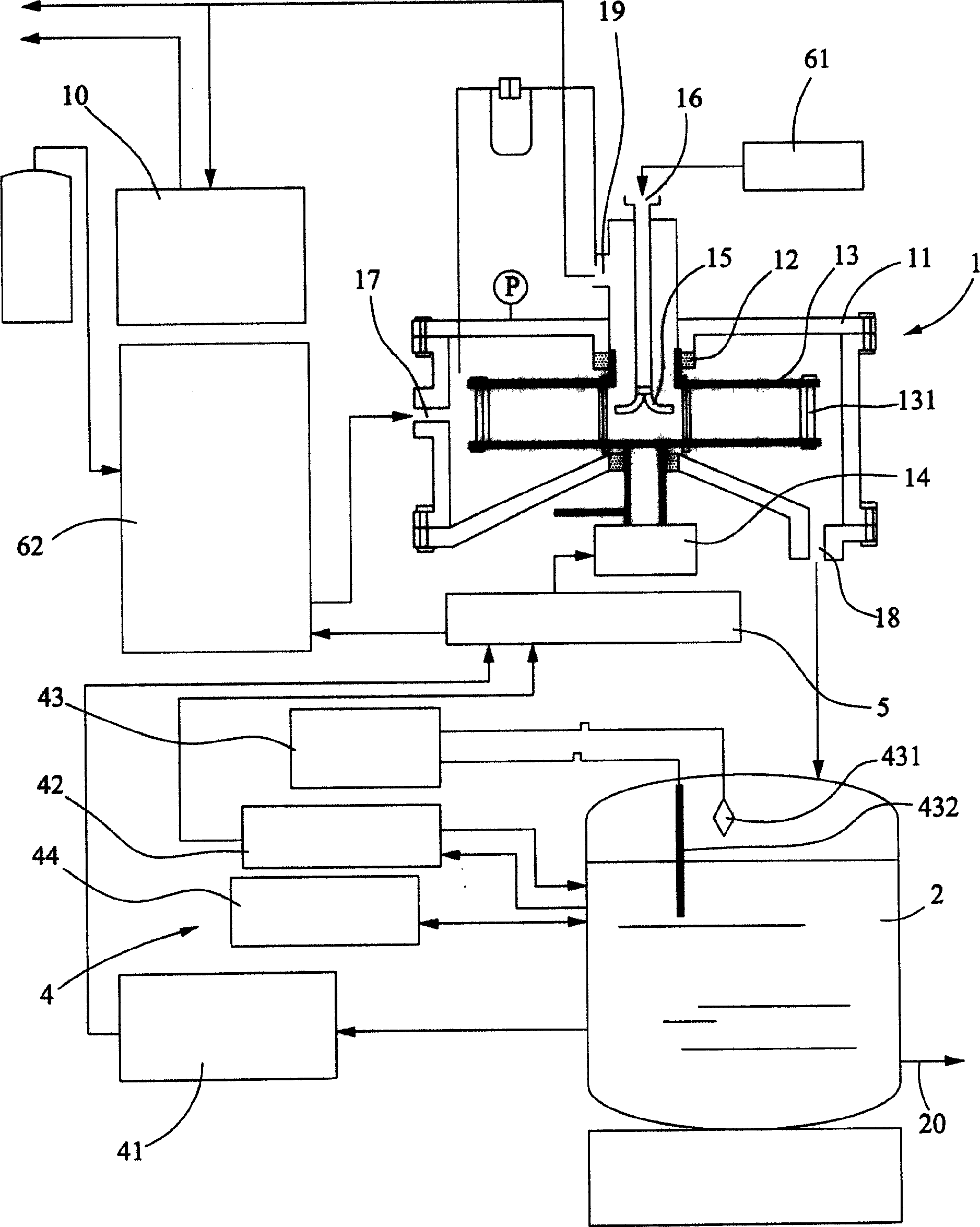

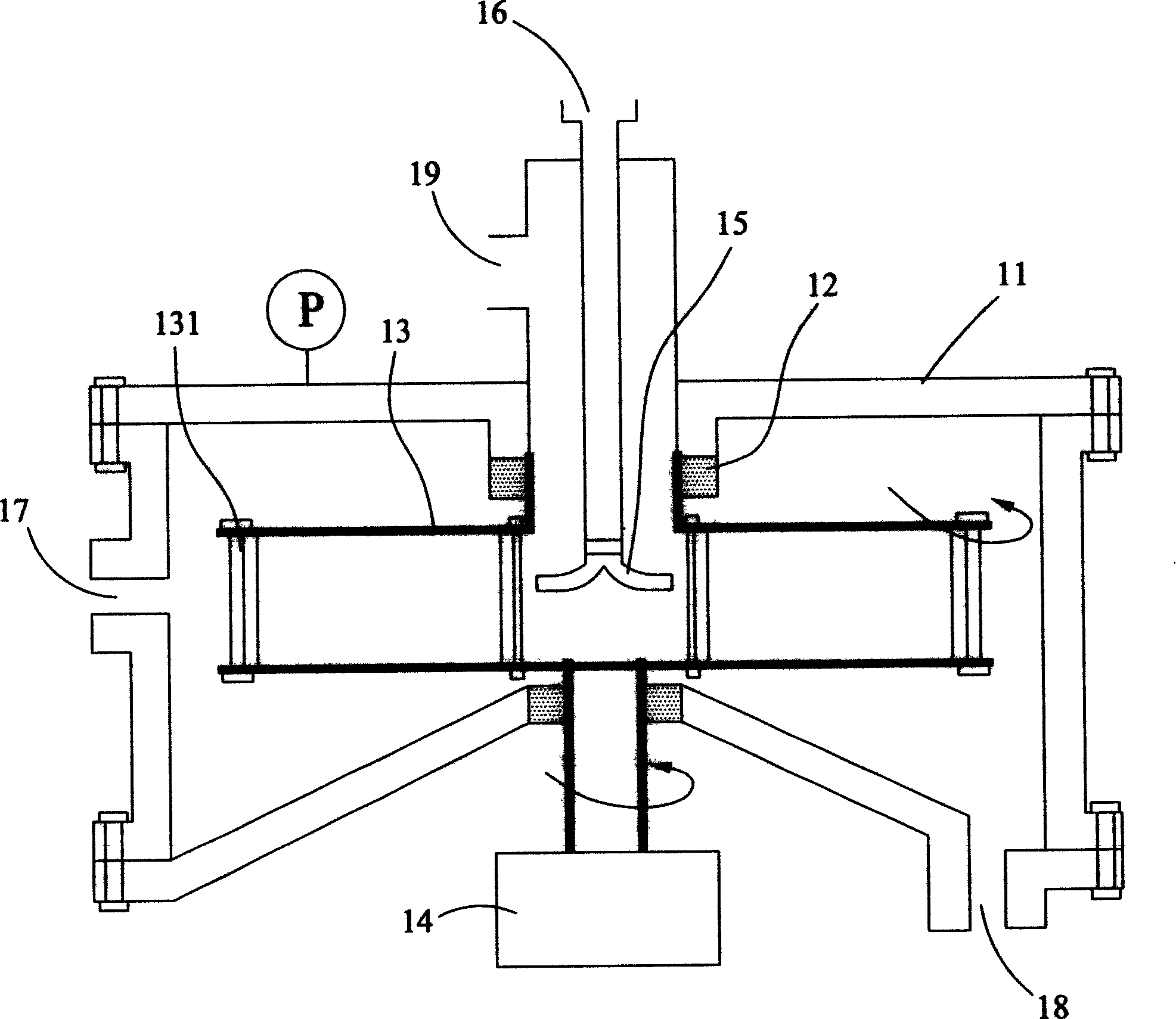

[0076] The present invention relates to a production process utilizing high-concentration and large-flow ozone water to form liquid-phase ozone water and provide it as a cleaning solution, and perform wafer cleaning operations in a storage tank or a cleaning tank. The dynamic analysis technology of parameters such as solution concentration and conditions can grasp the monitoring of various parameters in the cleaning tank such as ozone and additive concentration, pH value and water temperature and other environmental conditions at any time, and use the obtained parameters to generate feedback control and automatically adjust various Parameters, so as to maintain the best concentration distribution effect of the cleaning tank, and perform continuous and rapid cleaning of a large number of wafers while maintaining the effective cleaning capacity of the wafer surface.

[0077] The preferred embodiment of the present invention suitably discloses the main technical content of the met...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap