Multi-magnetic pole DC motor

A DC motor, multi-pole technology, applied in the direction of DC commutator, electrical components, electromechanical devices, etc., can solve the problems of current loss, large current, large energy consumption of DC motor, avoid mutual cancellation, increase density, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

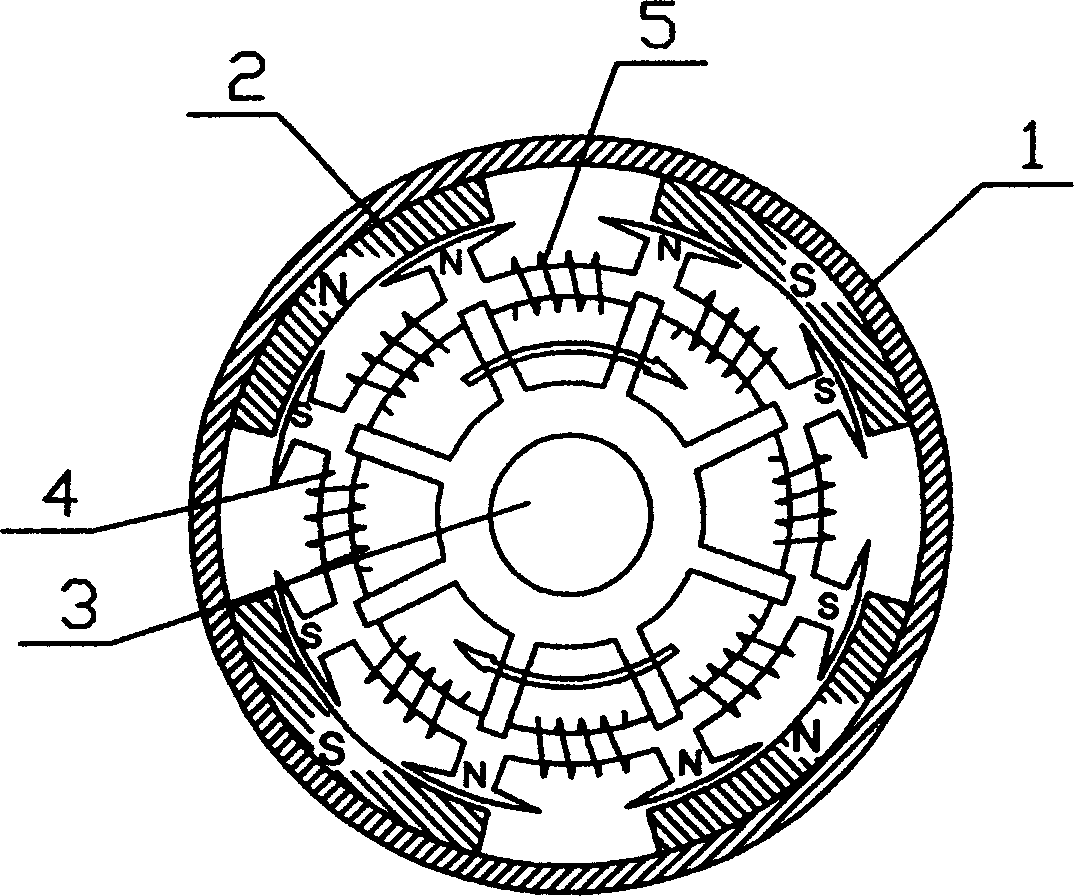

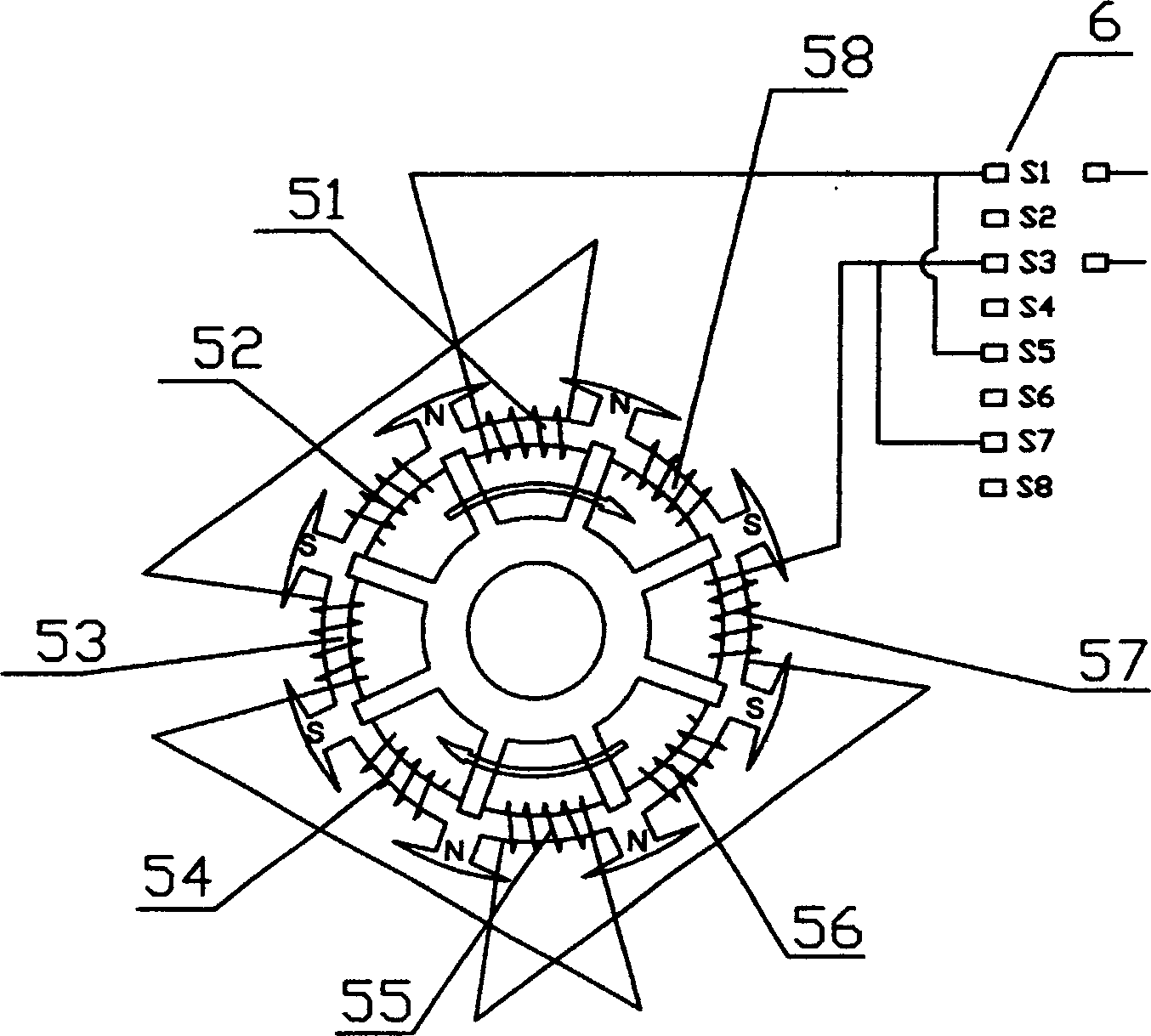

[0008] as attached figure 1 As shown, the multi-pole DC motor includes a casing 1, a stator 2 installed in the casing 1, a rotor core 4 installed on the rotating shaft 3, and an armature winding 5 wound on the rotor core 4 to generate magnetic flux , the converter 6 installed on the above-mentioned rotating shaft 3 and supplying power to the above-mentioned armature winding 5, the stator 2 is provided with two pairs of magnetic poles, and the number of coils of the armature winding 5 wound on the rotor core 4 There are 8 coils, and the intervals are divided into two working coil groups, the adjacent coils of each working coil group generate the same adjacent magnetic field poles, and the coils of each working coil group are connected in series with the The converter 6 is electrically connected.

[0009] The rotor of the present invention is different from the past. The number of slots of the rotor armature can be set according to the needs. The rotor has three major component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com