Base plate conveying device

A technology for conveying devices and substrates, which is applied in the direction of transportation and packaging, conveyor objects, program control manipulators, etc. It can solve the problem that the distance between a pair of arms 26 cannot be changed, and achieve the effect of simple structure and easy change of production arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

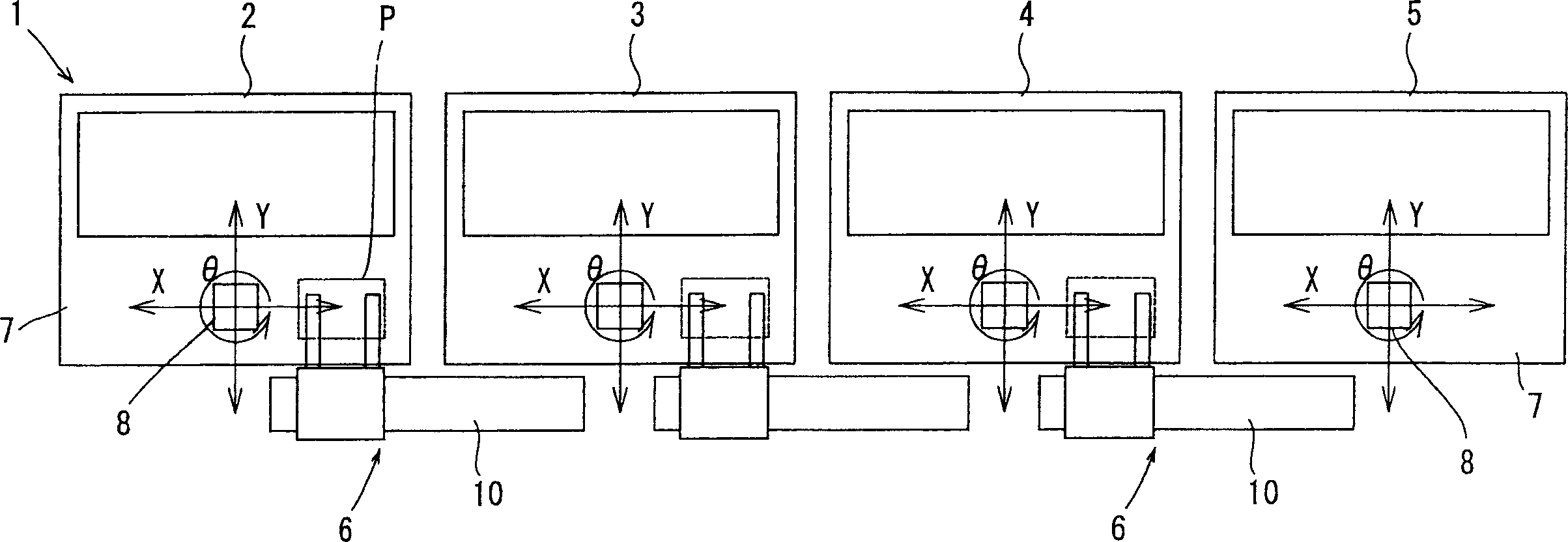

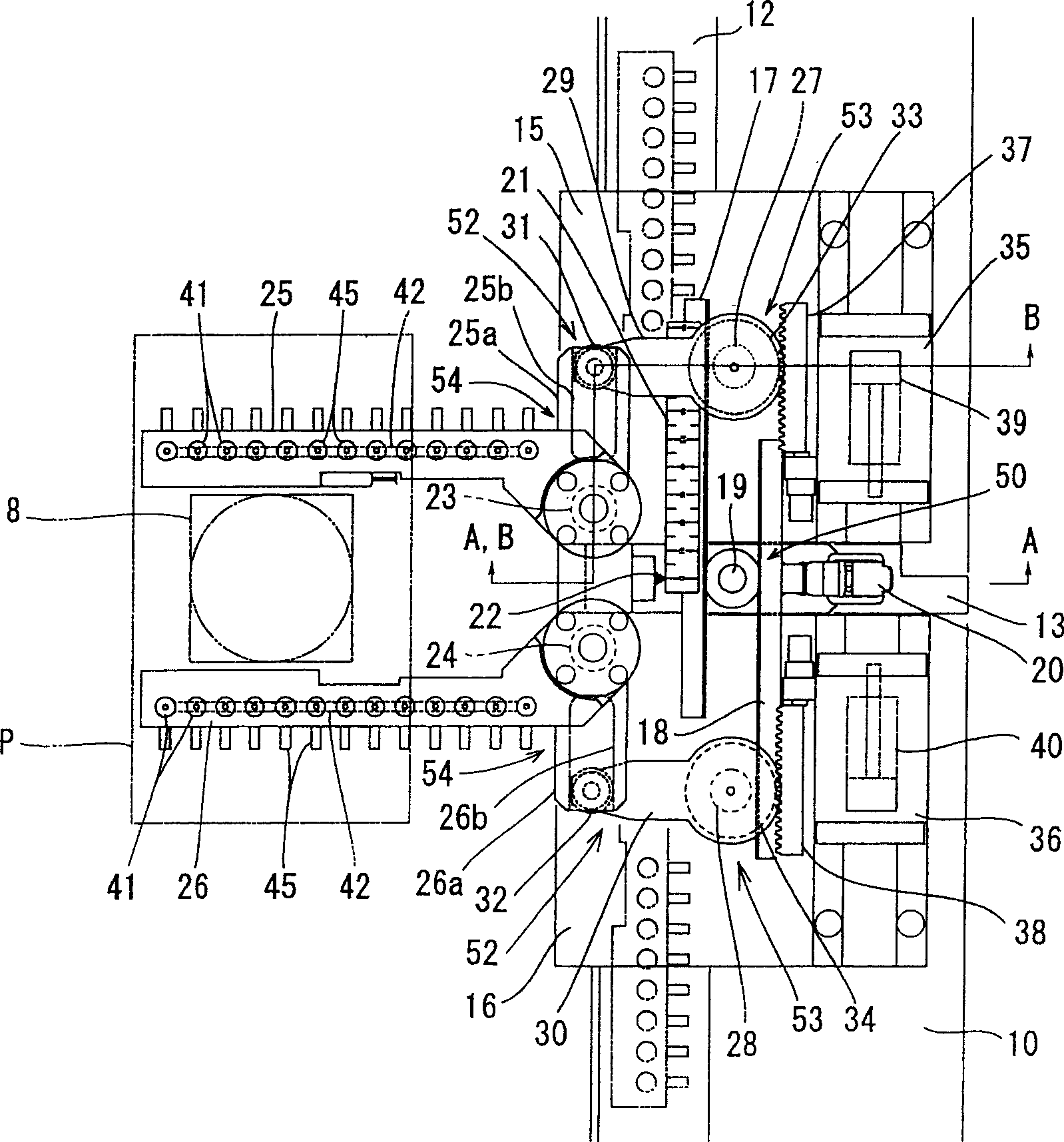

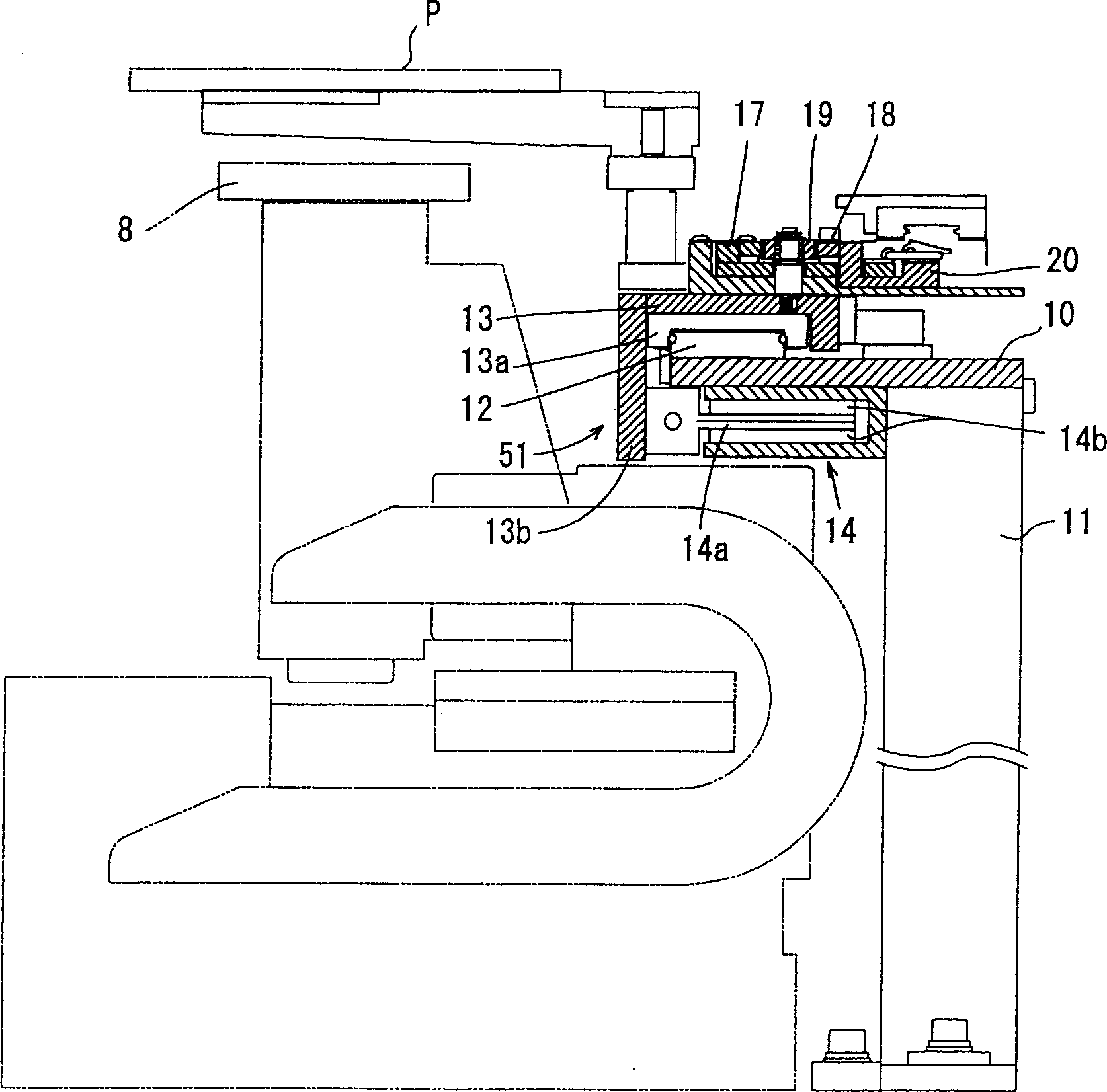

[0020] Next, the substrate transfer device of the present invention will be described with reference to the drawings. exist figure 1 Among them, 1 is a production line for mounting chips or thin films on a liquid crystal display panel (hereinafter referred to as a substrate) to produce a liquid crystal display device, which is composed of a cleaning device 2 for cleaning the terminals of the substrate P, pasting an anisotropic conductive film (ACF) The ACF attaching device 3 attached to the substrate P, the loading device 4 for mounting the printed chip or the film (FPC) of the circuit, and the crimping device 5 for pressing the loaded chip or FPC to be bonded to the substrate P are composed. The substrates are sequentially transported from the cleaning device 2 to the pressure-bonding device 5 , and the substrate transport device 6 is arranged across the adjacent devices. Each of the devices 2 to 5 is mounted with a stage 8 on the base 7, and each stage 8 moves linearly alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com