Sea water desalting plant processed deep in sea

A seawater, deep-seated technology, applied in osmosis/dialysis water/sewage treatment, general water supply saving, etc., can solve problems such as energy consumption, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

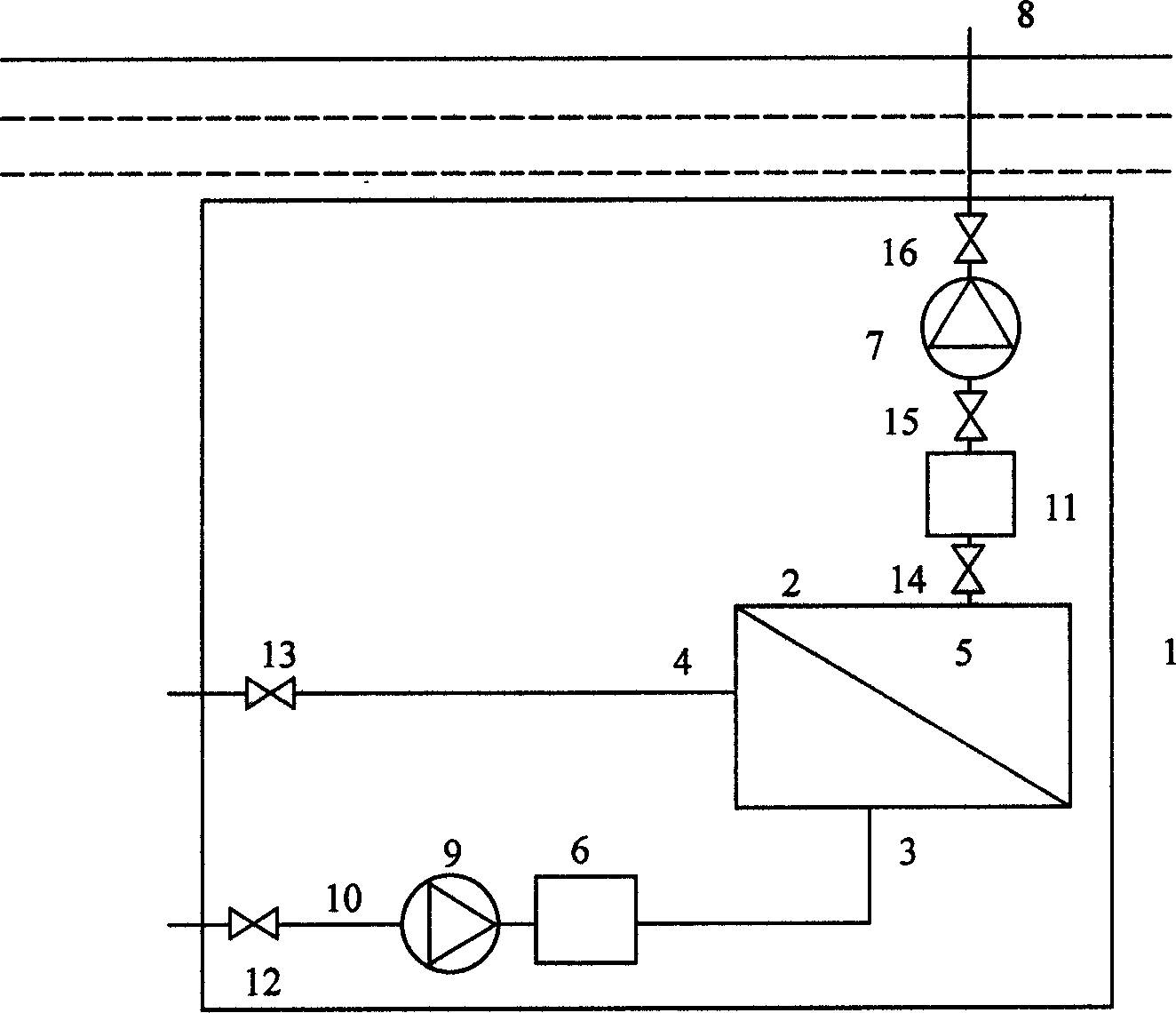

[0013] like figure 1 shown

[0014] The pressure-resistant sealing device [1] is placed several hundred meters below the sea surface [8]. The pressure-resistant sealing device [1] is equipped with reverse osmosis equipment [2], and a high-pressure side interface [3] is connected to the pre-treatment device [6]. The pre-treatment device [6] includes an ultrafiltration device and a security filter. The other end of the device is connected to the outlet of the circulating pump [9], and the inlet [10] of the circulating pump extends out of the pressure-resistant sealing device and is sealed and connected with the pressure-resistant sealing device. Another interface [4] on the high pressure side of the reverse osmosis device [2] extends out of the pressure-resistant sealing device and is hermetically connected with the pressure-resistant sealing device [1]. The permeate outlet [5] of the reverse osmosis device [2] is connected to the water storage tank [12], the water storage tan...

Embodiment 2

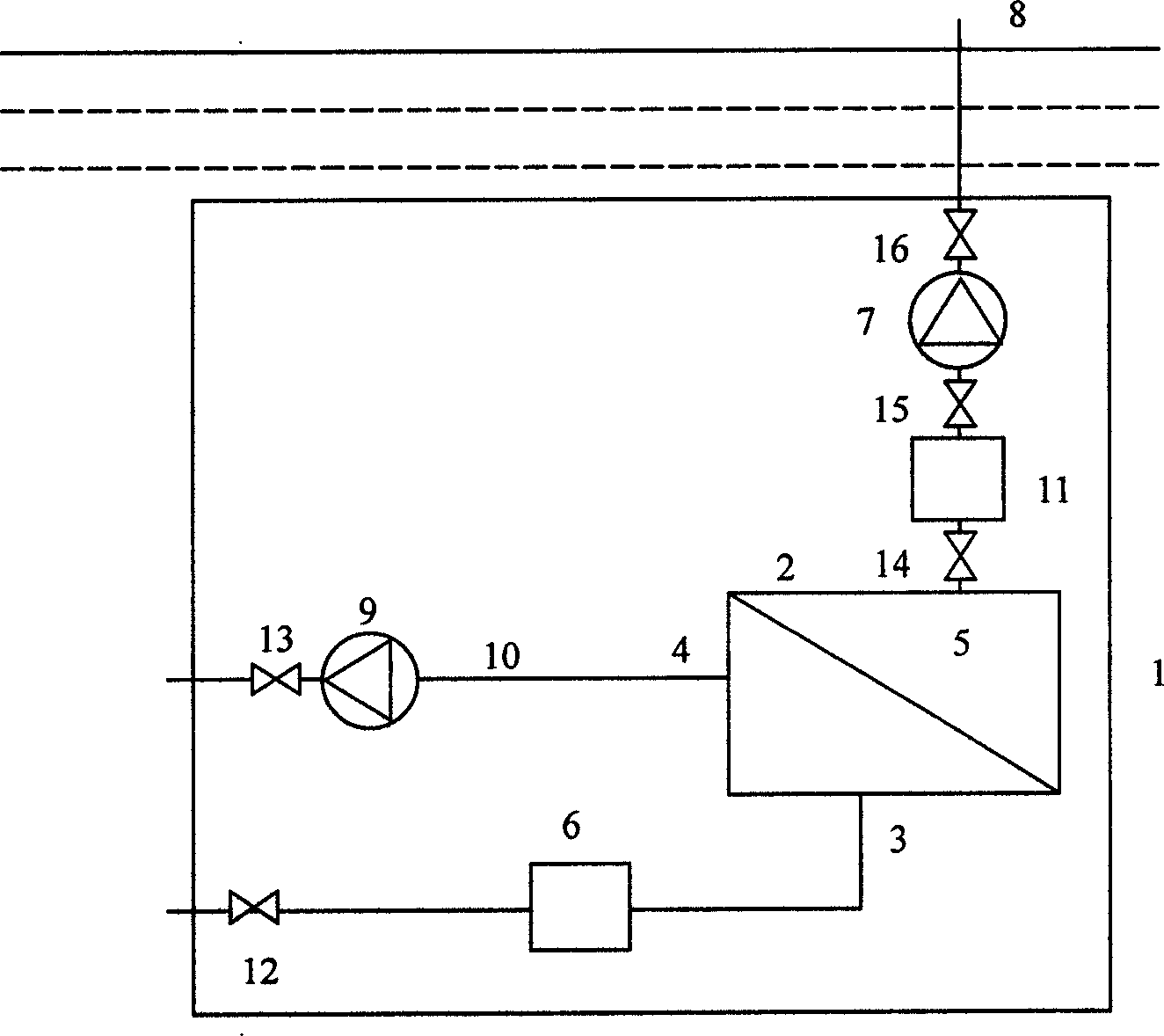

[0016] like figure 2 shown.

[0017] Connect the inlet [10] of the seawater circulation pump to the outlet [4] of the reverse osmosis device [2], and the outlet of the seawater circulation pump stretches out of the pressure-resistant sealing device and is hermetically connected with the pressure-resistant sealing device [1]. Valves can be added between each component. Open all valves and start the seawater circulation pump [9]. Seawater flows through the valve [12], the pretreatment device [6], the inlet [3] of the reverse osmosis device [2], flows through the reverse osmosis membrane, and is fed by the outlet [4] of the reverse osmosis device [2], the seawater circulation pump [9] ], valve [13] flow out pressure-resistant sealing device [1], and the fresh water that sees through film is through valve [14], water storage tank [11], valve [15], and is sent out sea surface by delivery pump [7].

Embodiment 3

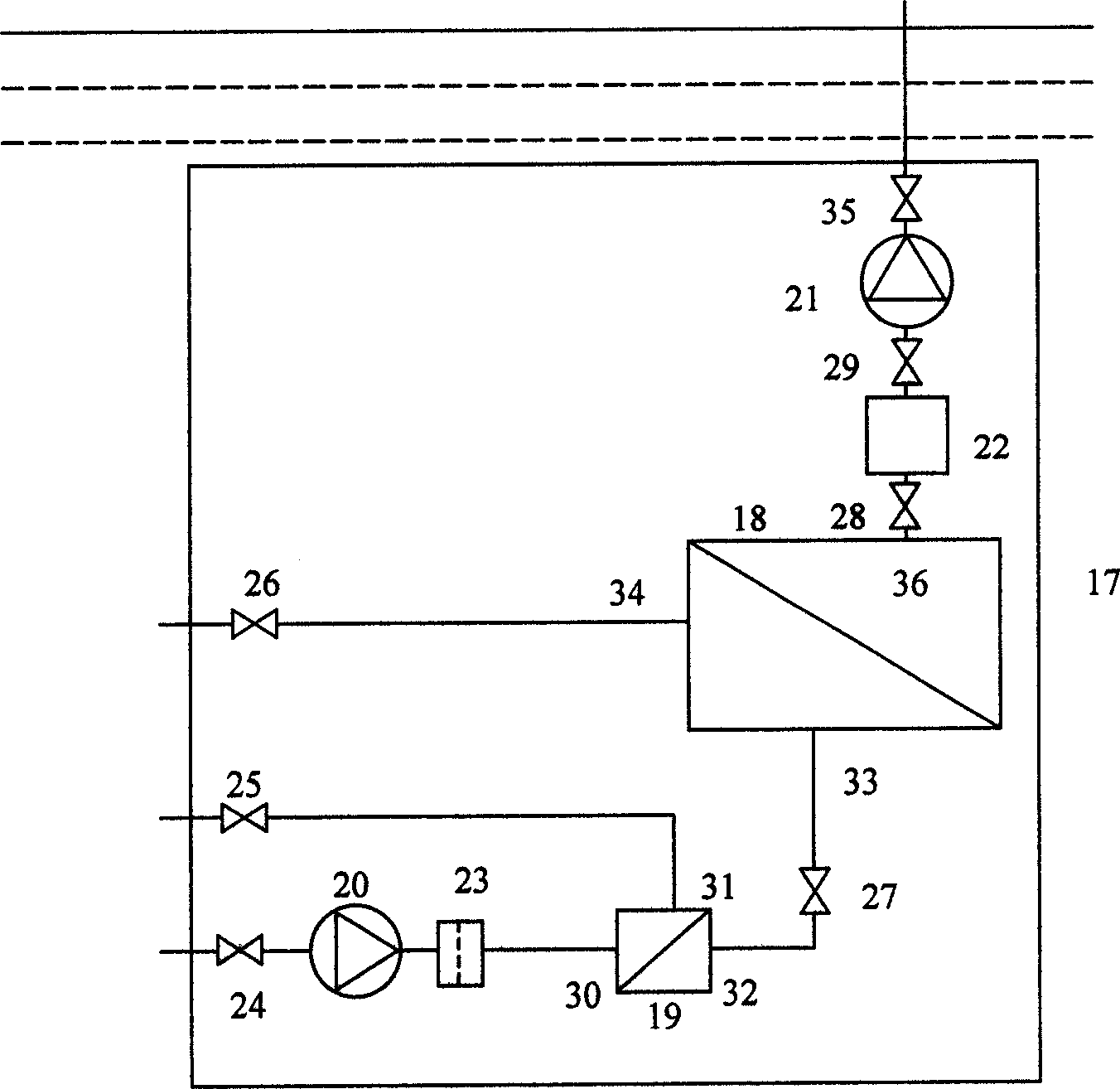

[0019] like image 3 shown

[0020] The pressure-resistant sealing device [17] is equipped with reverse osmosis equipment [18], ultrafiltration equipment [19], seawater circulation pump [20], fresh water output pump [21] and so on. The inlet of the seawater circulating pump [20] is connected to the valve [24], and the other end of the valve [24] is connected to the pipe to stretch out the pressure-resistant sealing device [17], and is sealingly connected with the pressure-resistant sealing device [17]. The outlet of the seawater circulation pump [20] is connected to the security filter [23], and the other end of the security filter [23] is connected to a raw liquid circulation port [30] of the ultrafiltration equipment [19], and the other end of the ultrafiltration equipment [19] Stock solution flow port [31] connects valve [25], and the other end of valve [25] connects pipe and stretches out pressure-resistant airtight container [17] and is sealed with pressure-resistant air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com