Magnetic circuits of electrical machines

A technology of magnetic flux and stator, applied in the direction of magnetic circuit, synchronous generator, magnetic circuit static parts, etc., can solve the problems of increasing thermal characteristics, increasing power supply capacity, limiting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

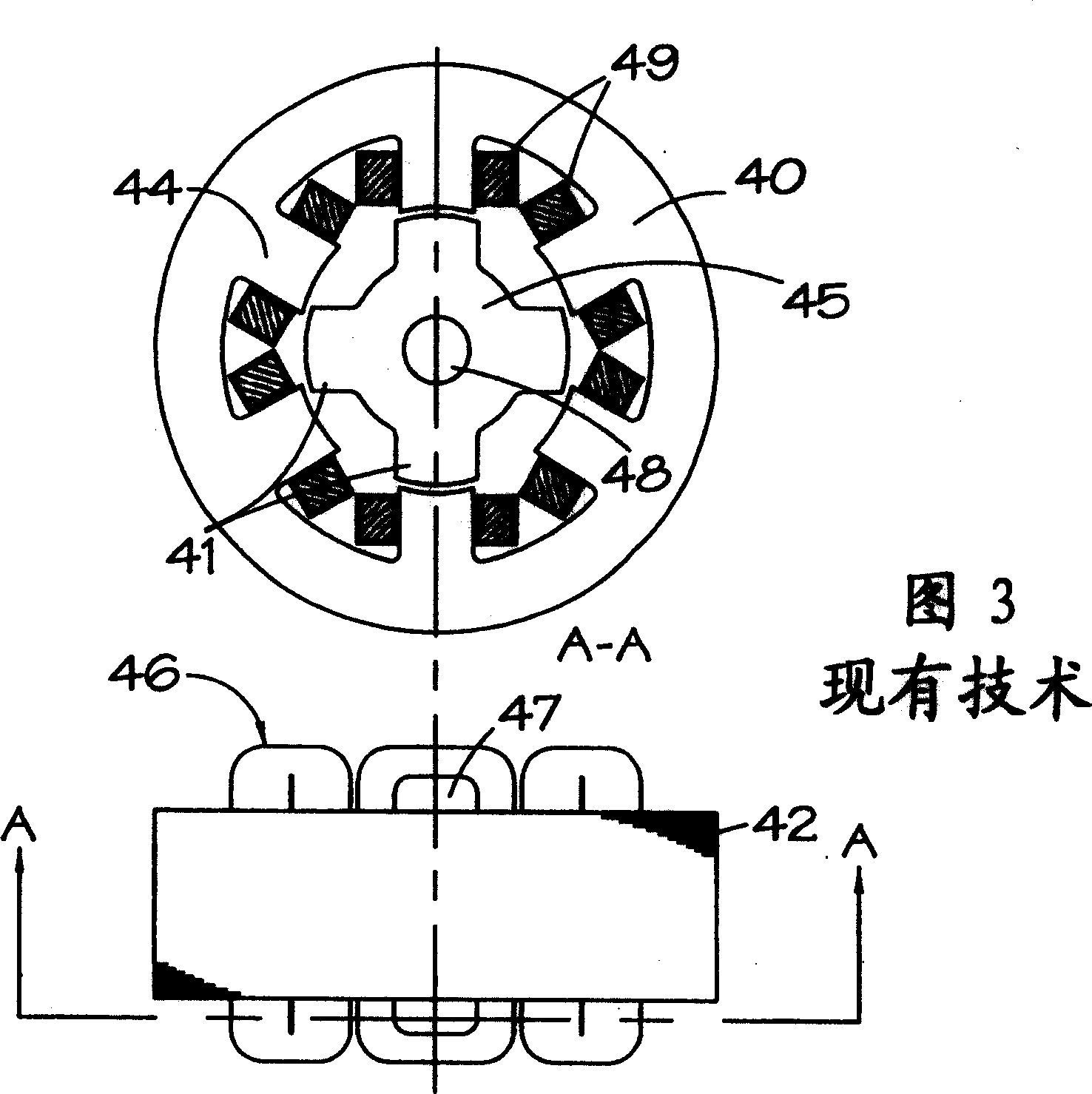

[0038] Figure 5 Stator flux plates are shown which are shaped to cooperate with the ends of stator core segments which, for example as shown in FIG. pole. The solid flux plate 50 has an annular portion 51 whose inner and outer diameters correspond to the back iron portion of the stator laminations. A plurality of teeth 52 project radially inwardly from the annular portion. Each tooth 52 is sized such that the tooth matches the shape of the stator pole 44, or the tooth is located slightly inward of the profile of the pole. The number of teeth on the flux plate is the same as the number of poles of the stator. The cross-sectional view of the flux plate shows that it has flat sides 53 adjacent to the end faces of the magnetizable lamination segments making up the stator core 42 . The teeth on the opposite side 54 of the flux plate are contoured to match the contour of the gap 47 (see FIG. 3 ) formed between the coil protrusion 46 and the extreme end. Figure 5 The illustrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com