Board-level EMI shield with enhanced thermal dissipation

A board-level, substrate technology, applied in the field of board-level electromagnetic interference shielding, can solve problems such as increasing weight, not allowing mutual shielding, and consuming valuable PCB space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

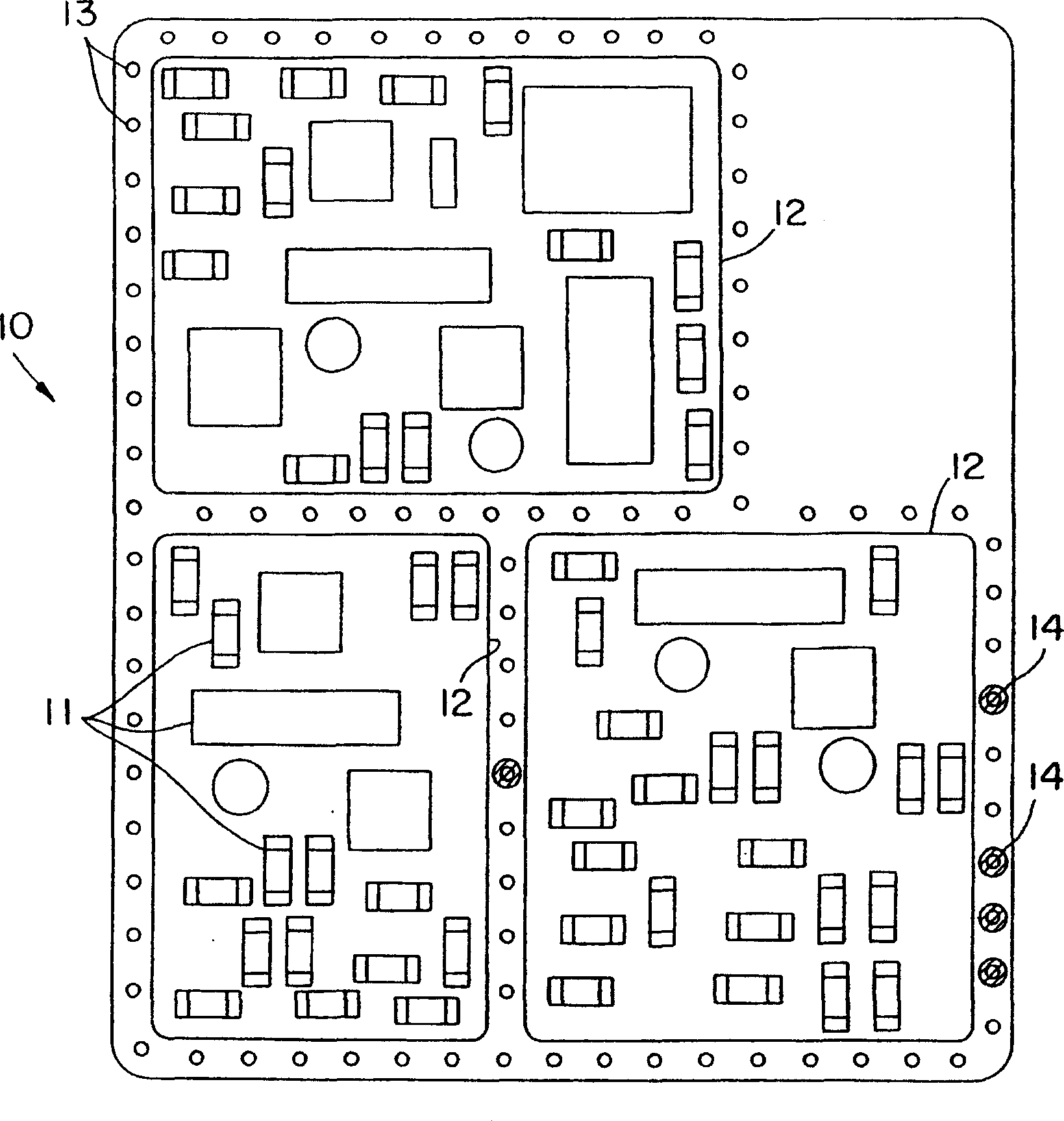

[0022] Referring now to the drawings, the present invention provides board level EMI shielding that enhances heat dissipation from shielded components. figure 1 is a plan view of a PCB (10) according to an embodiment of the present invention. A PCB (10) is a substrate having a plurality of electrical components (11) grouped together in an area (12). Surrounding the area (12) are a plurality of ground trace pads (13). Disposed on each ground track pad (13) is a conductive fastening unit (14). The conductive fastening unit (14) is mechanically and electrically coupled to the ground trace pad (13), for example by using solder. For ease of illustration, only some ground trace pads (13) are shown to have conductive fastening units (14) disposed thereon, but preferably, all ground trace pads (13) have conductive fastening units (14) disposed thereon. permanent fastening unit (14). A plurality of discrete conductive fastening units (14) are arranged on the PCB (10) in a pattern s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com