Magnetic condensing system for cryogenic engines

A low-temperature thermal and paramagnetic technology, applied in the direction of machines/engines, the magnetism of inorganic materials, and the operating mode of machines, can solve the problems of expensive superconducting electromagnetic coils and low power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

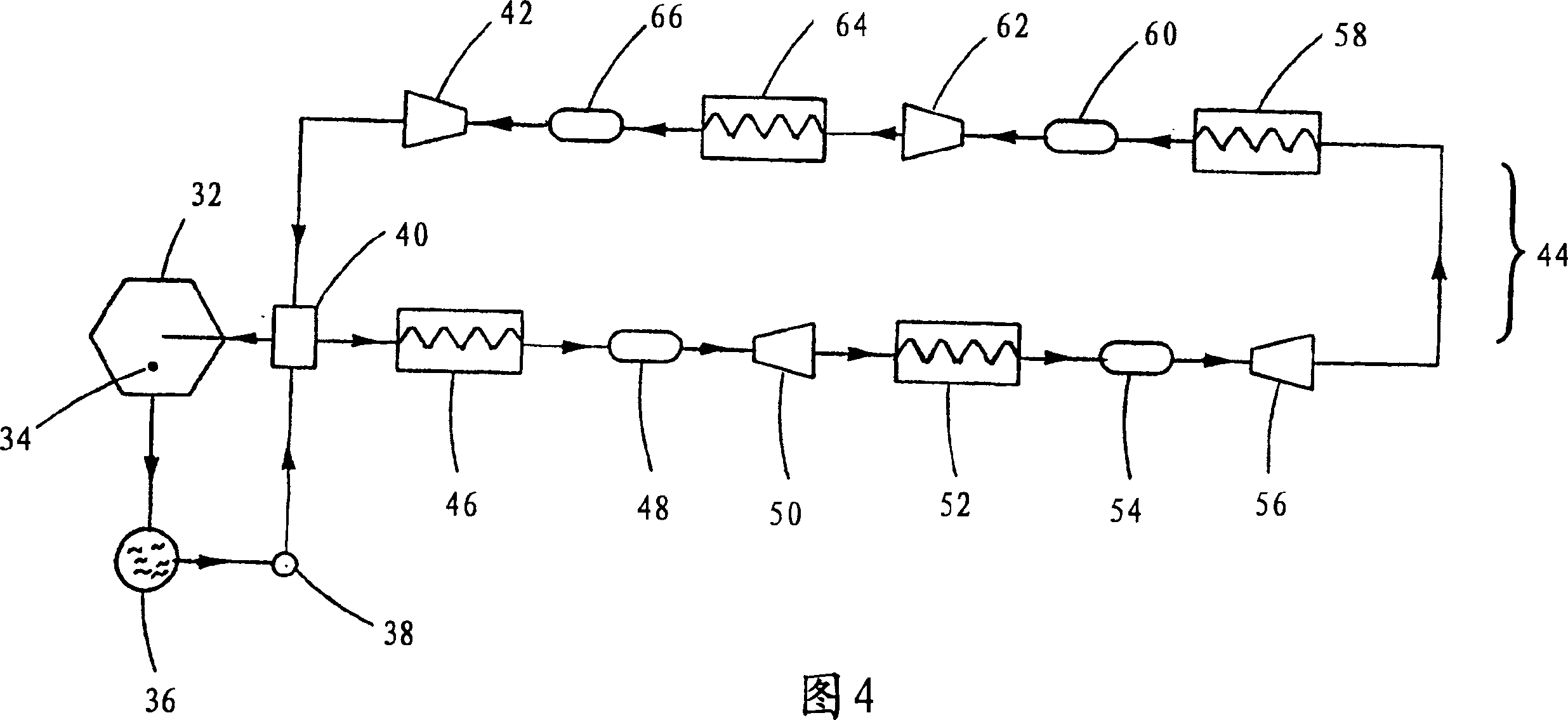

[0021] Description of preferred embodiments

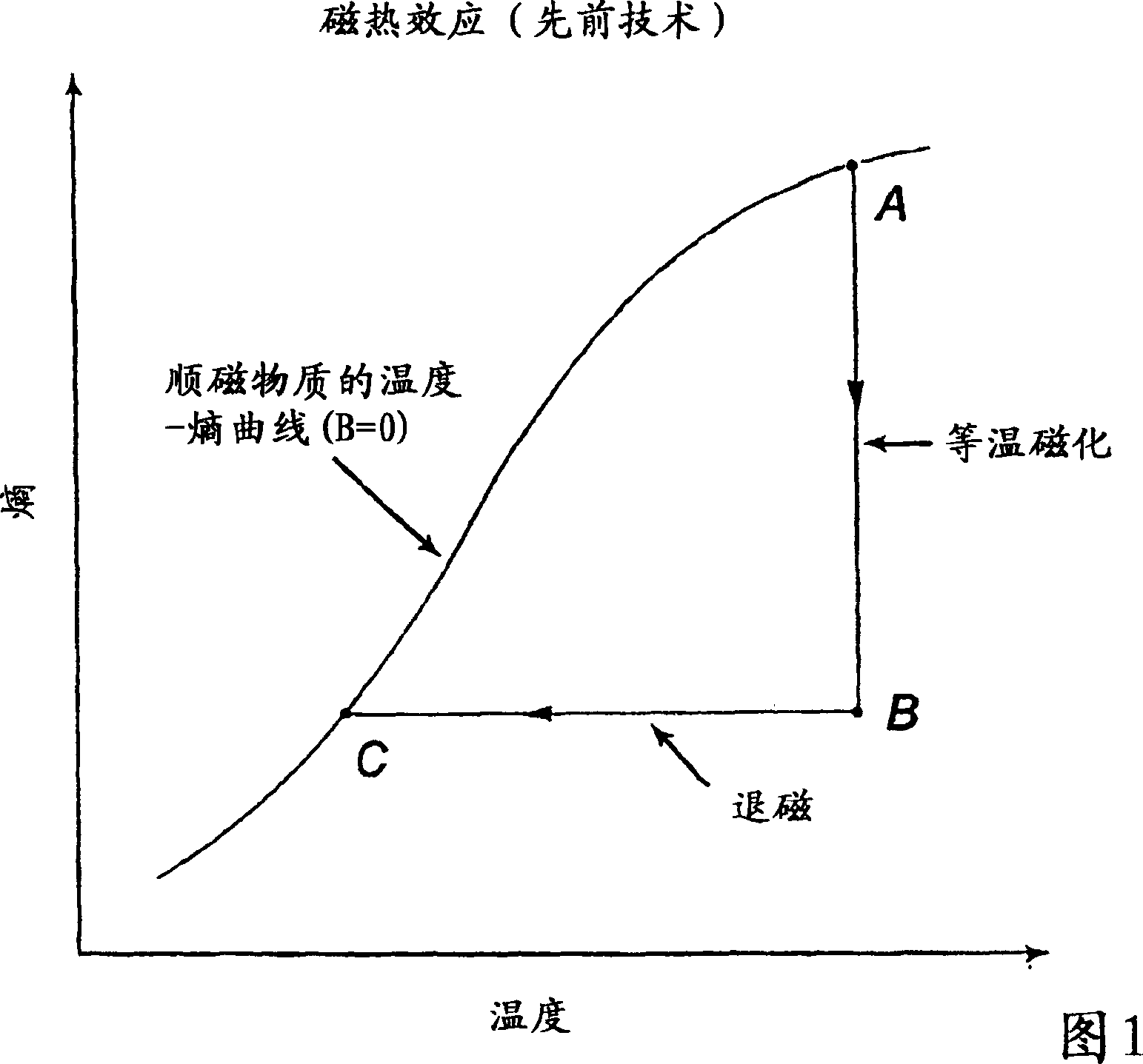

[0022] The basic physical principle utilized in the design of the magnetic condensation system described here is the principle of adiabatic demagnetization, also known as "magnetic cooling" or "magnetocaloric effect". Therefore, before describing the detailed design and operating characteristics of the magnetic condensation system, it is instructive to review the basic operating principles of adiabatic demagnetization and how these principles are applied to prior art magnetic refrigeration systems. This will provide a basic understanding of the unique working characteristics of the present invention, which can be easily distinguished from the prior art.

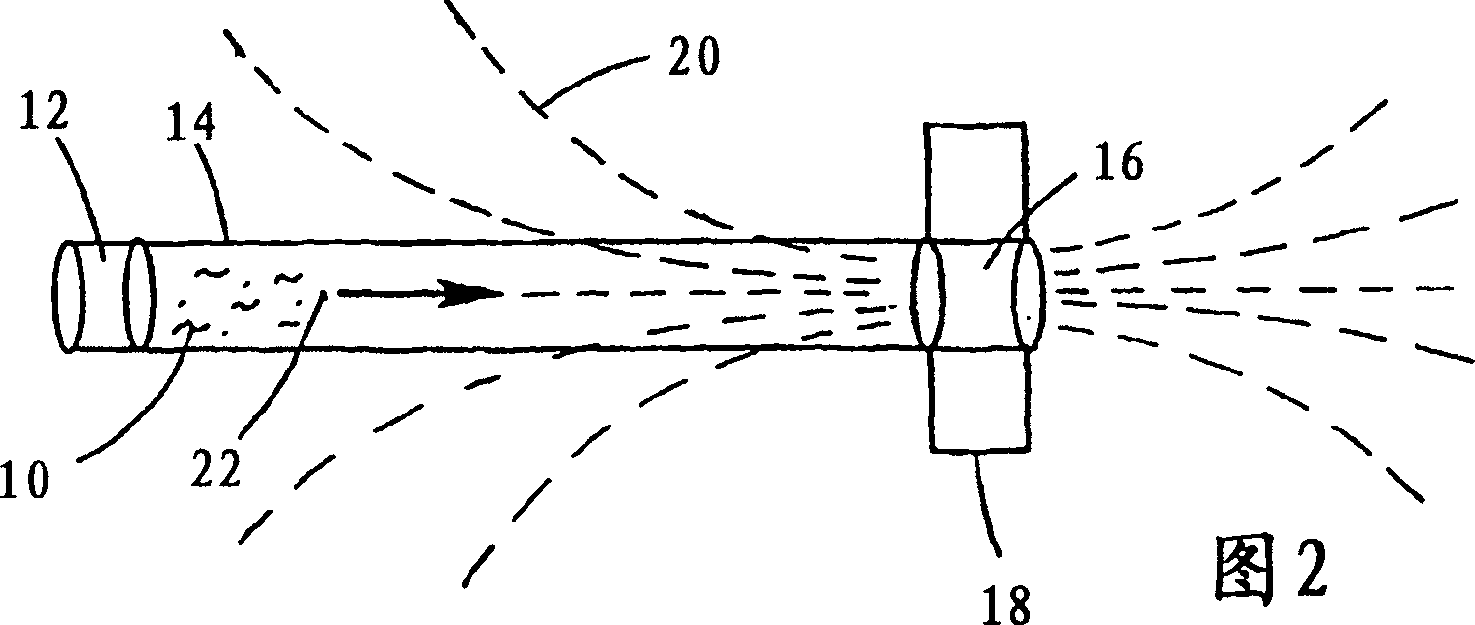

[0023] In making this comparison, it is important to point out and emphasize at the outset that all prior art "magnetic refrigeration systems" utilizing the magnetic cooling principle of adiabatic demagnetization employ paramagnetic substances in solid or powder form. In the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com