Energy collection type wind energy power station by pipe conveying

An energy-collecting, power station technology, applied in the field of wind-collecting ultra-large-capacity wind power generation devices, can solve the problems of high maintenance costs, high equipment investment, high power costs, etc., to achieve less energy consumption, more power, and reduced wind energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

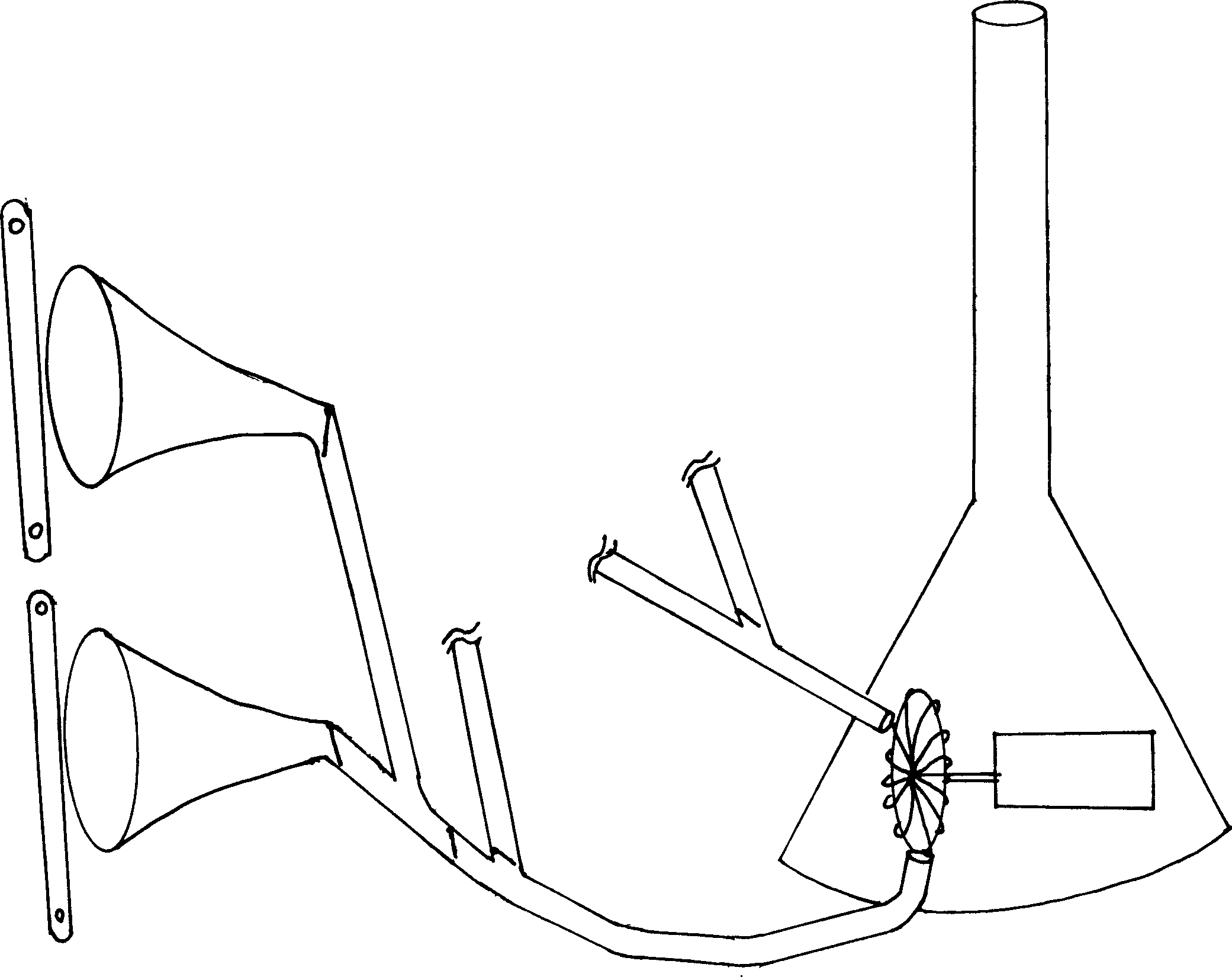

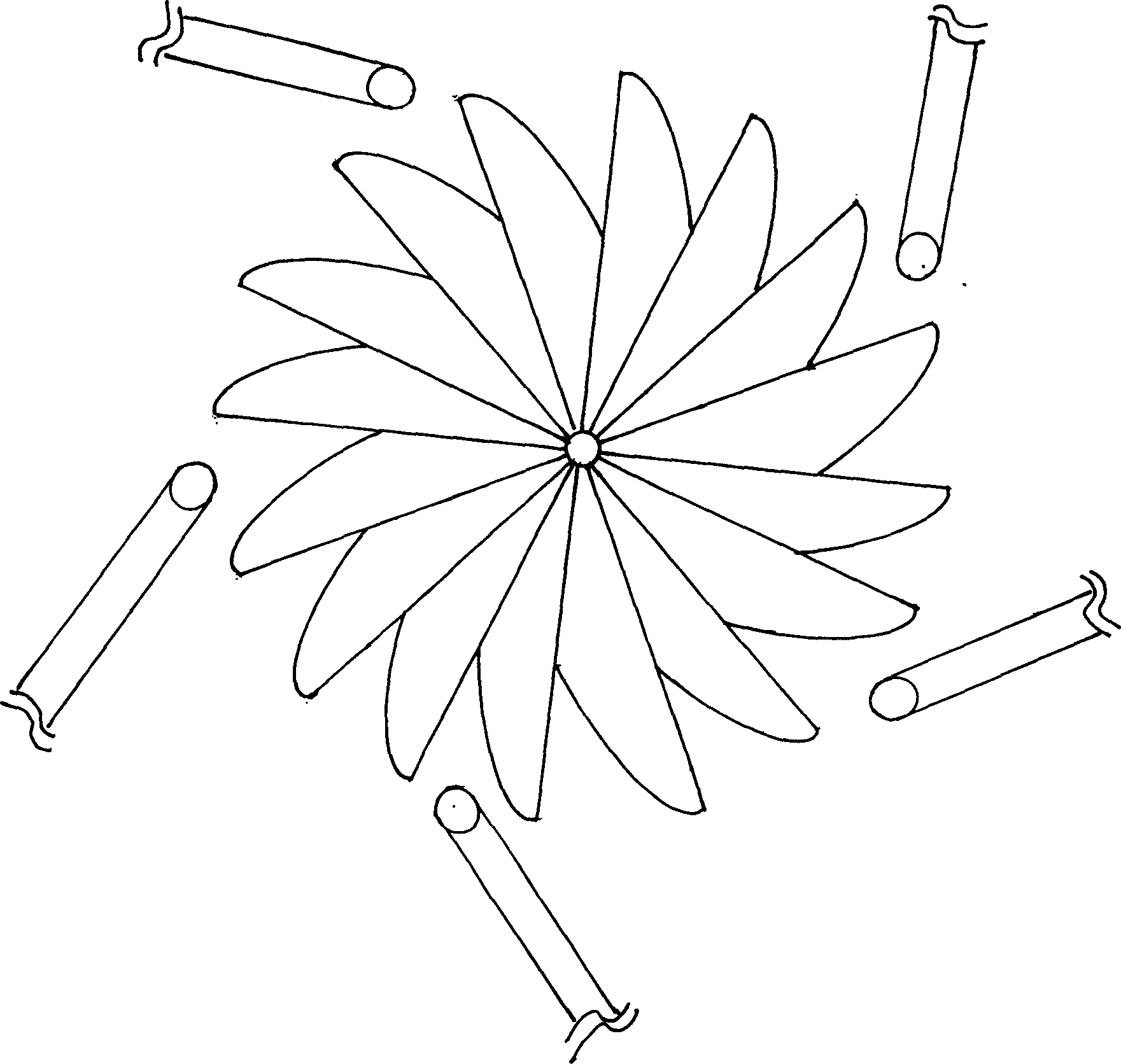

[0010] Such as figure 1 As shown, the wind energy power station uses a plurality of bell mouths 1 or forms a bell mouth array to collect wind energy. The bell mouths are installed in different directions in different places, and each bell mouth is connected to the air guide pipe 2 respectively. In machine room 3, several branch air ducts in the same direction or at the same place can also be aggregated into a total air duct 2′, which is then connected to the machine room of generator 5, and wind energy is combined into more powerful energy. Arranged according to the direction in which the generator impeller 4 rotates ( figure 2 ), and aligned with the generator impeller, the impeller is connected with the generator shaft 6, when the wind energy collected by the bell mouth from all directions is transmitted to the generator set through the air duct and acts on the impeller, the generator impeller rotates, and the impeller drives the engine shaft Spin, the generator works. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com