Vibration damper with controllable stiffness and damping

A shock absorber and damping technology, which is applied in the field of mechanical shock absorbers, can solve the problems of increasing the difficulty of packaging, complex structure of shock absorbers, easy settlement of magnetorheological fluid, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

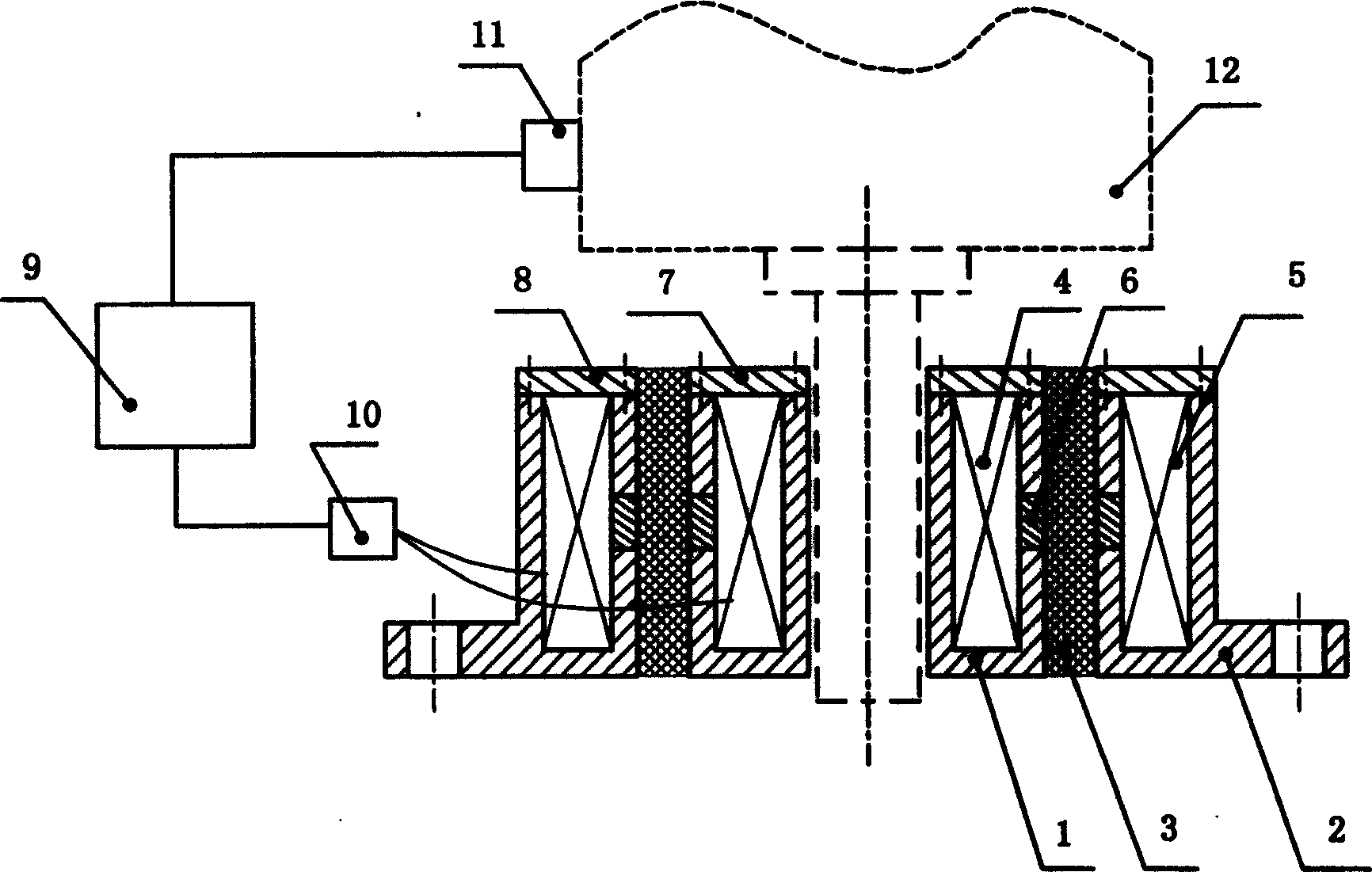

[0019] Such as figure 1 As shown, the vibration damping system involved in the present invention includes an execution part (that is, a shock absorber) and a control part. Wherein the shock absorber is composed of an inner sleeve 1, an outer sleeve 2, a magnetorheological elastomer 3, an inner coil winding 4, an outer coil winding 5, and a magnetic resistance ring 6. The magnetorheological elastomer 3 is located between the inner sleeve 1 and the outer sleeve 2, and is fixedly connected to the inner sleeve 1 and the outer sleeve 2 at the same time. The inner sleeve 1 is a straight cylinder with a through hole in the center and a cavity inside, that is, the inner sleeve is in the shape of a ring (it can also be a suitable shape such as a rectangular ring, an elliptical ring, etc., to adapt to the shape of the vibration reduction object. or installation requirements, etc.). The cavity in the inner sleeve can be formed by a variety of processing methods, such as milling a circu...

Embodiment 2

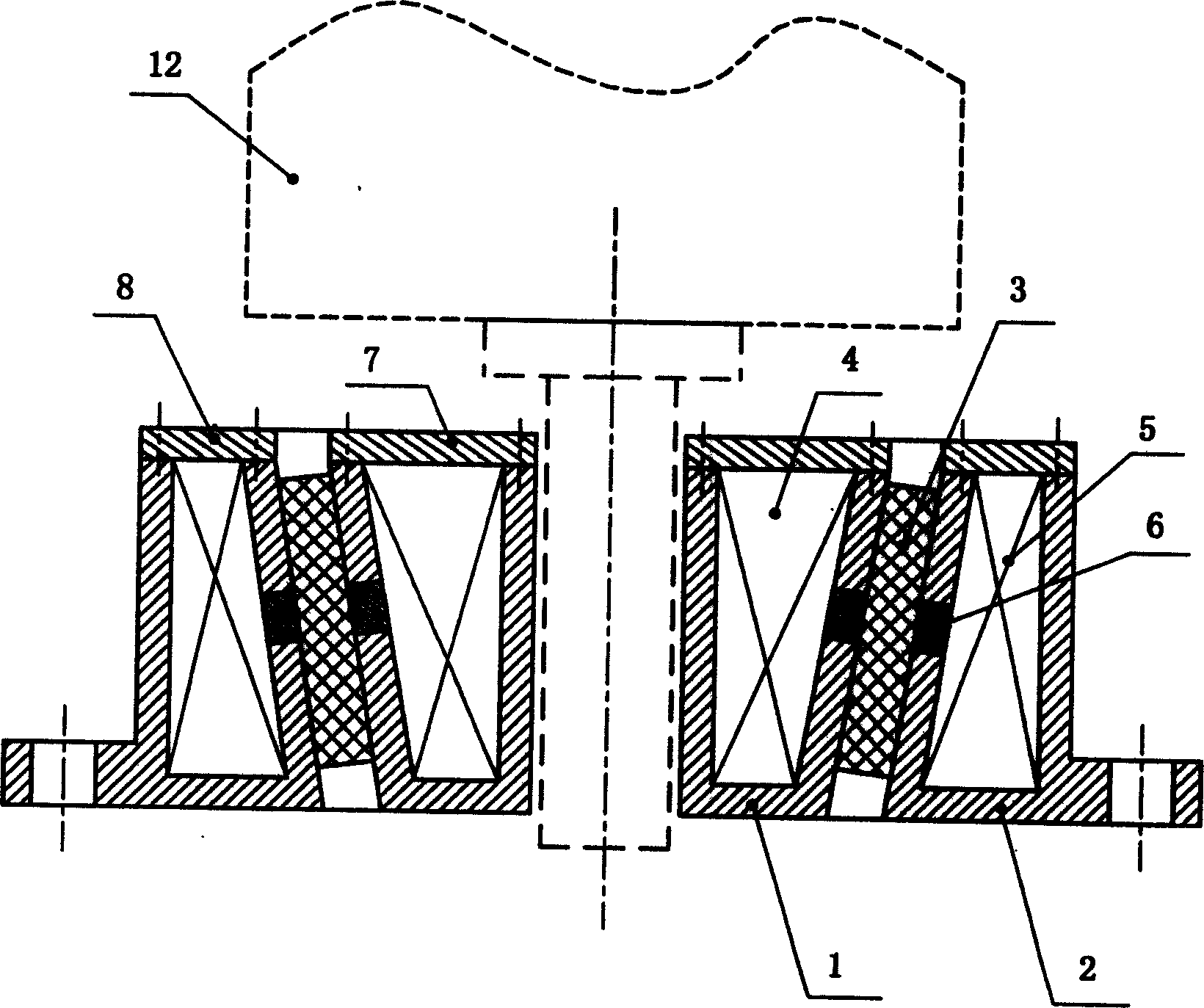

[0029] Such as figure 2 As shown, in the shock absorber, the inner casing 1 and the outer casing 2 can also be cones, and the magnetorheological elastomer 3 between the inner and outer casings can also be a cone. The magnetorheological elastomer is vulcanized with the outer side of the inner sleeve and the inner side of the outer sleeve. Coil windings are respectively arranged in the inner and outer cavities. When the combination between the inner and outer coats and the elastic body is firm enough, the elastic body does not have to be of the same height as the inner and outer coats. With the cone, the elastic body is not only sheared but also squeezed. Adjusting the taper of the cone can adjust the degree of shearing and extrusion of the elastic body. In this way, not only the vibration excitation along the direction of the central axis can be damped, but also the vibration excitation perpendicular to the central axis can be damped to a certain extent, thus possessing the ...

Embodiment 3

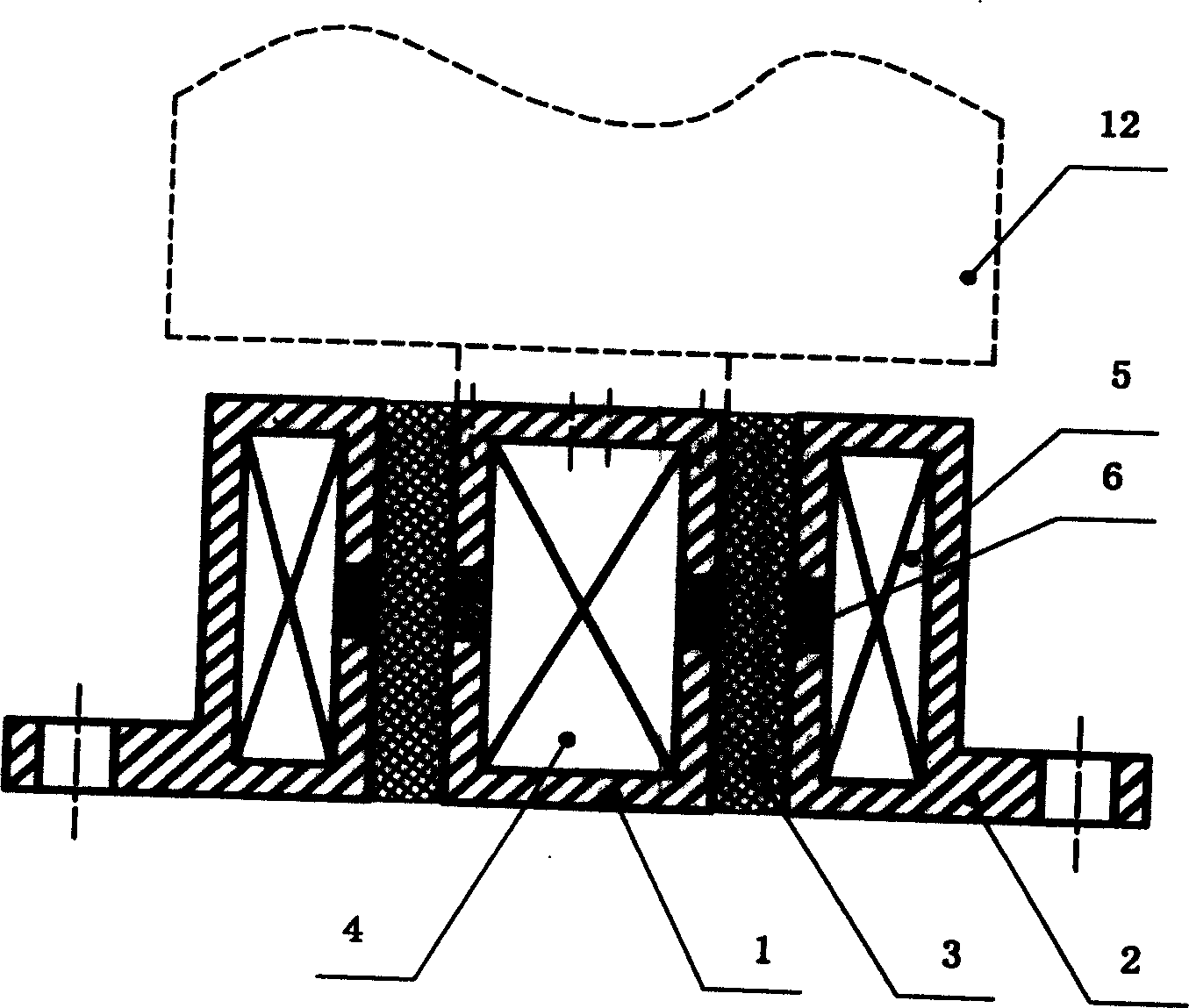

[0031] Such as image 3 As shown, in the shock absorber, the inner sleeve 1 can also be a cylinder with no through hole in the center and a cavity inside, that is, the inner sleeve is columnar (it can also be a suitable shape such as a rectangular column, an elliptical column, etc., to adapt to The shape of the damping object or installation requirements, etc.). Other structures can be similar to Embodiment 1 or Embodiment 2, that is, the inner casing 1, the outer casing 2, and the magnetorheological elastomer 3 are all in the shape of a straight cylinder or a cone. The magnetorheological elastomer is vulcanized with the outer side of the inner sleeve and the inner side of the outer sleeve. When the combination between the inner and outer coats and the elastic body is firm enough, the elastic body does not have to be of the same height as the inner and outer coats. There are inner and outer coil windings respectively in the cavities of the inner and outer jackets. The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com