Stiffness and damping changing passive control device with an electrorheological composite laminated rubber bearer

A technology of composite lamination and rubber bearings, which is applied in vibration suppression adjustment, non-rotational vibration suppression, building components, etc., can solve problems such as instability, and the diameter of laminated rubber bearings is too large, so as to achieve low cost, Lightweight, responsive effects

Inactive Publication Date: 2005-09-07

BEIJING UNIV OF TECH

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For economic considerations, the diameter of the laminated rubber bearing cannot be too large, and its horizontal displacement may exceed its deformation limit, resulting in instability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

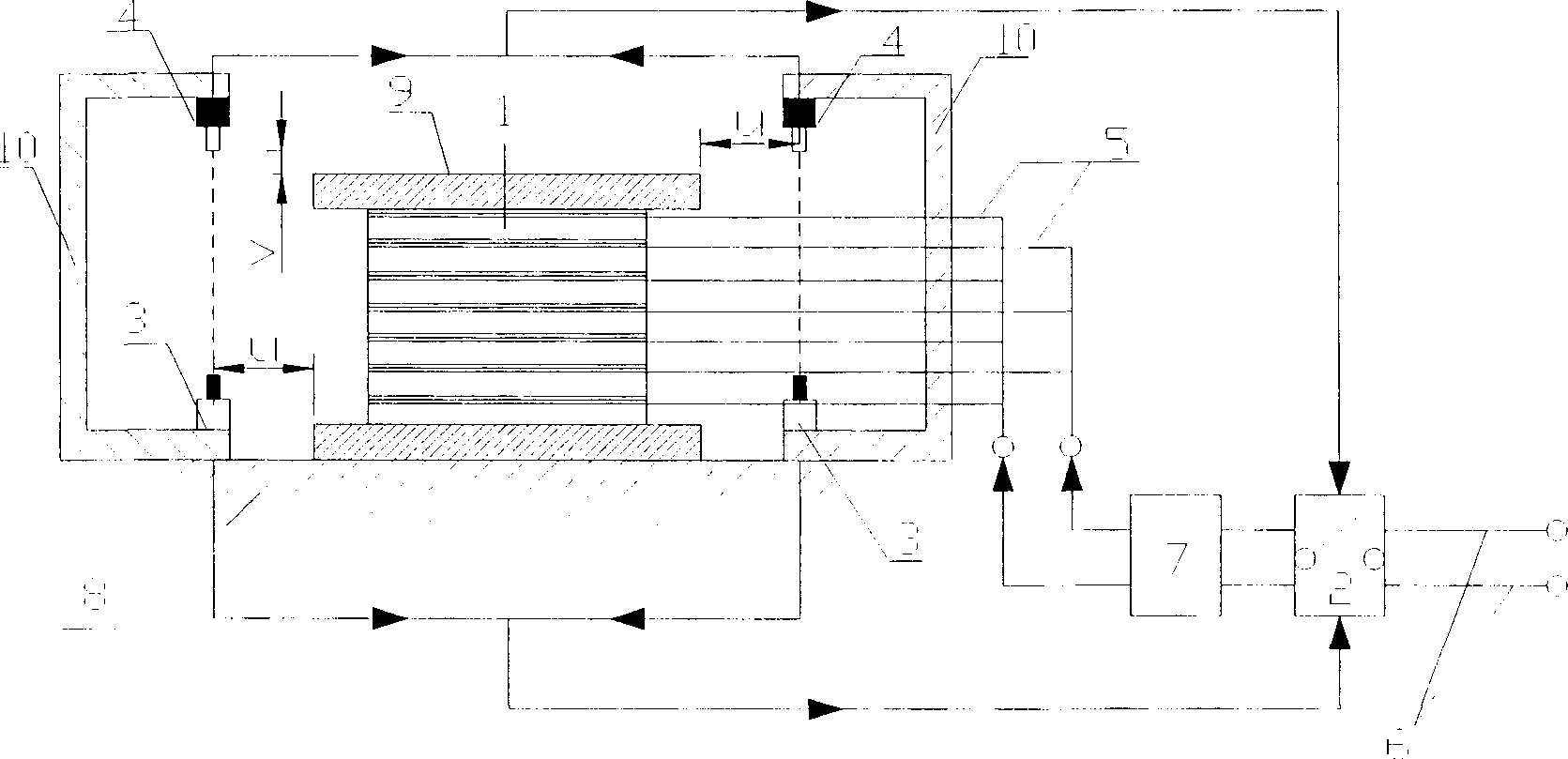

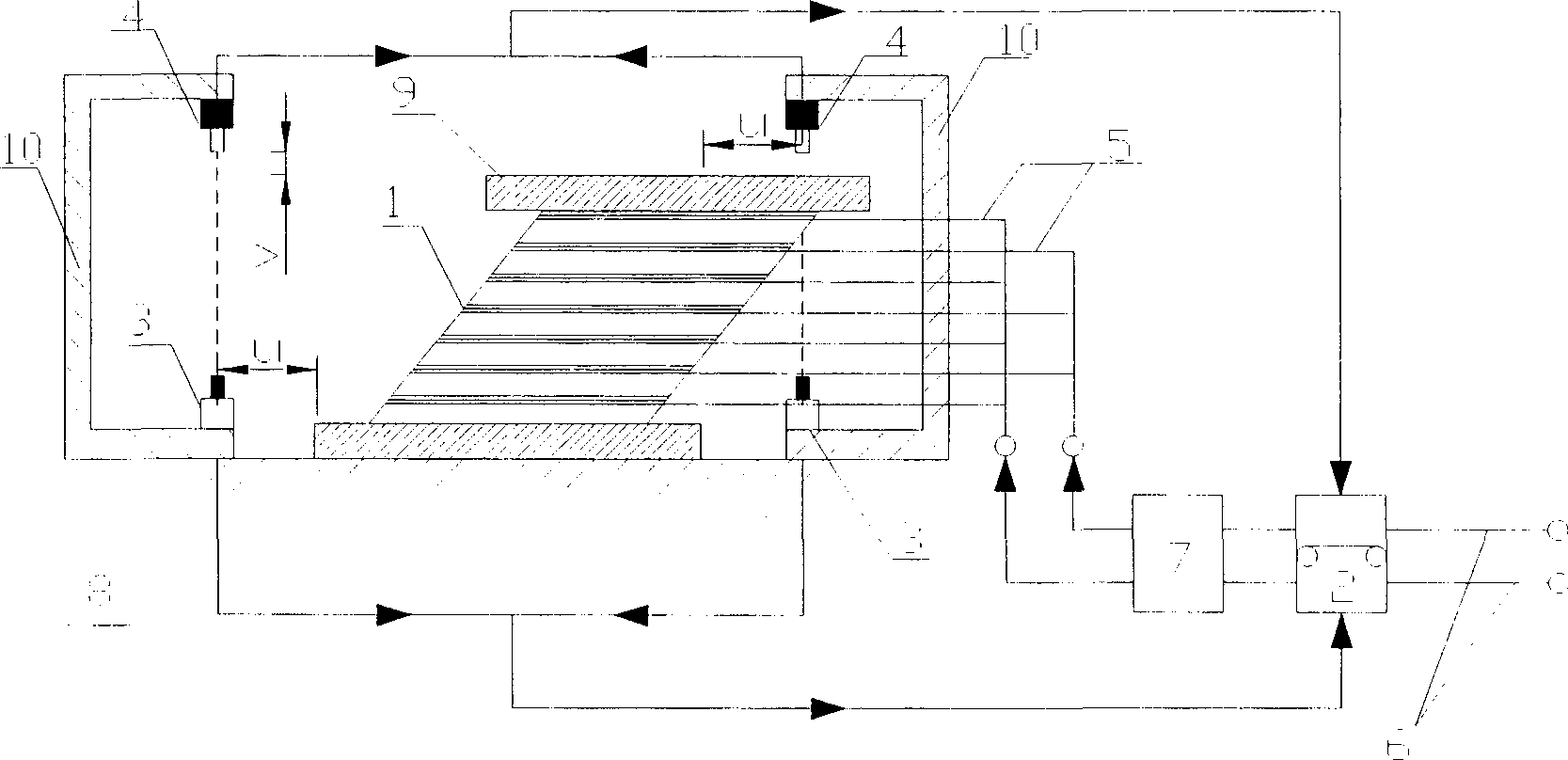

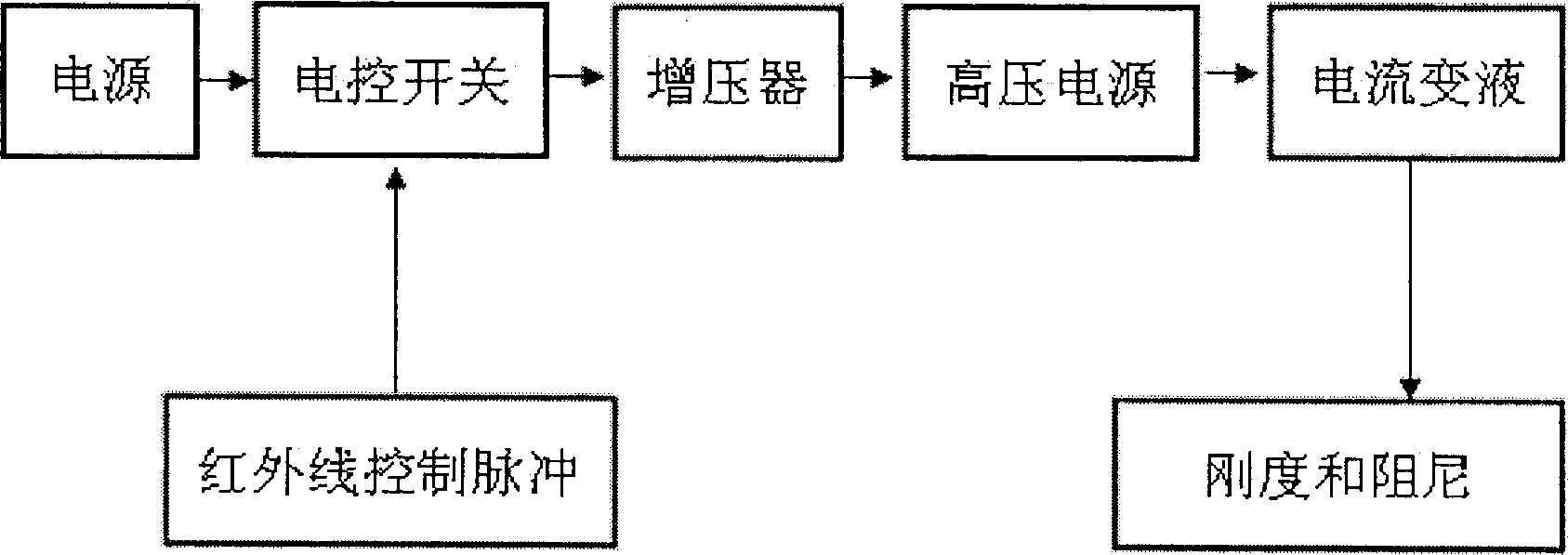

[0016] according to Figure 1 ~ Figure 3 The technical scheme of the variable stiffness and variable damping passive control device of the electrorheological composite laminated rubber bearing shown in the present invention is realized by assembling commercially available and designed and processed parts into one. In this device, conventional bolts and threads are used to connect the components.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a current variable compounding stacking rubber supporting rigidity and damp variable passiveness control device that belongs to structure trembling insulated and libration control technology field. The device includes two steel frames, infrared emitter and receiver, electric controlled switch, supercharger and electric working circuit. When the horizontal displacement of the current variable compounding stacking rubber supporting caused by the loading libration is larger then the preset distance, the infrared receiving channel would be cut off, and the electric controlled switch is power on. The high voltage would inflict on the steel board and the state of current variable liquid would be changed to supply additive rigidity and damp. The invention is simple structure, small volume and no energy consumption.

Description

technical field [0001] The invention relates to a passive control device with variable stiffness and variable damping of an electrorheological composite laminated rubber bearing, which belongs to the technical field of structure isolation control and vibration control. Background technique [0002] Laminated rubber bearing isolation is a relatively mature engineering isolation technology. Through the isolation device, the upper structure of the building is "isolated" from the foundation, and the dynamic characteristics of the upper structure are changed, which can greatly reduce the impact of earthquakes on the upper structure. In order to achieve the shock absorption effect of "overcoming rigidity with softness". The laminated rubber bearing is made of rubber layer and steel plate layered and bonded by high temperature vulcanization. When the rubber bearing bears the vertical load, the lateral deformation of the rubber layer is restrained, so that the rubber bearing has a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/98F16F9/30F16F9/53

Inventor 杨林闫维明周锡元蒋华戈黄浩华

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com