Vibration roller fiber-opening method and fiber-opening machine

A vibratory and roller technology, applied in the direction of fiber mechanical separation, mechanical treatment, fiber treatment, etc., can solve the problems of high labor intensity, messy fibers, large randomness, etc., to solve the problems of endless degumming, high production efficiency, and labor intensity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

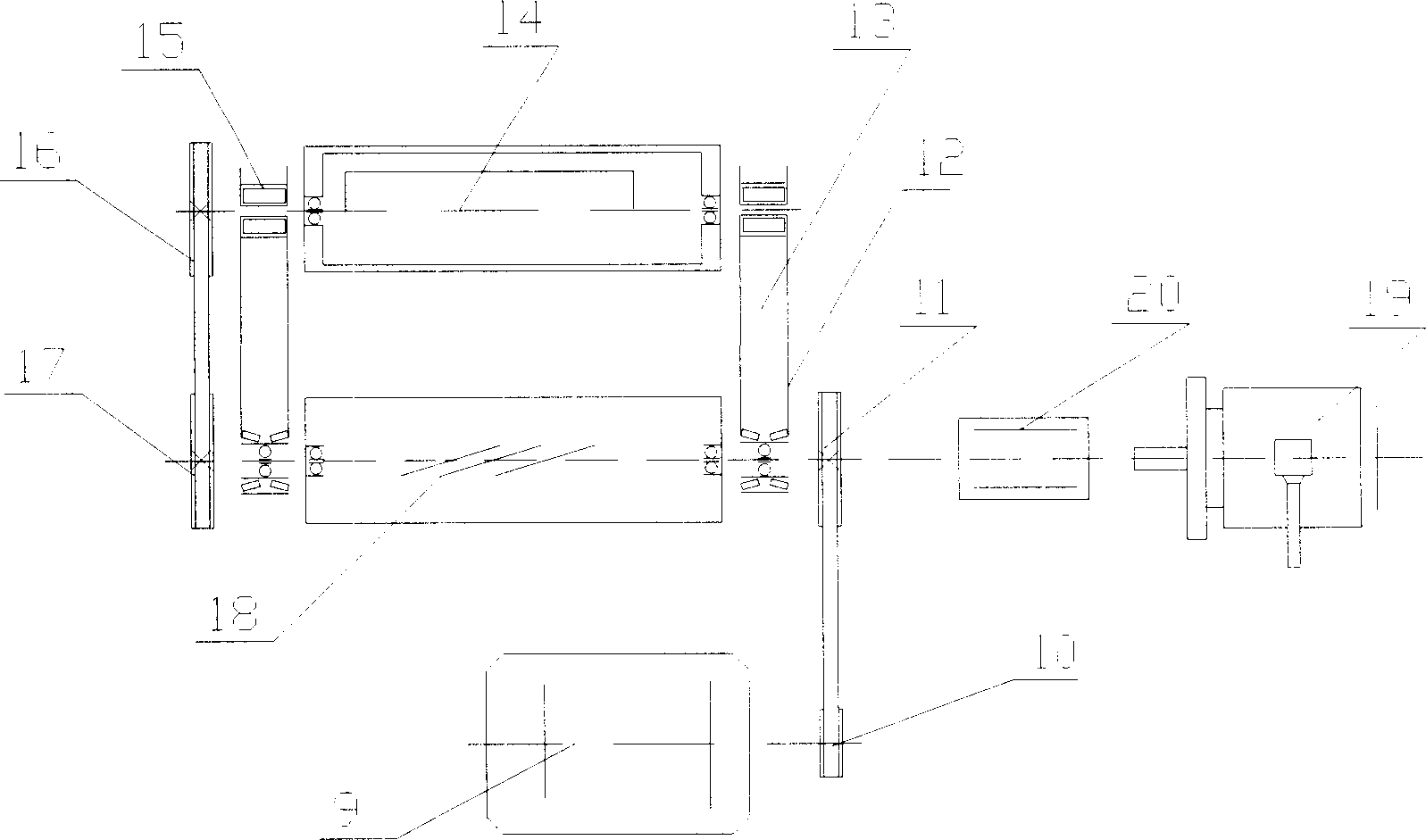

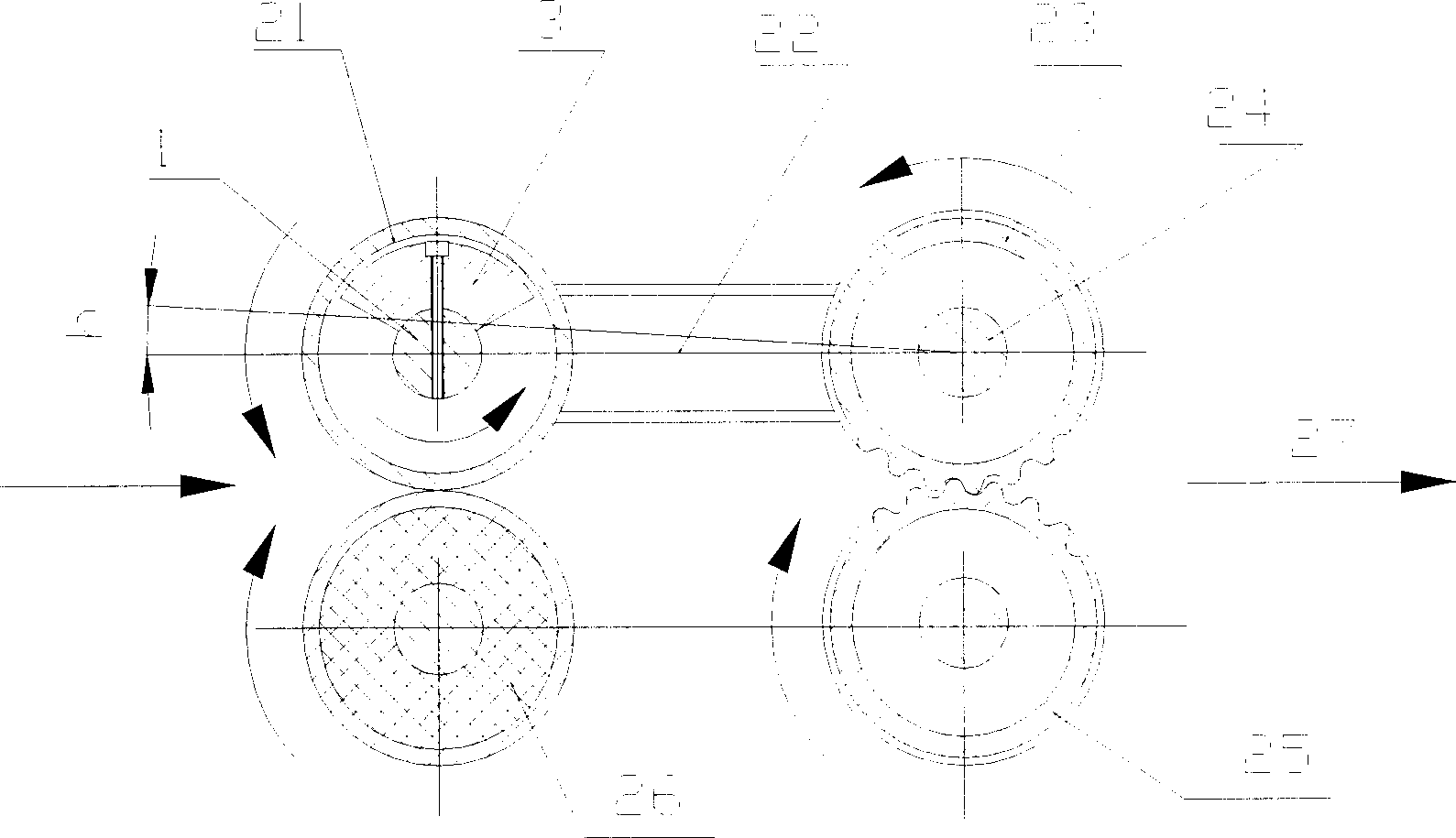

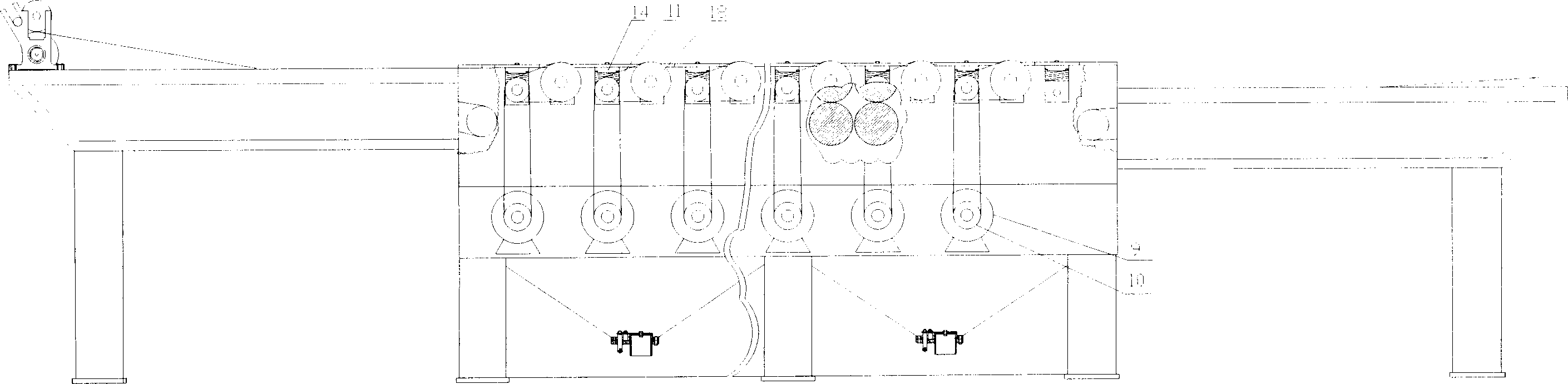

[0033] refer to Figure 1 to Figure 4 , vibrating roller opener of the present invention comprises frame, the cabinet that is positioned on frame and the conveyor belt that is positioned at the bottom roller on the cabinet and two ends, is positioned at the motor below the frame through speed reducer, V-belt (or chain) ) and the gear drive the helical tooth bottom roller (25) and the anvil roller roller (26) to rotate respectively. The vibrating roller assembly (14) is driven by the motor (9) through the transmission pulleys (10, 11), and then through the central shaft and the pulleys (16, 17) to drive the eccentric block shaft (1), and the eccentric block shaft is supported by the swing arm bearing. The other end of the swing arm is supported on the helical tooth roller bearing seat by a cone bearing, which can make the helical tooth roller bearing seat rise, fall and float according to the thickness of the raw material, so that the raw material can pass through smoothly.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com