Method for measuring type dynamic balance unbalance amount

A measurement method and balance technology, applied in static/dynamic balance test, measuring device, wheel test, etc., can solve the problems of increasing detection time and difficulty, affecting tire detection efficiency, increasing production cost, etc., and achieve reliable measurement standards and the effect of the frame of reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

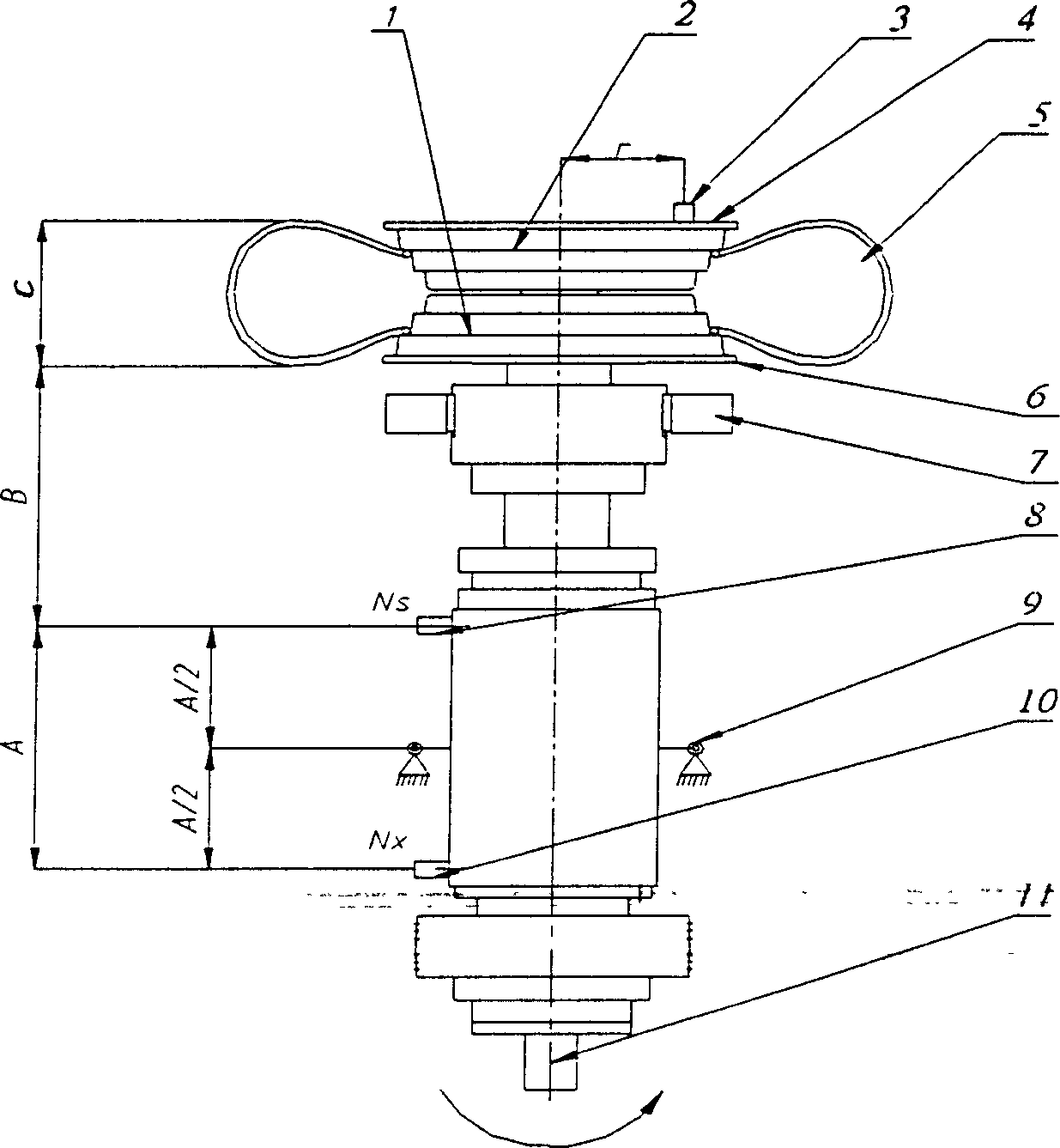

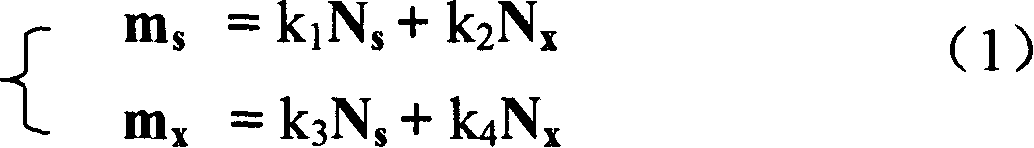

[0060] Embodiment 1, combining figure 1 The structure of the dynamic balance testing machine shown, the measurement method of the present invention, after determining and installing the dynamic balance testing machine in place, select any tire to be tested with eccentric mass m, first establish the calibration coefficient k and the tire to be tested The linear mathematical expression between the unbalanced mass m and the measured unbalanced force couple N on the correction surface, the derivation process of the linear model is:

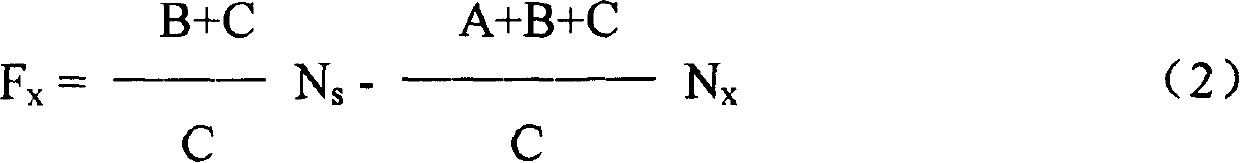

[0061] first step, such as figure 1 As shown, according to the principle of moment balance, the moments of the upper and lower correction surfaces are calculated respectively, and the centrifugal force generated by the upper and lower correction surfaces of the tested tire is calculated.

[0062] That is, the moment of the upper correction surface should be calculated, and the result should be 0, that is, ΣMs=0. Solutions have to:

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com