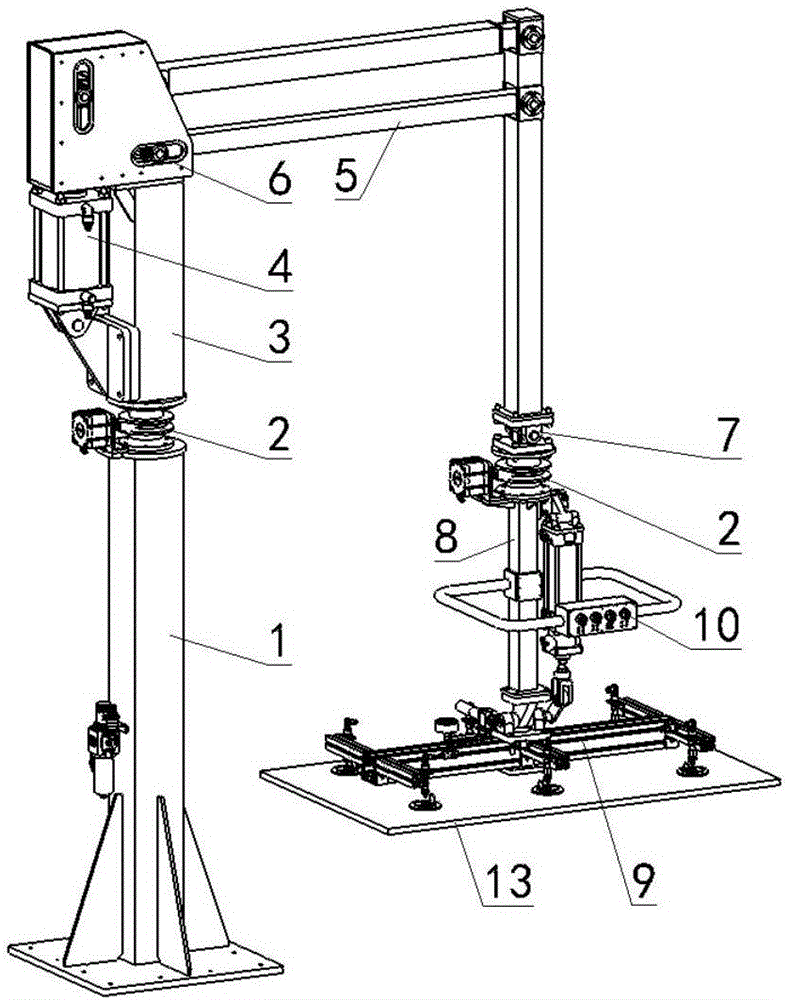

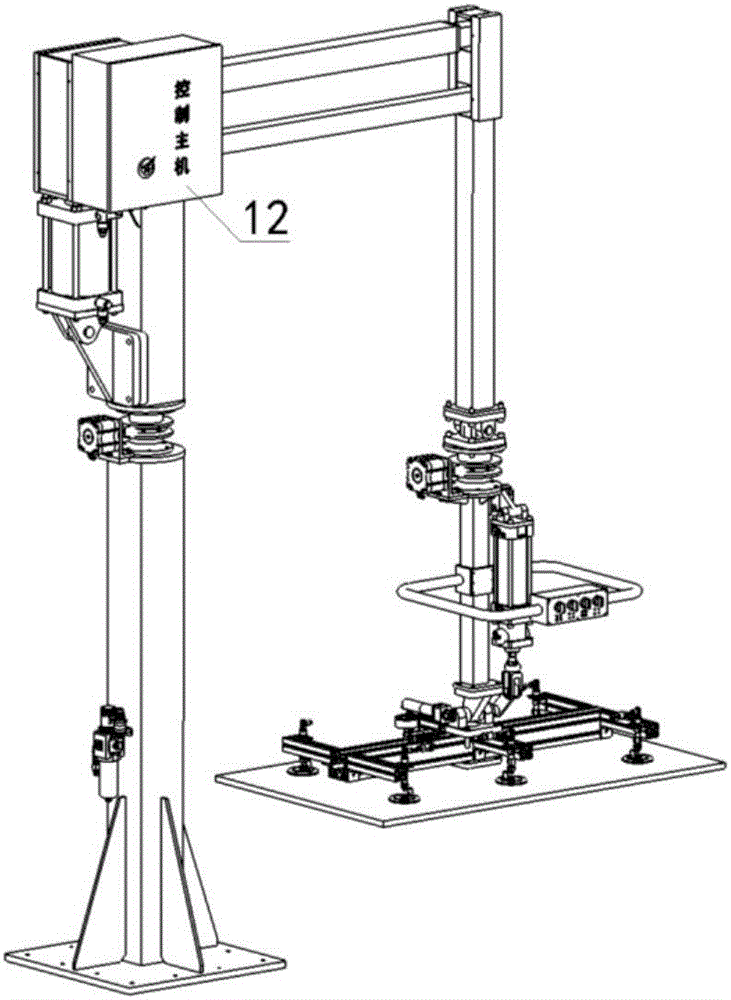

Assistance manipulator and control system thereof

A technology of power-assisted manipulators and parallelograms, which is applied in the directions of manipulators, program-controlled manipulators, and manufacturing tools, and can solve problems such as low efficiency, long periods of workshop cranes, and affecting production progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

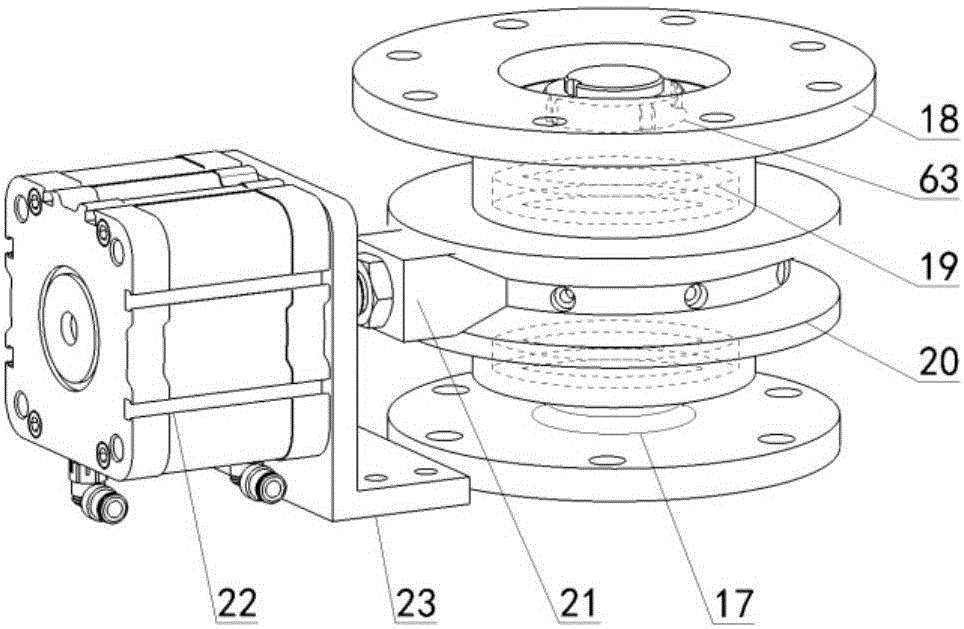

Method used

Image

Examples

Embodiment approach

[0041] First, connect the plant air source to the air source processing module 14 of this application with the air pipe for filtering and decompression, and then open the switch module 15 to inflate the system. Can not move, by operating the brake / release selection button on the control interface 57, release the brake of the system, move the joystick 45 to fit the vacuum chuck 44 and the workpiece 13, start the vacuum button 50, and the workpiece 12 is adsorbed on the fixture 9 Up, start the load button 47, the workpiece 13 is automatically balanced, move the joystick 45 up and down, left and right, move the workpiece 13 to the target position, start the forward rotation button 49, rotate the workpiece 13 from the horizontal state to the vertical state, and place the workpiece 13 close to the placement frame , start the no-load button 47 and the atmospheric button 50, the workpiece 13 breaks away from the manipulator clamp 9, and the manipulator regains its balance. When stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com