Semiconductor device and manufacturing method thereof, and liquid crystal module and semiconductor module having the same

A manufacturing method and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as reduced reliability and poor device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

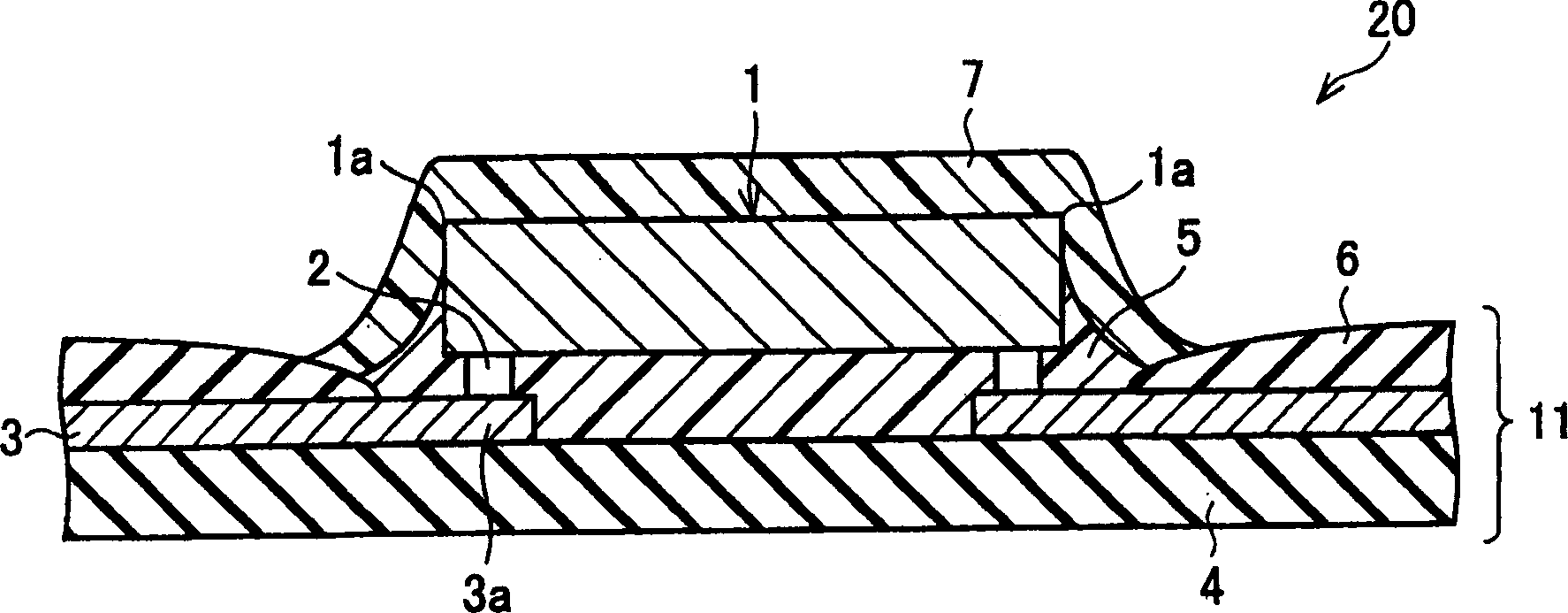

[0052] according to figure 1 And Fig. 7 (a), Fig. 7 (b), describe as follows with respect to an embodiment of the present invention.

[0053] figure 1 is a cross-sectional view showing a schematic structure of a semiconductor element mounting region in the semiconductor device of this embodiment.

[0054] like figure 1 As shown, the semiconductor device 20 of this embodiment is equipped with a wiring substrate 11 and a semiconductor element 1, and the semiconductor element 1 is mounted on the wiring substrate 11 using an underfill 5 as a first sealing resin layer, and at the same time, mounted on the wiring substrate 11. The back surface of the semiconductor element 1 on 11 has a structure completely covered with the top coat layer 7 as the second sealing resin layer.

[0055] The semiconductor element 1 described above is used for drive control of an electronic device in which the semiconductor device 20 is mounted. The above-mentioned semiconductor element 1 is formed...

Embodiment 2

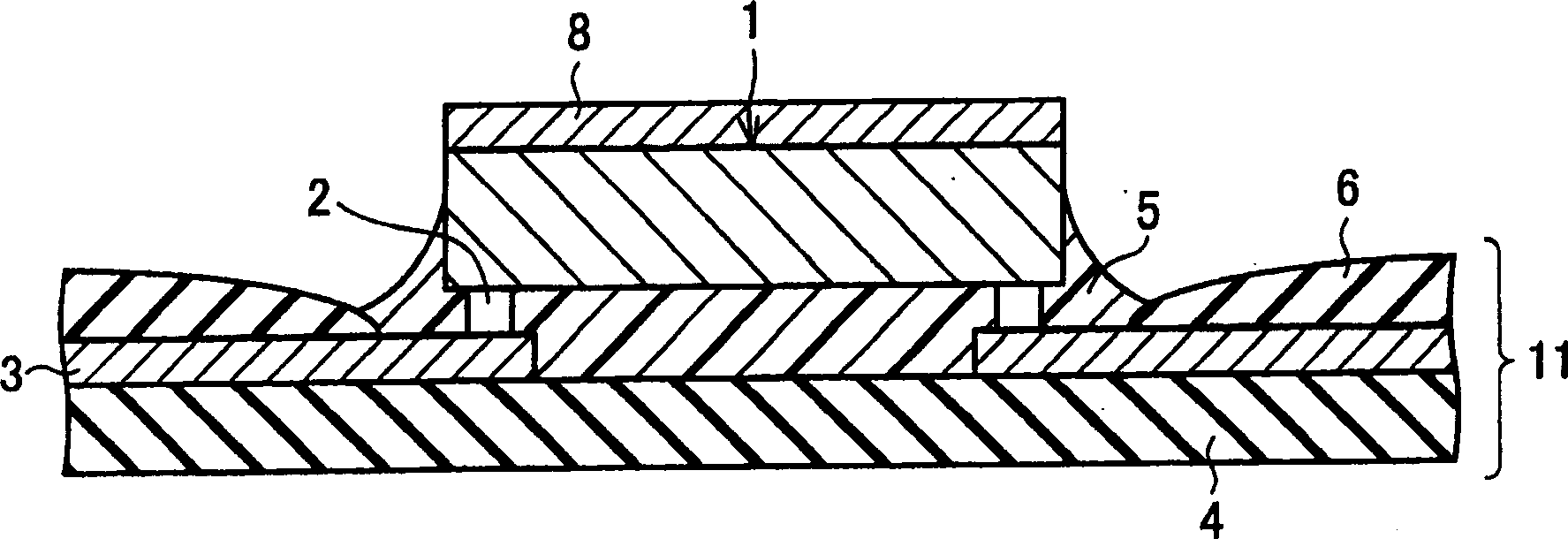

[0092] According to FIG. 2(a) and FIG. 2(b), an embodiment of the present invention is described as follows. In addition, for the convenience of description, the constituent elements having the same functions as those of the first embodiment are given the same reference numerals, and their descriptions are omitted. In this embodiment, differences from the first embodiment described above will be mainly described.

[0093] Fig. 2 (a) and Fig. 2 (b) are main part sectional views showing the manufacturing method of the semiconductor device of the present embodiment, and these Fig. 2 (a) and Fig. 2 (b) show the semiconductor device in the semiconductor device of the present embodiment Cross-section of the component packaging area.

[0094] As shown in Fig. 2 (a) and Fig. 2 (b), the semiconductor device 20 of the present embodiment has the upper surface (back side, i.e. with On the surface opposite to the active surface as the functional circuit surface, a metal plate 8 having hi...

Embodiment 3

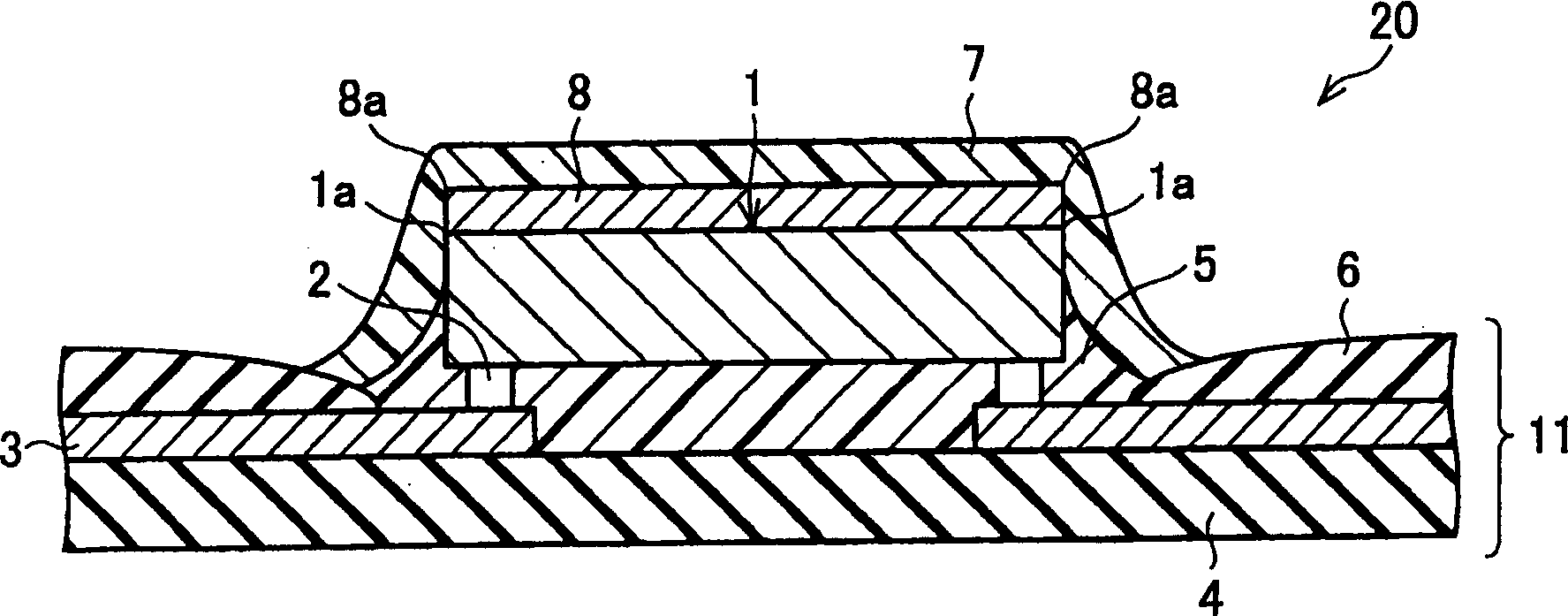

[0108] according to Figure 3(a) ~ Figure 3(c) and Figure 4 , an embodiment of the present invention is described as follows. In addition, for the convenience of description, the constituent elements having the same functions as those of Embodiments 1 and 2 are denoted by the same reference numerals, and their descriptions are omitted. In this embodiment, differences from the first embodiment described above will be mainly described.

[0109] Figure 3(a) ~ Figure 3(c) is a sectional view of main parts showing the method of manufacturing the semiconductor device of this embodiment, and these Figure 3(a) ~ Figure 3(c) A cross section of a semiconductor element mounting region in the semiconductor device of this embodiment is shown.

[0110] As shown in FIG. 3( c ), the semiconductor device 20 of this embodiment has the same structure as the semiconductor device 20 of the above-mentioned embodiment 2, but the manufacturing process is different.

[0111] Next, a method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com