Welding method and circuit board using same

A welding method and circuit board technology are applied in the direction of assembling printed circuits, circuits, and printed circuits with electrical components. The effect of good electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

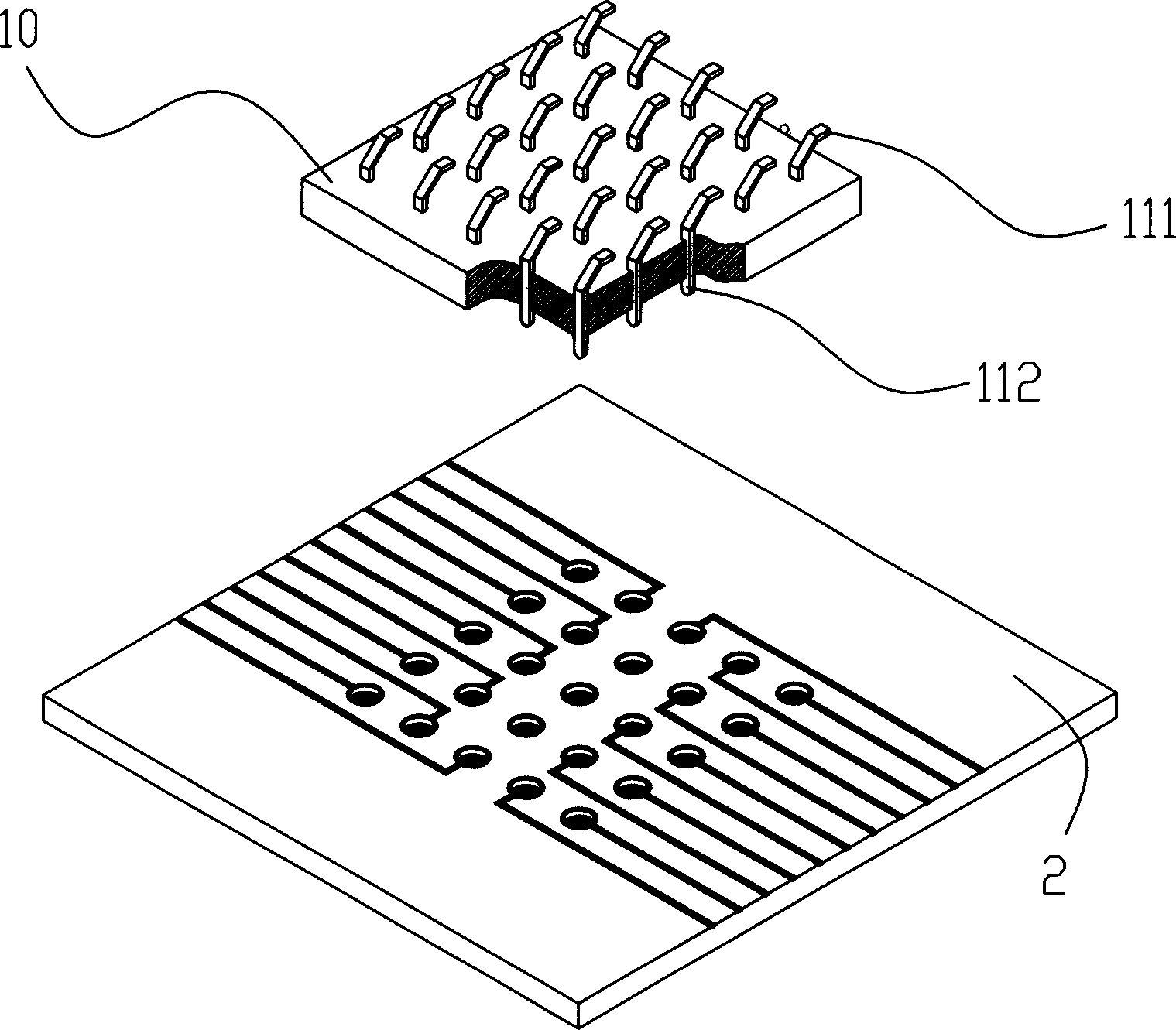

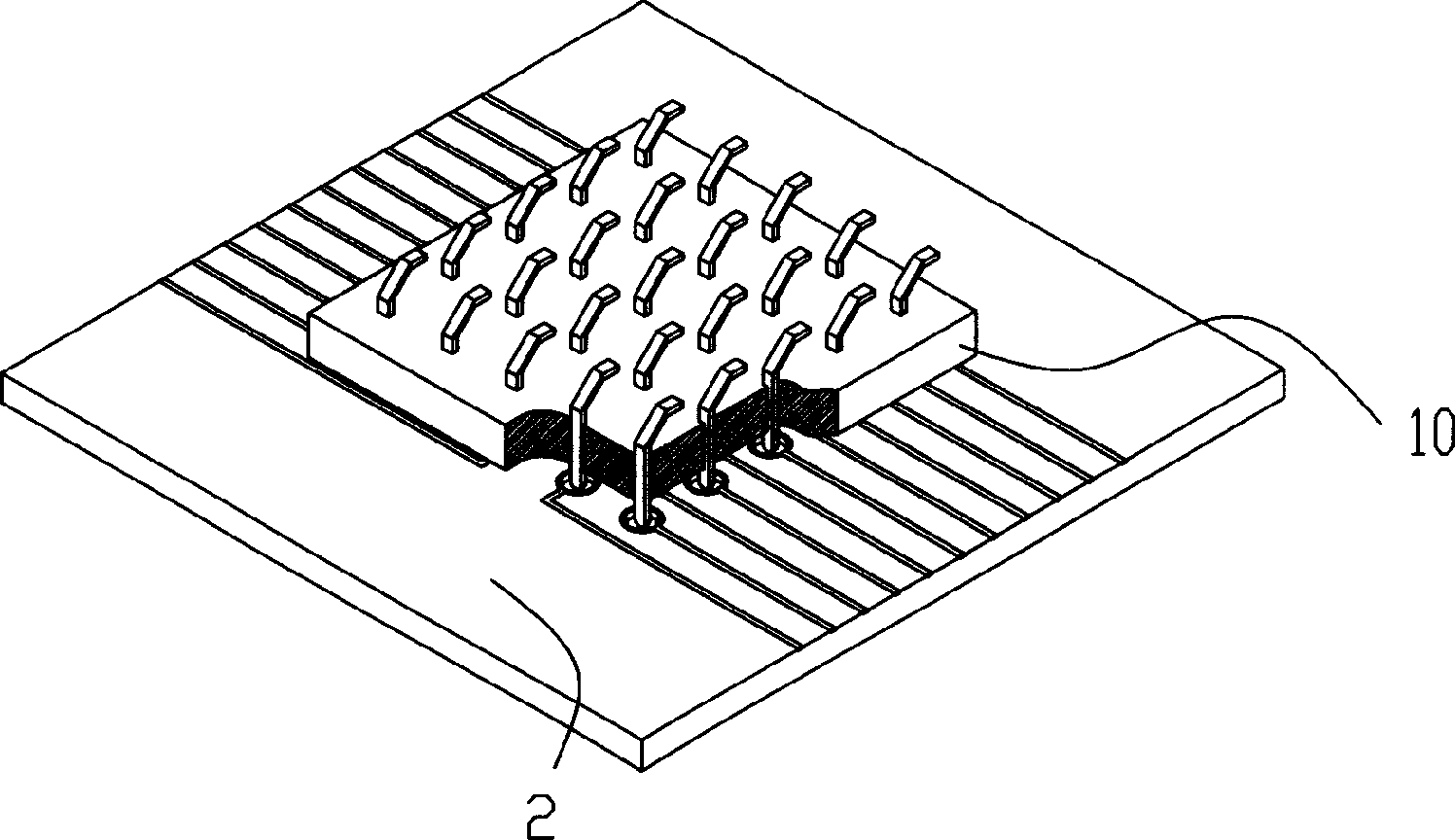

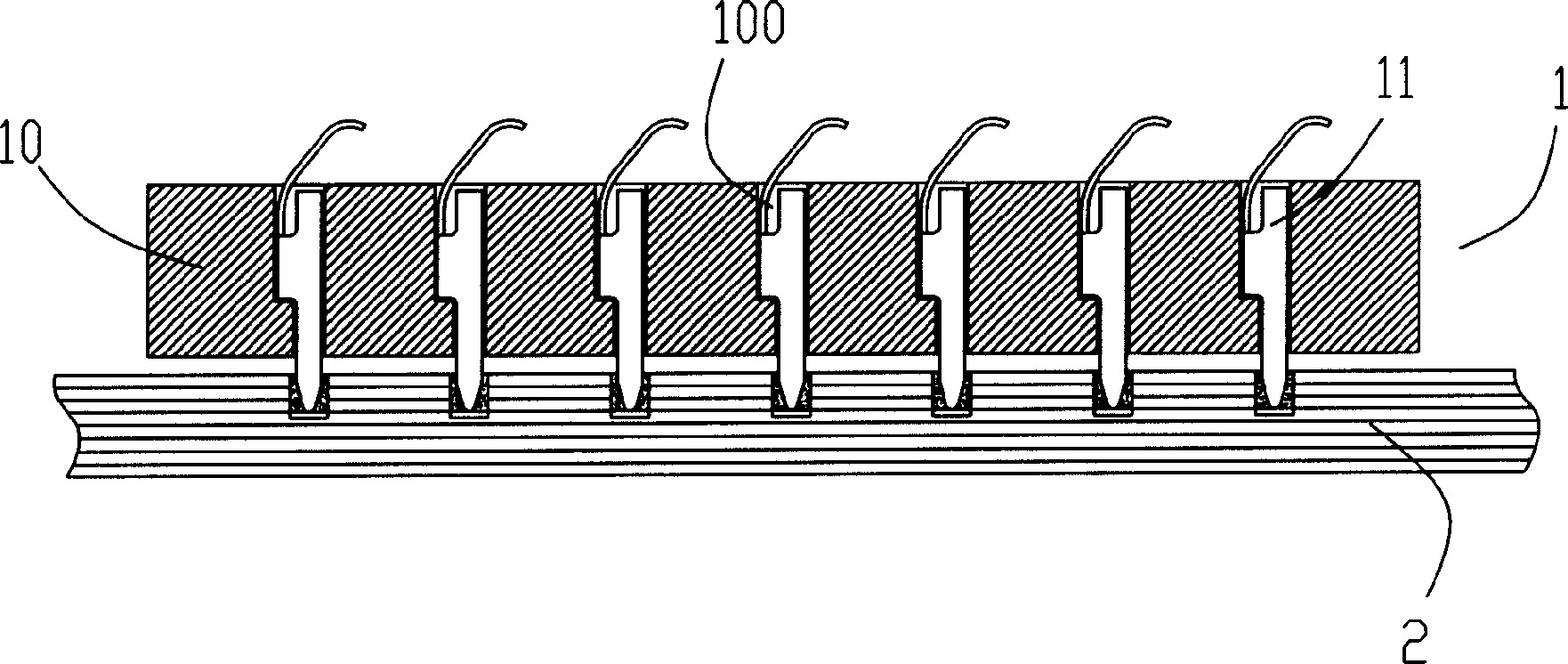

[0018] refer to Figure 1 to Figure 4 , The welding method of the present invention can weld two electronic components together, and these two electronic components can be any other electronic components such as chips or circuit boards. Now only the soldering of the electrical connector to the circuit board using this soldering method will be described in detail.

[0019] Wherein the electrical connector 1 includes an insulating body 10 and a needle-shaped welding end (conductive terminal 11 in this example), the insulating body 10 is provided with a terminal receiving hole 100, and the conductive terminal 11 is placed in the terminal receiving hole 100 of the insulating body 10, It includes a holding part 110, a contact part 111 extending upward from the holding part 110, and a needle-shaped welding part 112 extending downward from the holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com