Method for connecting conductor and solder and electronic element in said connecting method

An electronic component and connection method technology, which is applied to the connection between conductors and solder and the field of electronic components using this connection, can solve the problems of increased processing cost, tin ablation, and electronic components cannot be electrically connected to the circuit board. Simple processing and good electrical conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

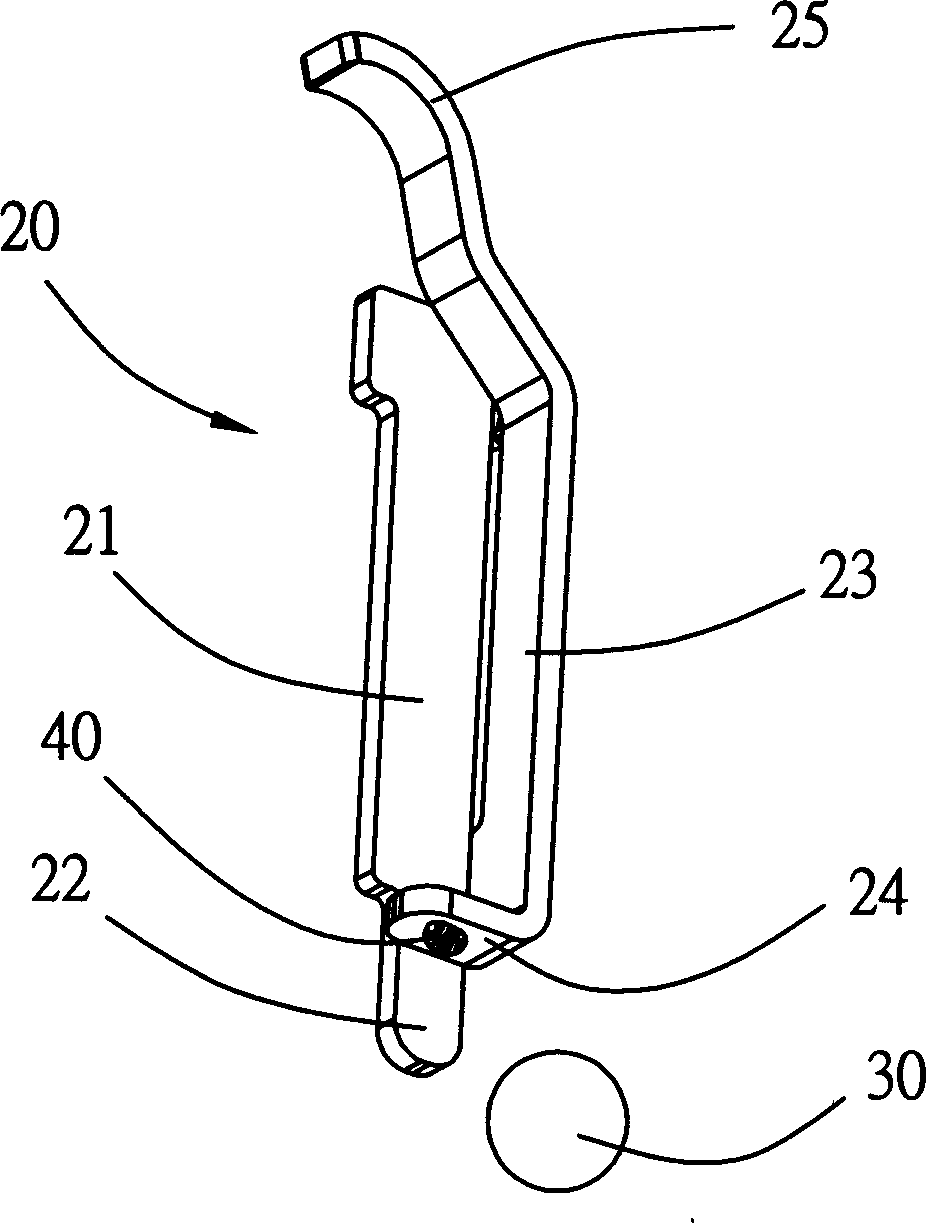

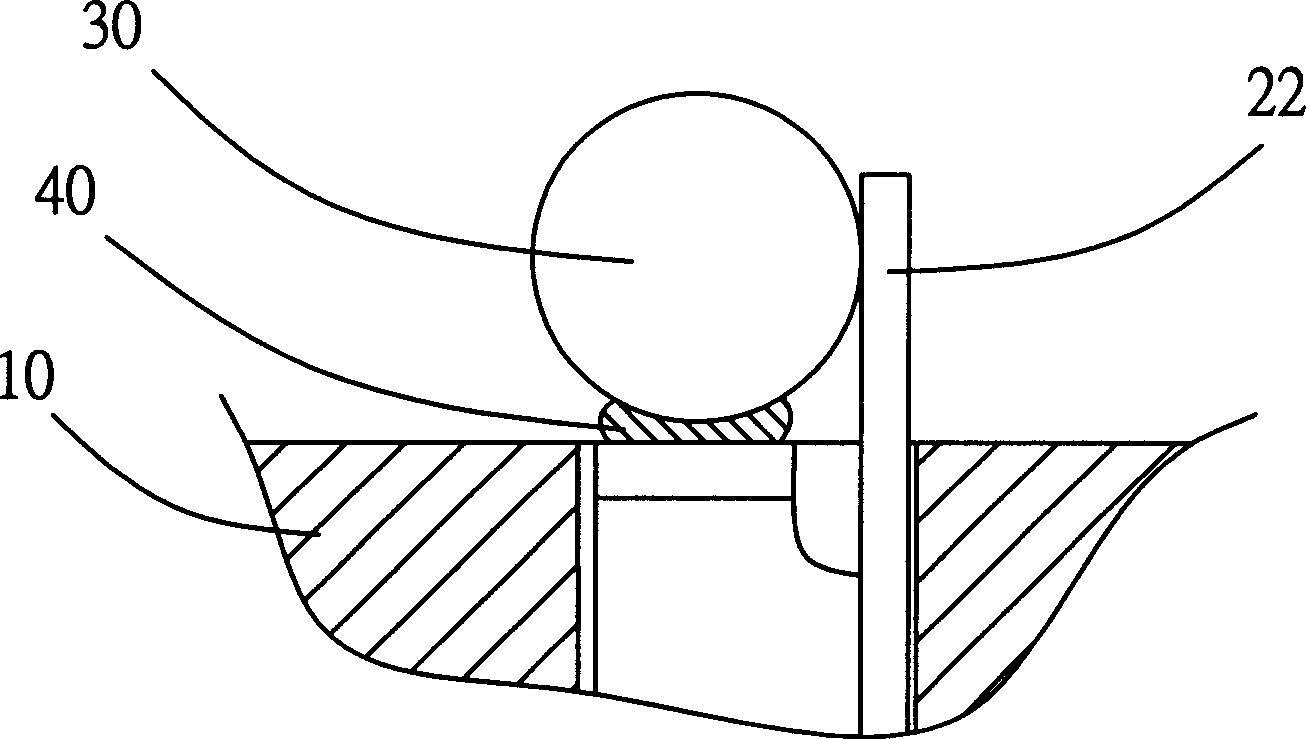

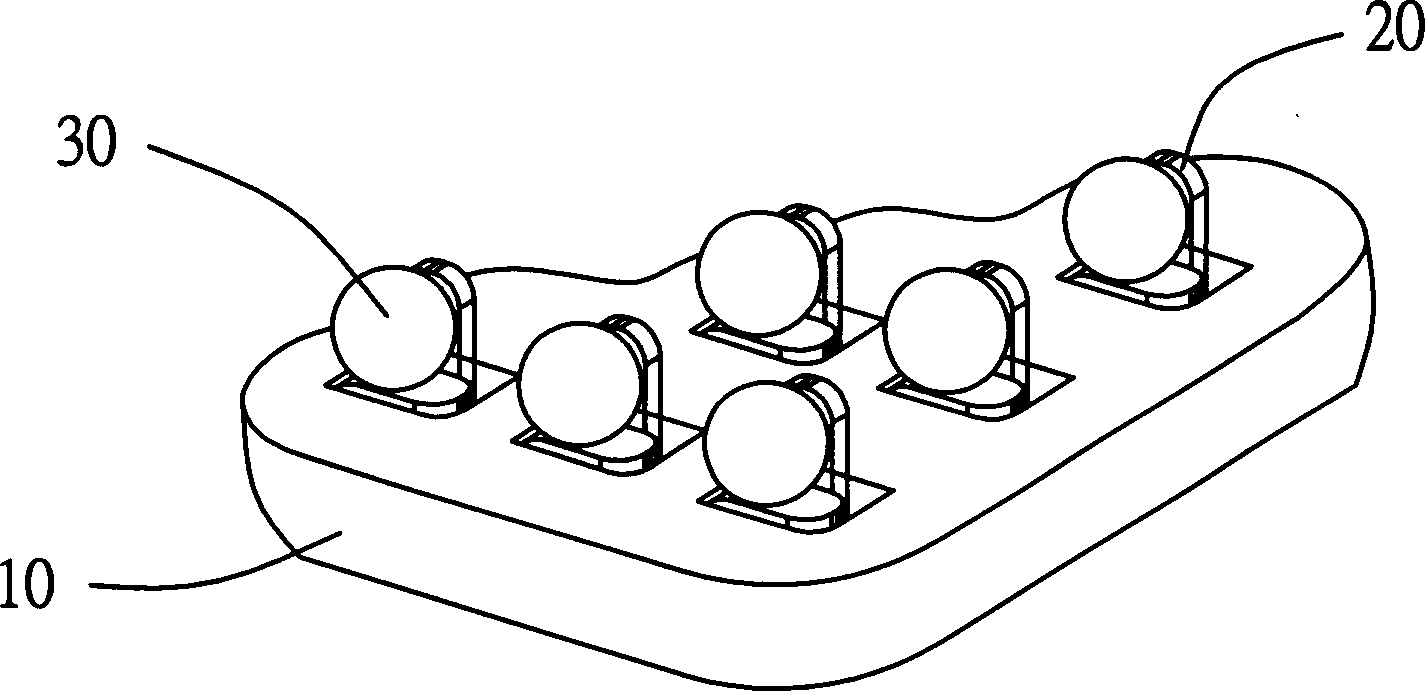

[0016] Such as figure 1 , figure 2 , image 3 As shown, the electronic component of the present invention includes an insulating body 10 and a plurality of conductors 20 and solder balls 30 accommodated in the insulating body 10. The conductor 20 has a fixing portion 21 fixed in the insulating body 10, and the fixing portion 21 The welding part 22 extending downward, and the elastic arm 23 extending vertically from one side of the fixing part 21, the lower end of the elastic arm 23 is vertically bent into a horizontal shape to form a connecting part 24 to connect with the solder ball 30, and the upper end passes through The terminal is bent multiple times to form a contact portion 25 with certain elasticity, so as to elastically compress and contact with the lead portion (not shown in the figure) of the docking electronic component.

[0017] When assembling, first coat (other installation methods such as dots and stickers) on the bottom of the conductor connection part 24 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com