Method for setting interception valve for pipeline water purification and its special interception valve

A water purification device and pipeline technology, applied to indoor sanitary pipeline devices, separation methods, water supply devices, etc., to achieve the effect of solving the pressure bearing problem of containers, safe use, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

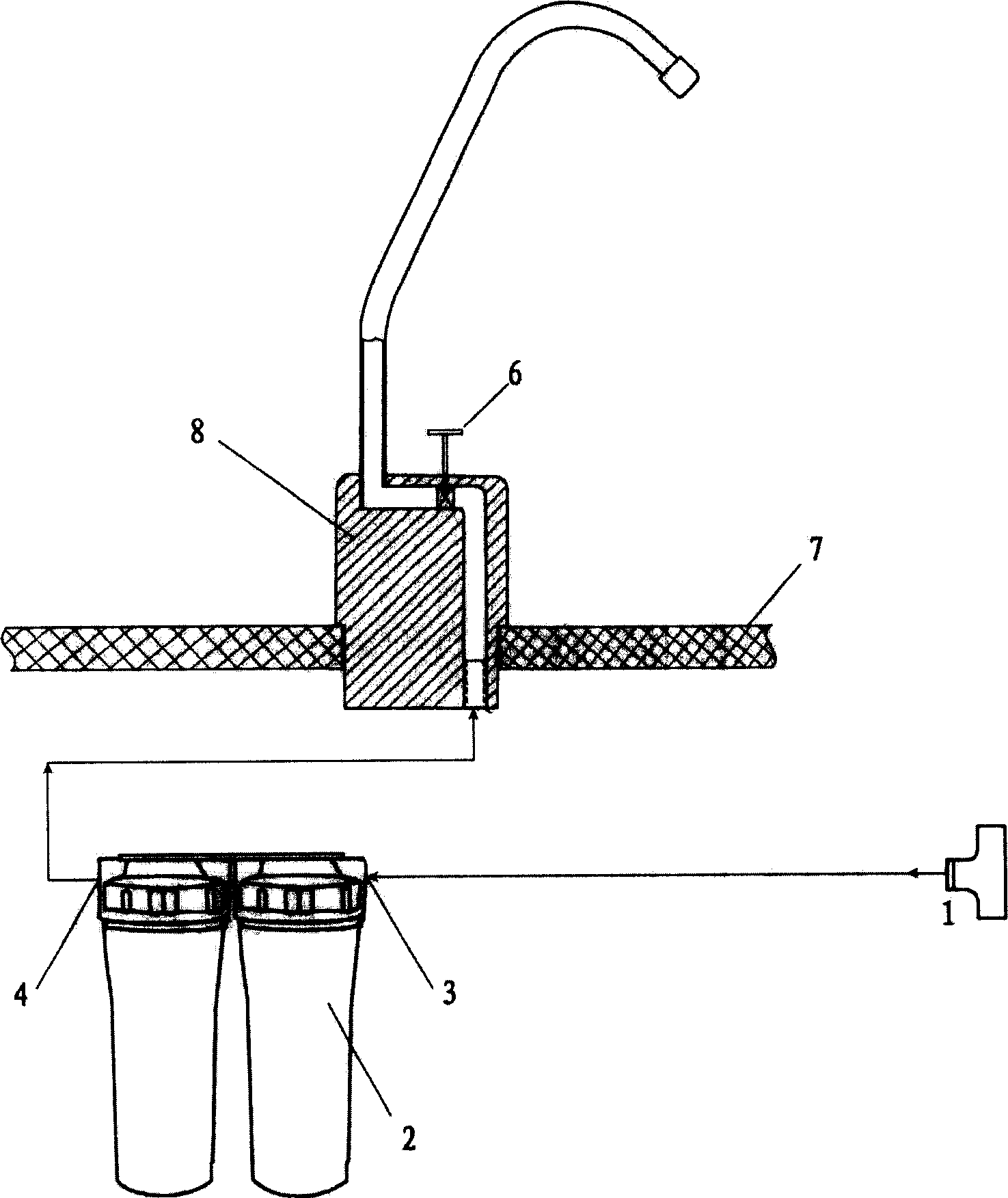

[0026] Such as figure 1 As shown, in the prior art, since most water purification equipments are not beautiful enough and need to occupy a certain installation space, it is usually the case that the water purification equipment is installed in a hidden place under the operating table 7 (such as in a cabinet, etc.). For the convenience of operation, installers often adopt common valves 6 installed on the operating table 7 of the water purification equipment 2 to control the outflow of purified water, but such installation will make all containers in the water purification equipment 2 always under pressure.

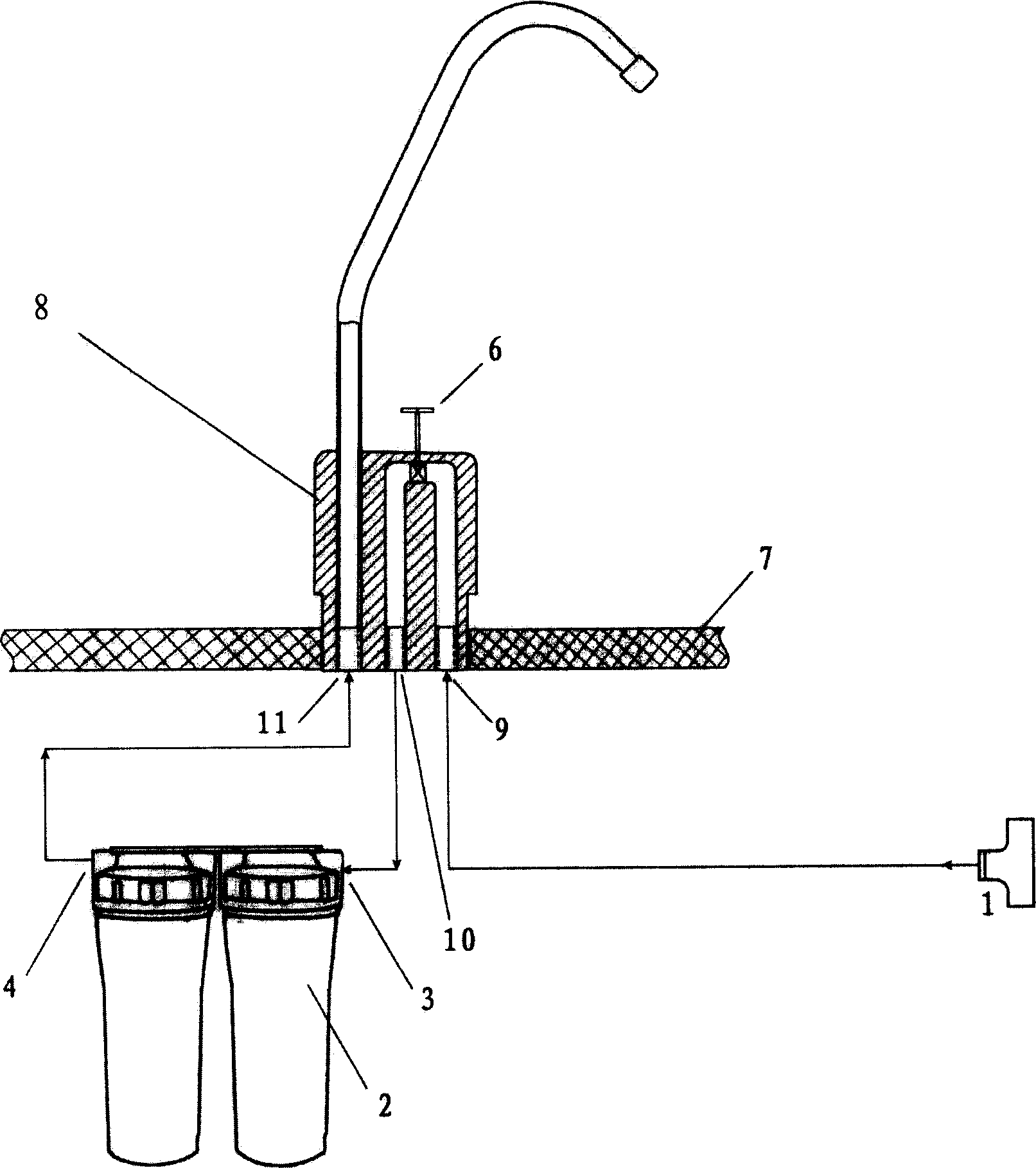

[0027] Such as figure 2 As shown, when the valve switch 6 is opened, the tap water flowing out of the tap water source tee interface 1 of the present invention flows into the valve body through the water inlet 9 of the U-shaped pipeline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com