Laminated formed body and method of manufacturing the formed body

A manufacturing method and molding technology, applied in the field of laminated products and its manufacturing, can solve the problems of increased cost, no product, easy intrusion, etc., and achieve the effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation, structure, The manufacturing method, steps, features and effects thereof are described in detail below.

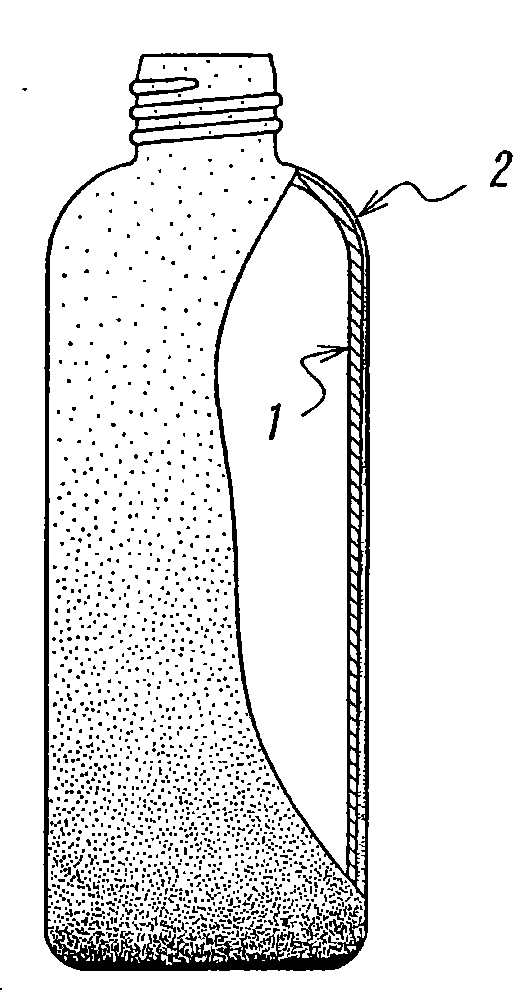

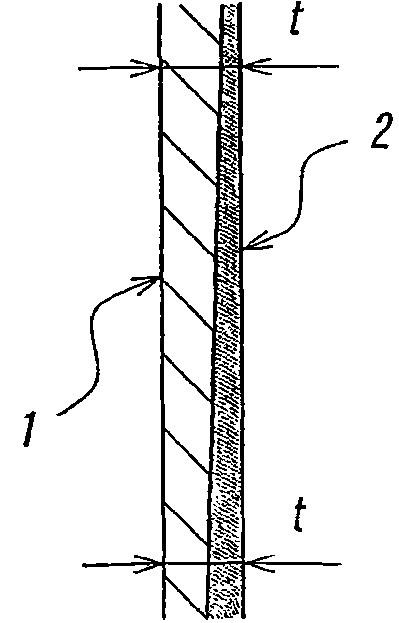

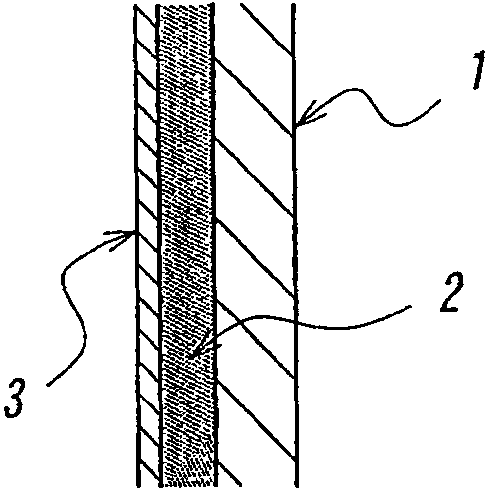

[0025] figure 1 It is an example of a blow molded product of a double-layer bottle-shaped container as a laminated product related to an embodiment of the present invention. A colored layer integrally arranged on the outside of the main body part 1 . The colored layer 2 is a layer in which the density of the color is gradually increased by gradually thickening from the mouth of the molded product to the bottom. Also, by gradually reducing the thickness of the main body portion 1 as the inner layer from the mouth to the bottom of the molded product, the overall thickness t of the laminated molded product is maintained at a substantially uniform thickness.

[0026] the above figure 1 The molded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com