Eutectic composite powdery-sintering assistant for manufacturing structural ceramic and production thereof

A technology of sintering aids and composite powders, which is applied in the field of ceramic production technology in the Ming Dynasty, to achieve excellent technical performance, lower sintering pressure, and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

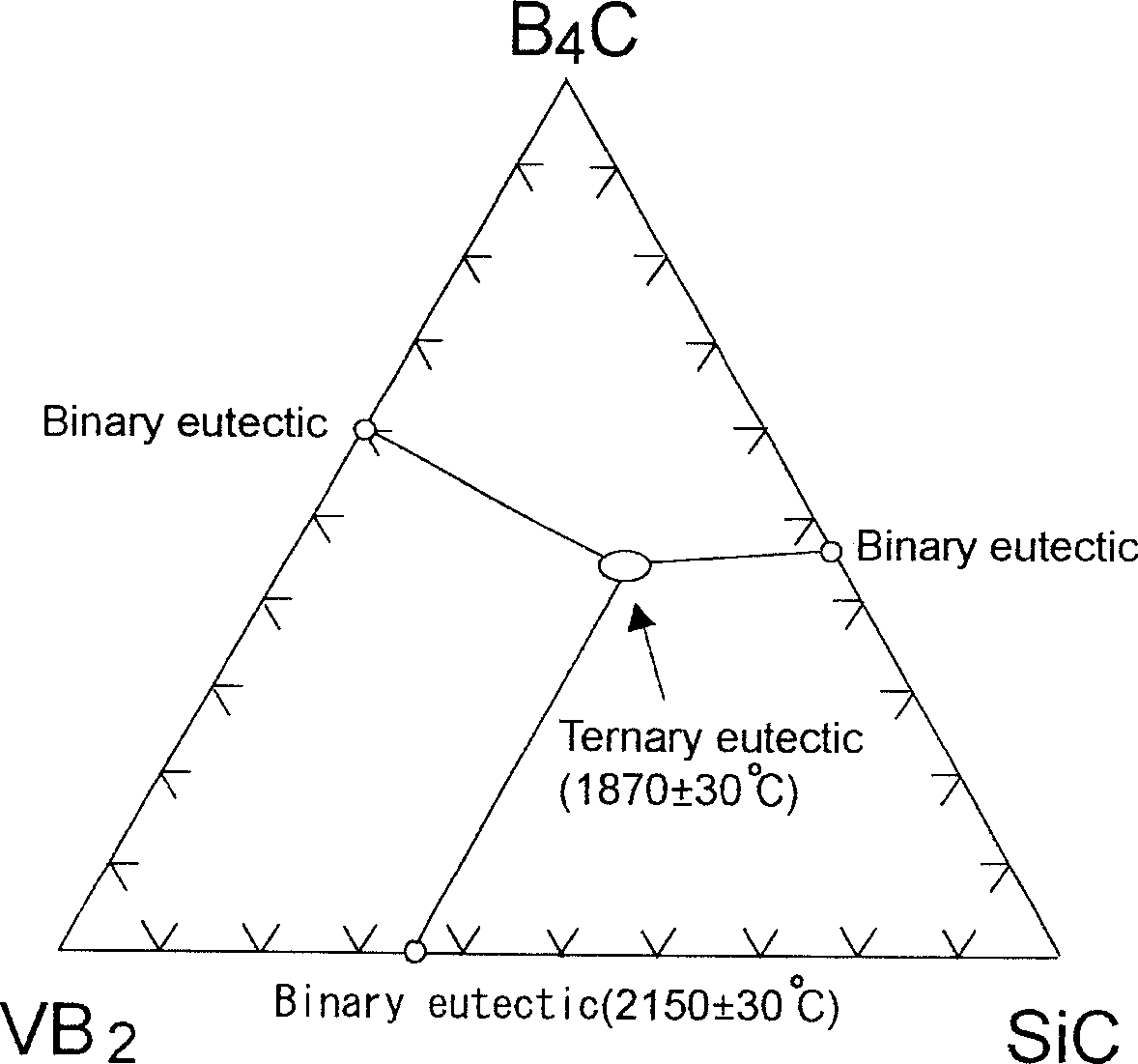

[0042] in figure 1 Medium SiC, VB 2 And B 4 C phase forms eutectic composite ceramic, VB 2 / SiC eutectic composite ceramic powder preparation formula is 67-71mol% VB 2 With 29-33mol% SiC, the melting temperature is 2150±30℃. VB 2 / SiC / B 4 The preparation formula of C eutectic composite ceramic powder is 20-24mol% VB 2 , 40-48mol% B 4 C, 30-36mol% SiC, melting temperature is 1870±30℃.

Embodiment 2

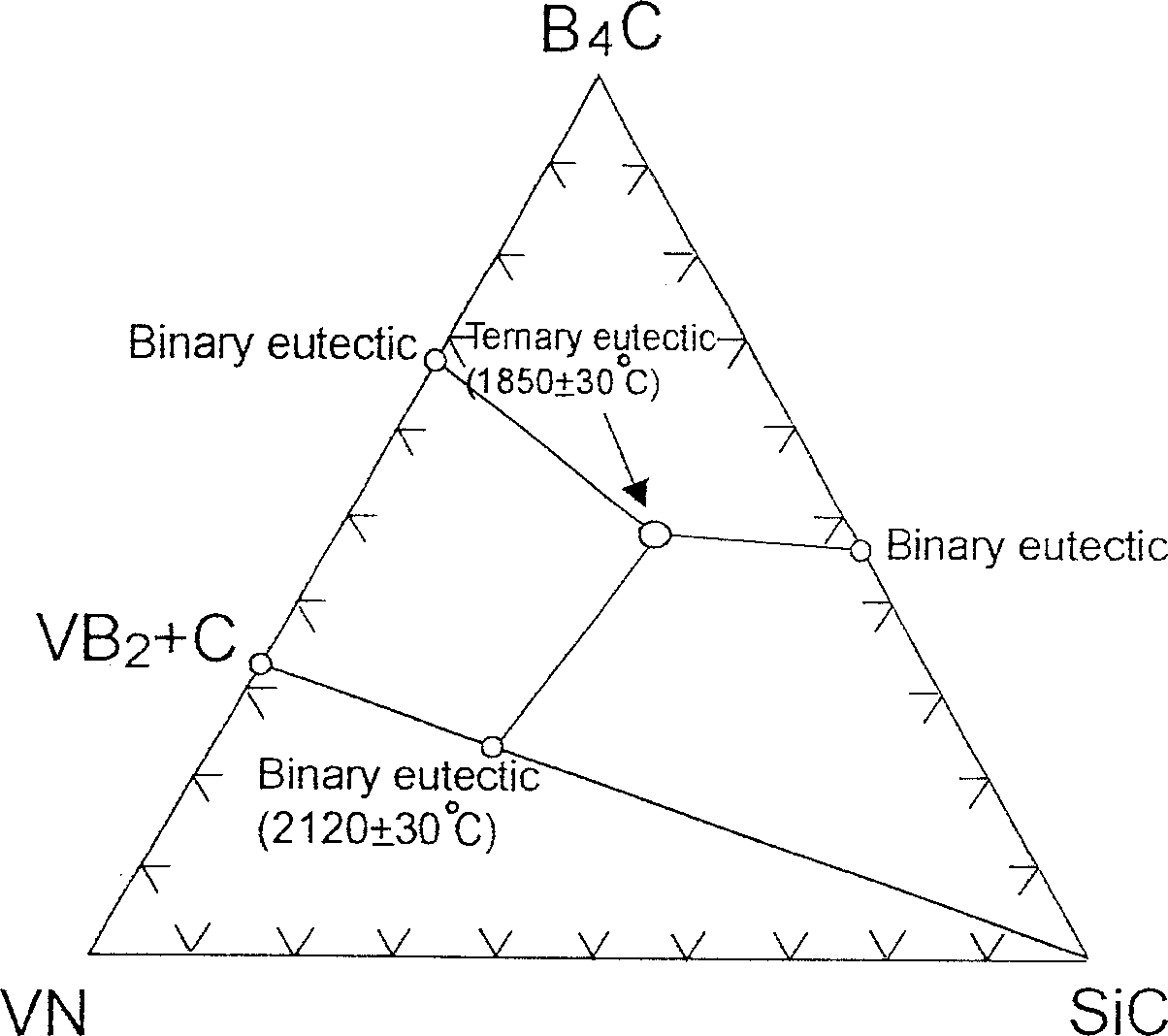

[0044] in figure 2 Medium SiC, VB 2 , B 4 C and C phases form eutectic composite ceramics. C / VB 2 / SiC eutectic composite ceramic powder preparation formula is 47-51mol% VN, 23-26mol% B 4 C. 24-28mol% SiC, melting temperature 2120±30℃. C / VB 2 / SiC / B 4 The preparation formula of C eutectic composite ceramic powder is 18-22mol% VN, 46-54mol% B 4 C. 26-34mol% SiC, melting temperature 1850±30℃. It can be seen from Examples 1, 2 that due to VB 2 / SiC, VB 2 / SiC / B 4 C, C / VB 2 / SiC and C / VB 2 / SiC / B 4 C and other eutectic composite ceramics have a melting temperature ratio VB 2 Or SiC or B 4 C is much lower. Therefore, using eutectic composite powder technology as a sintering aid, SiC or B can be prepared by liquid phase sintering at low temperature. 4 C and other hard-to-sinter ceramics.

Embodiment 3

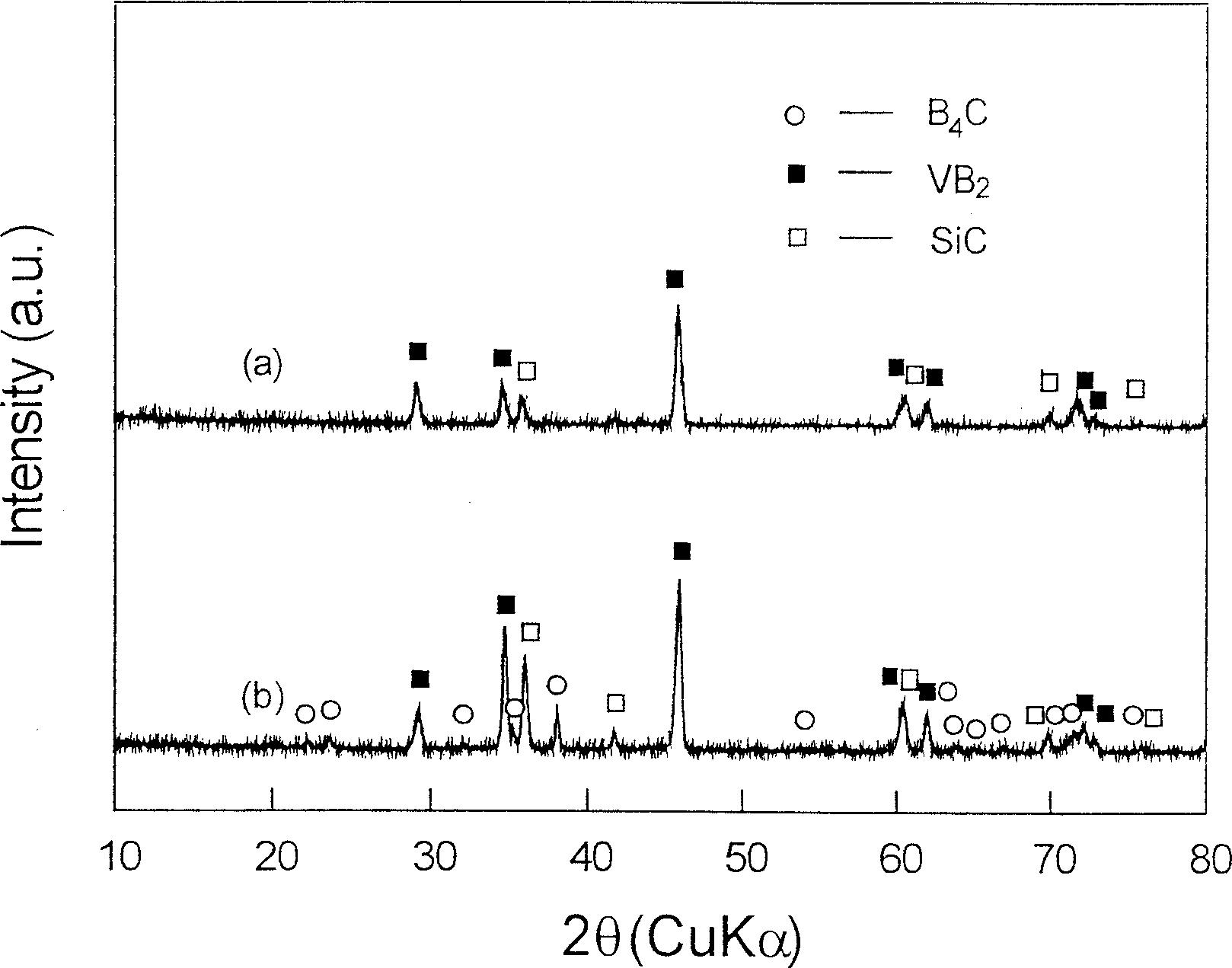

[0046] in image 3 In VB 2 And SiC or VB 2 , SiC and B 4 C is the starting material, VB can be formed 2 / SiC or VB 2 / SiC / B 4 C eutectic composite ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com