Fluorescent powdery prescription with electronic beam excitation with low-operating voltage and preparation thereof

A low operating voltage, electron beam technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve problems such as poor luminous efficiency, reduced vacuum degree, and polluted field emission sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 0.6274 grams of barium oxide (BaO), 0.800 grams of europium oxide (Eu 2 o 3 ), 0.1833 grams of magnesium oxide (MgO), and 2.3173 grams of aluminum oxide (Al 2 o 3 ) (i.e. according to (Ba 0.9 Eu 0.1 )MgAl 10 o 17 The proportion of the mixture) is fully mixed, ground and mixed thoroughly with a mortar, and the uniform mixture is placed in an alumina crucible, and then the alumina crucible is placed in a high-temperature furnace and pre-sintered at 1650 ° C for 12 hours in a reducing atmosphere environment. The sintering process The heating and cooling rates were both 5°C / min. After sintering, it is ground with a mortar to make it into a powder with uniform particles, and the finished product is obtained.

Embodiment 2

[0023] 1.8947 grams of barium oxide (BaO), 0.2416 grams of europium oxide (Eu 2 o 3 ), 0.5091 grams of magnesium oxide (MgO), 7.0000 grams of aluminum oxide (Al 2 o 3 ), and 0.1263 grams of manganese carbonate (MnCO 3 ) (i.e. according to (Ba 0.9 Eu 0.1 )(Mg 0.92 mn 0.08 ) Al 10 o 17 The proportion of the mixture) is fully mixed, ground and mixed thoroughly with a mortar, and the uniform mixture is placed in an alumina crucible, and then the alumina crucible is placed in a high-temperature furnace and pre-sintered at 1650 ° C for 12 hours in a reducing atmosphere environment. The sintering process The heating and cooling rates were both 5°C / min. After the sintering is completed, it is ground with a mortar to make it into a powder with uniform particles, and the finished product is obtained.

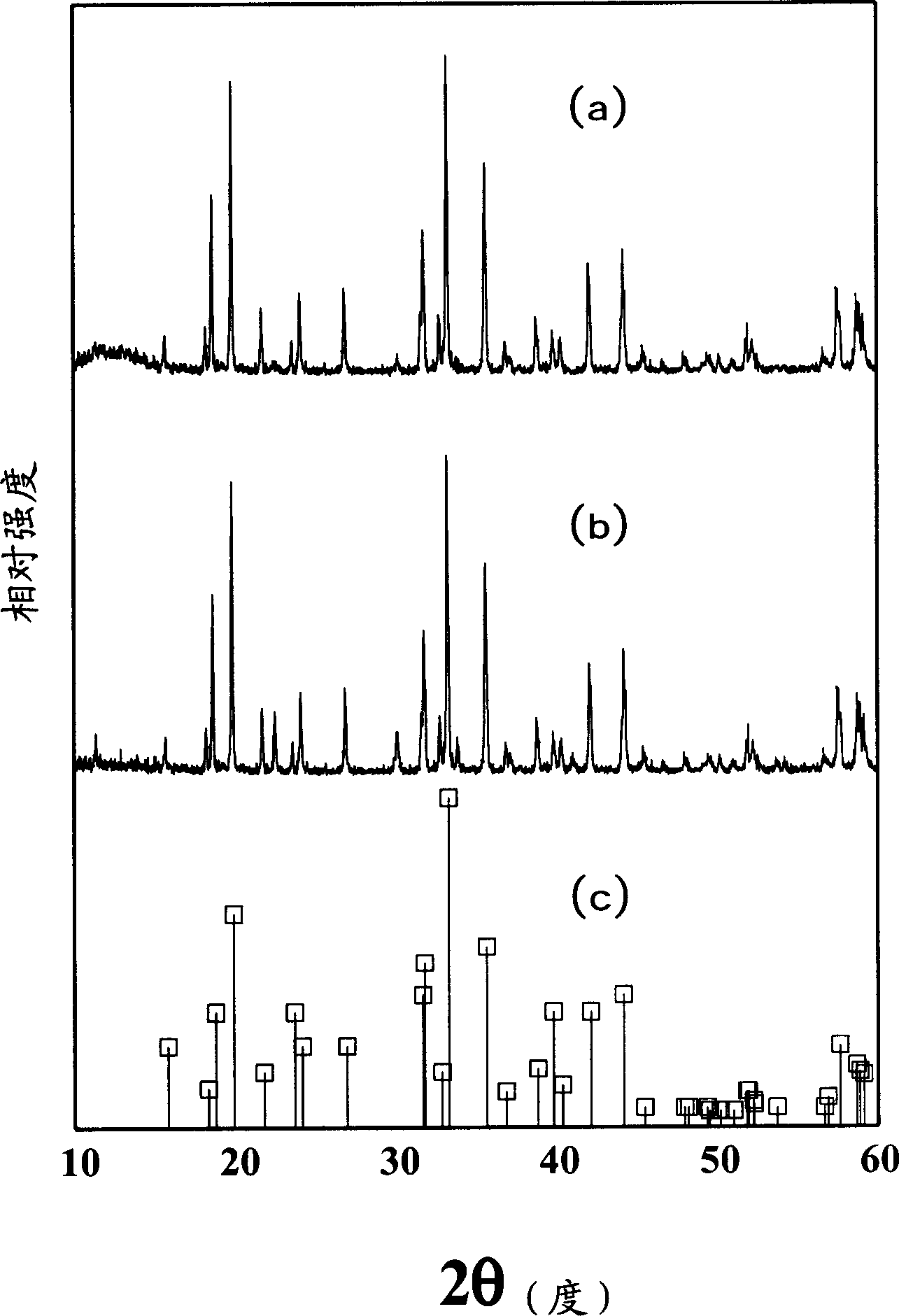

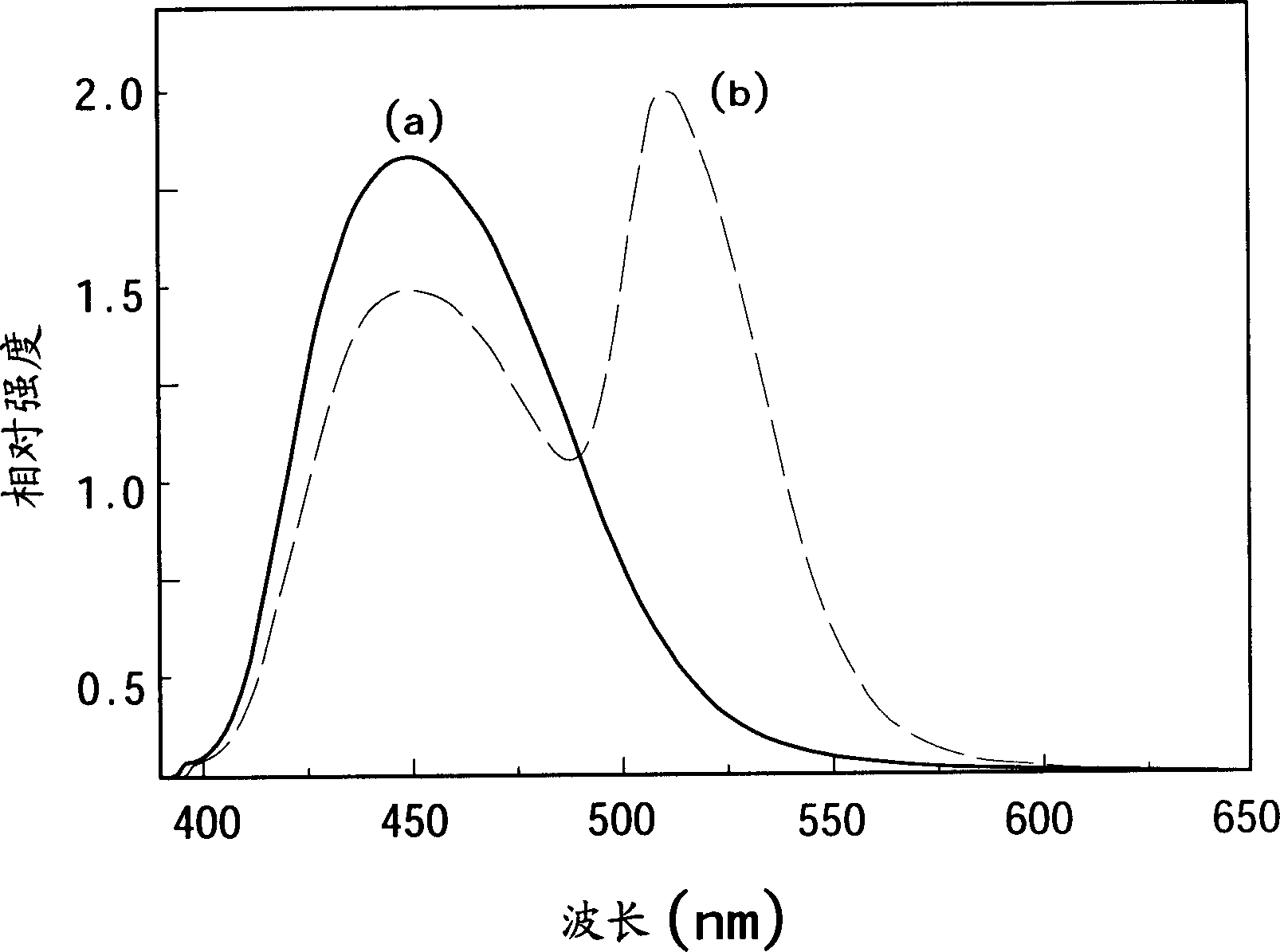

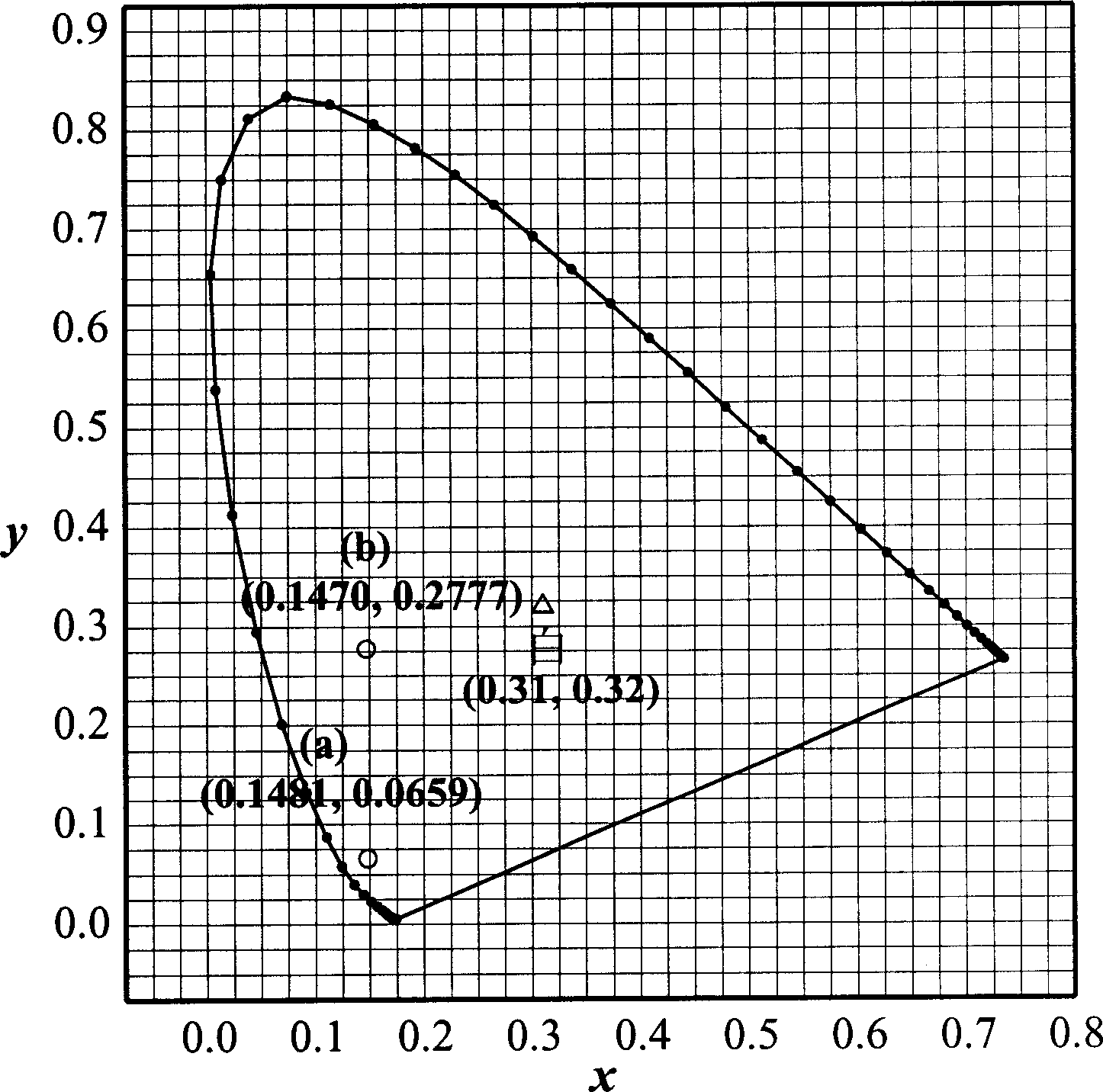

[0024] (Ba) prepared according to the embodiments of the present invention 1-x Eu x )MgAl 10 o 17 (x=0.1) and (Ba 1-x Eu x )(Mg 1-y mn y ) Al 10 o 17 (x=0.1, y=0.08) s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap