Variable geometry turbine

A geometry, turbine technology, used in engine manufacturing, combustion engines, gas turbine installations, etc., to solve problems such as overshoot, increased boost pressure, and high intake manifold pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

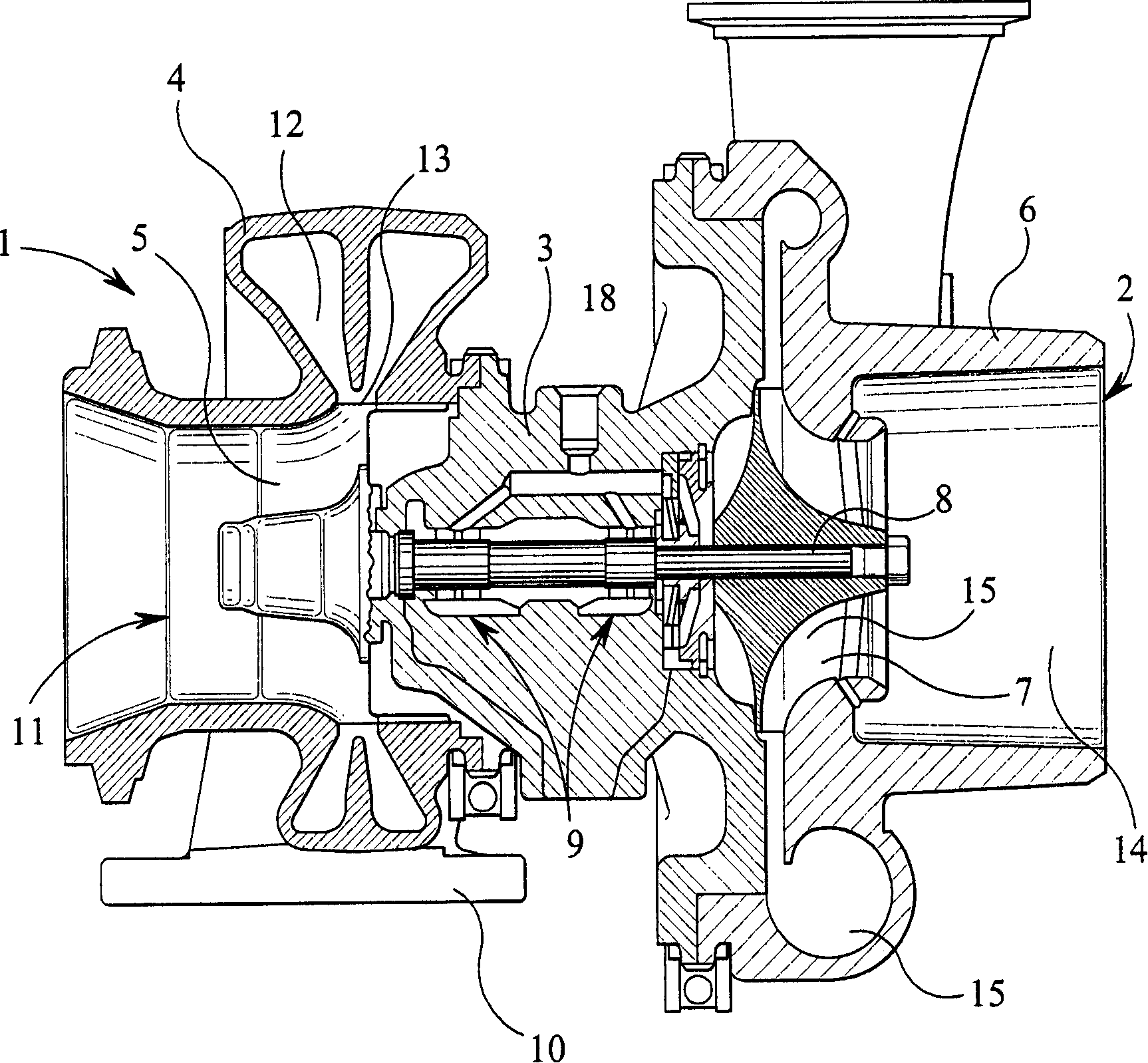

[0025] figure 1 is an axial sectional view of a typical turbocharger with a fixed geometry turbine showing the basic parts of the turbocharger. The turbocharger comprises a turbine 1 connected via a central bearing housing 3 to a compressor 2 . The turbine 1 comprises a turbine housing 4 in which a turbine wheel 5 is accommodated. Similarly, the compressor 2 comprises a compressor housing 6 in which a compressor wheel 7 is placed. The turbine wheel 5 and the compressor wheel 7 are mounted on both ends of a conventional turbine shaft 8 supported by a bearing assembly 9 inside the bearing housing 3 .

[0026] The turbine housing 4 has an exhaust gas inlet 10 and an exhaust gas outlet 11 . Inlet 10 directs incoming exhaust gas into an annular inlet chamber, volute 12 , which surrounds turbine wheel 5 and communicates therewith through a radially extending annular inlet passage 13 . The rotation of the turbine wheel 5 drives the rotation of the compressor wheel 7, which draws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com