Hybrid optical element and photodetector device

A technology of light-receiving elements and optical elements, which is applied in the direction of integrating optical head devices, beam guiding devices, electrical components, etc., can solve the problems of increasing manufacturing costs and increasing overall size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

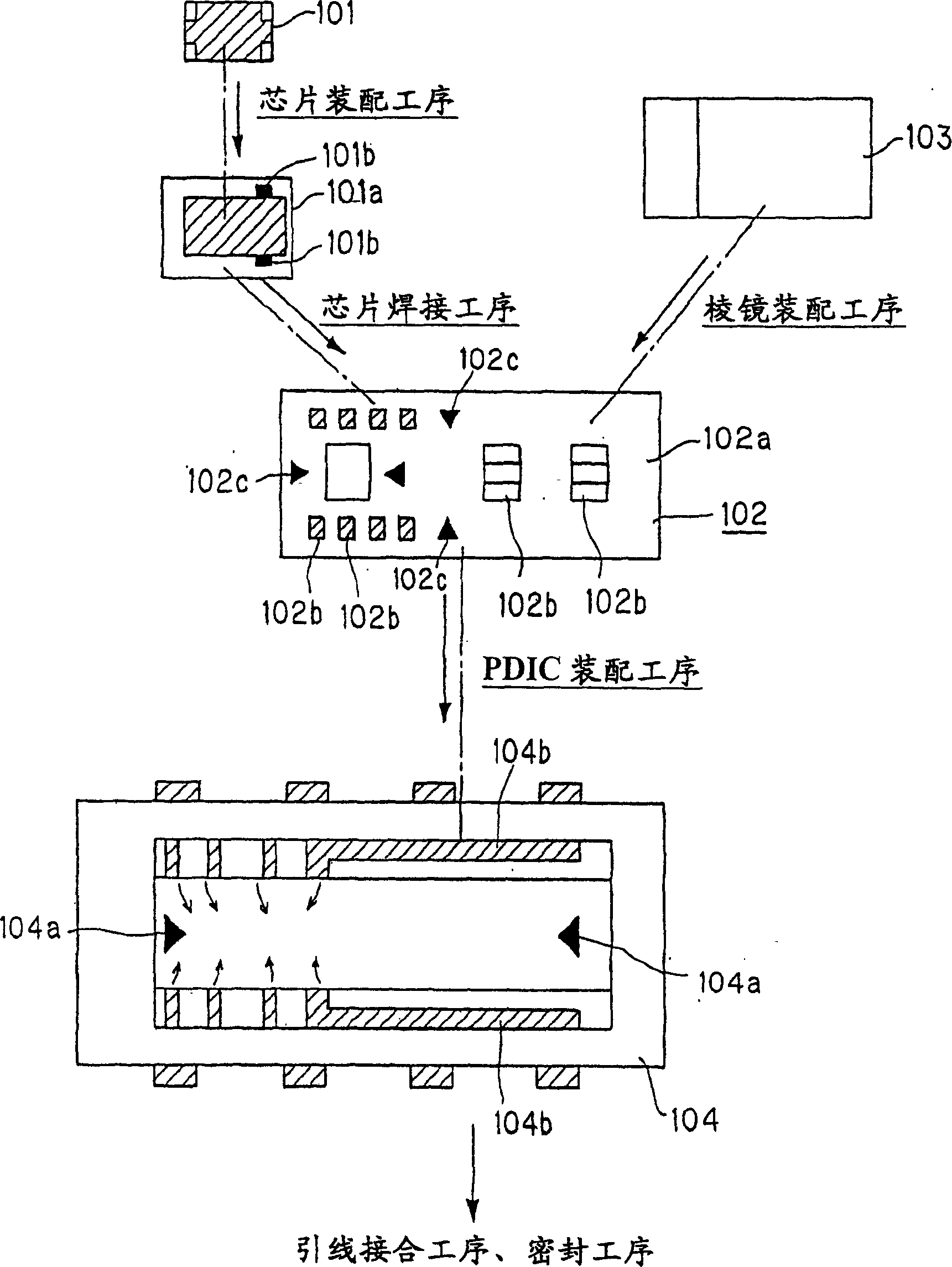

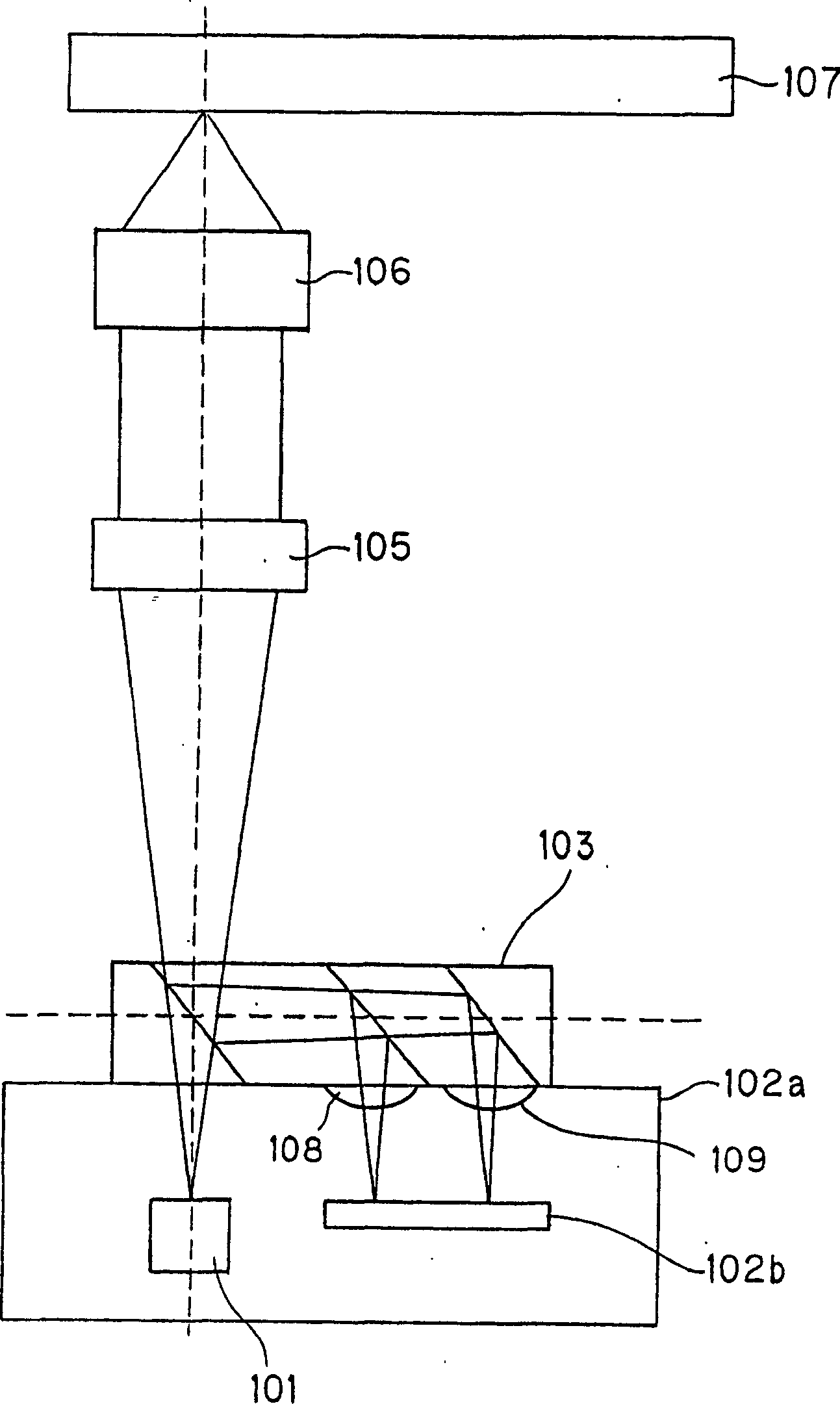

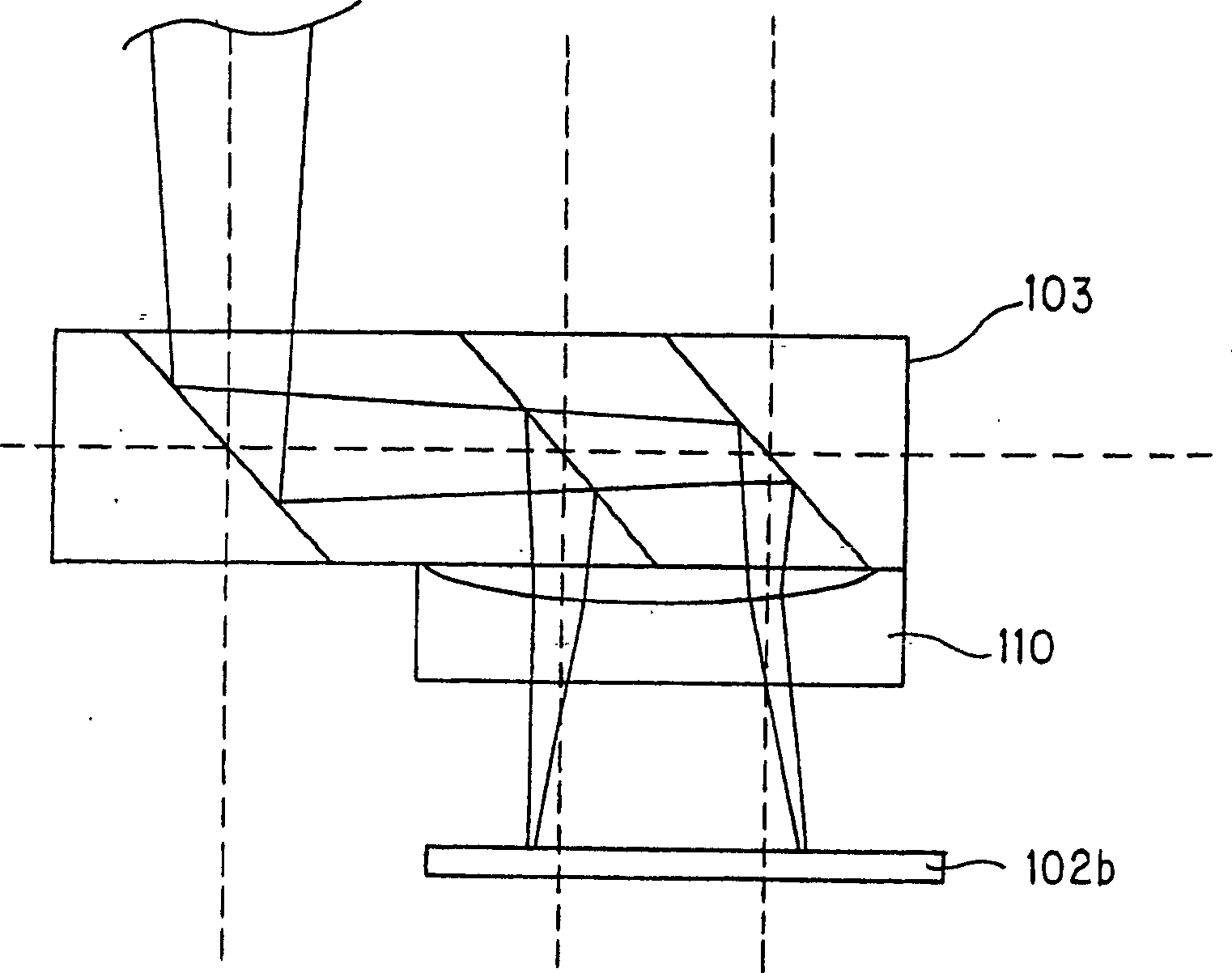

[0075] Embodiments of the present invention will be described below with reference to the drawings.

[0076] As shown in Figure 9, in the composite optical element and light receiving element device of the present invention, be provided with: be installed on one side of substrate 1 at least one optical element 2 that comprises lens, prism and diffractive element and be installed on substrate 1 On the other side, the semiconductor laser 3 and the light receiving element 4 as the light emitting element. Between the substrate 1 and the light receiving element 4, a relay substrate 5 as an intermediate member is provided. The manufacturing method of the composite optical element of this invention is a method for manufacturing such a composite optical element.

[0077] A first through hole 8 is formed on the substrate 1 to transmit the light beam emitted from the semiconductor laser 3 to one side of the substrate 1 . The substrate 1 is formed with a second through hole 9 through w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com