Composite casing of travelling-wave tube

A composite tube shell and traveling wave tube technology, which is applied in the manufacture of tube shells/containers, ships or lead-in wires of transit-time electron tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

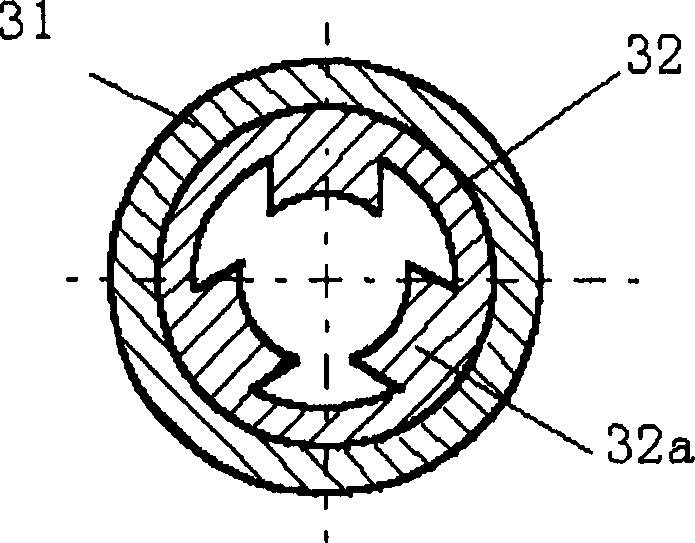

[0023] The novel composite shell of the present invention for traveling wave tubes such as image 3 shown. The number 31 among the figure is the outer shell, and the number 32 is the inner shell. Both the outer shell 31 and the inner shell 32 are tubular, and the lengths of the two are the same. The inner wall surface of the tube shell 31 is fixedly connected to the outer peripheral surface of the inner tube shell 32 . The outer tube shell 31 is made of Monel, non-magnetic stainless steel and other materials, which not only has sufficient mechanical strength, but also ensures vacuum airtightness. The inner tube shell 32 is made of oxygen-free copper with excellent electrical conductivity, and the inner tube shell 32 can be cut into various shapes by wire cutting, for example, the inner tube shell 32 can have fins 32a. In addition, the outer shell 31 and the inner tube 32 are welded in a proper manner.

[0024] image 3 Shown is the manufacturing process of the novel compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com