Waste processing method and waste processing apparatus

A treatment method and waste technology, which is applied in the direction of oxidation treatment sludge, solid waste removal, oxidized water/sewage treatment, etc. It can solve problems such as difficult treatment, reduced solubility of inorganic substances, high maintenance and repair costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

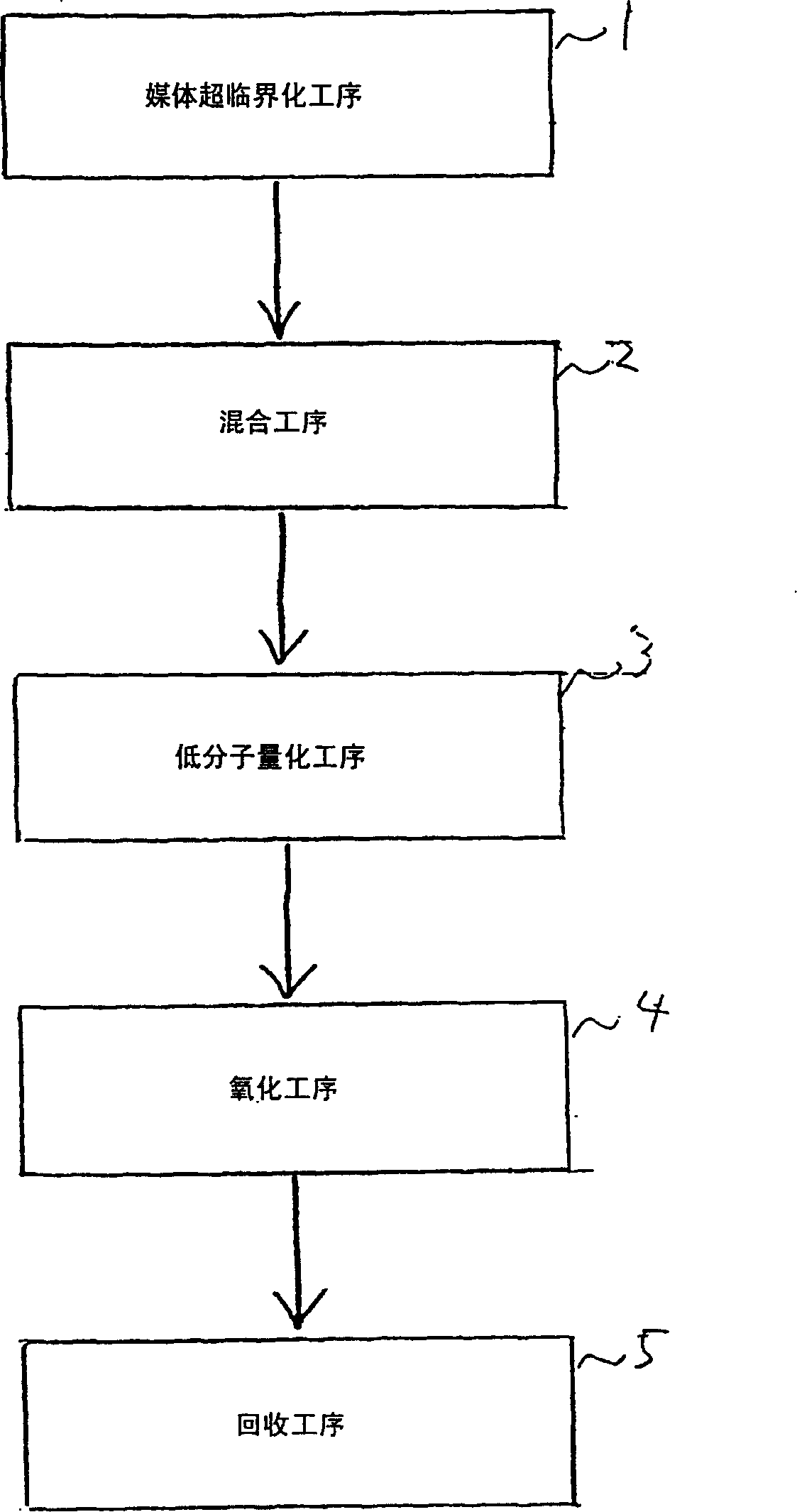

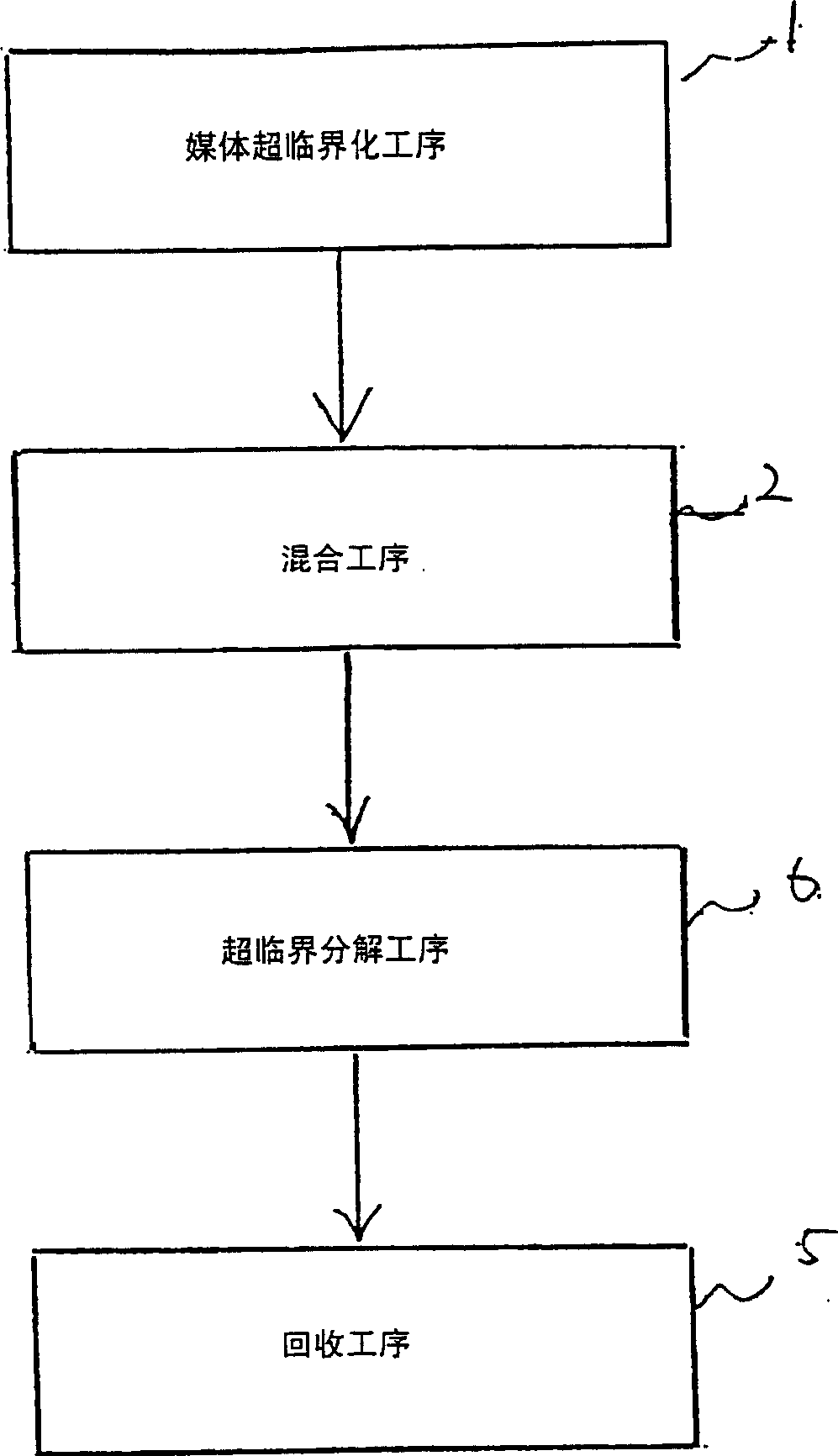

[0232] figure 1 A process diagram showing Embodiment 1 of the present invention. figure 2 It is a process diagram of a conventional example.

[0233] Such as figure 2 As shown, in the conventional method, water as a medium is brought into a supercritical state in the medium supercriticalization step 1 . In the mixing step 2, sulfate-containing organic waste is added to the supercritical water. In the supercritical decomposition step 6, the resulting mixture is kept together with an oxidizing agent at a high temperature and pressure exceeding the critical point of water for a predetermined time. Organic waste containing sulfate is oxidatively decomposed in supercritical water.

[0234] The generated decomposed gas and decomposed liquid, and inorganic substances (oxides, etc.) such as sulfate contained in the organic waste are sent to the recovery process 5, and receive treatment such as recovery and solidification of harmful substances.

[0235] On the other hand, in the...

Embodiment 2

[0268] In the method of embodiment 2, in figure 2 In the existing medium supercriticalization step 1 shown, the hydrogen ion is 10 for 1 kg of water -4 The inorganic acid is added in a mole or more to bring the solution into a supercritical state, and is used as a supercritical medium in the subsequent steps.

[0269] According to the research of Smith et al., the metal elements in nitric acid waste liquid are hydrolyzed as shown in V formula under high temperature and high pressure, and then thermally decomposed as shown in VI formula, and finally become oxides.

[0270] Nitric acid generated in formula V generates oxygen after thermal decomposition, so it is easy to form oxides.

[0271] ...Type V

[0272] ...formula VI

[0273] To prevent such hydrolysis, acid must be added, shifting the equilibrium of formula V to the left.

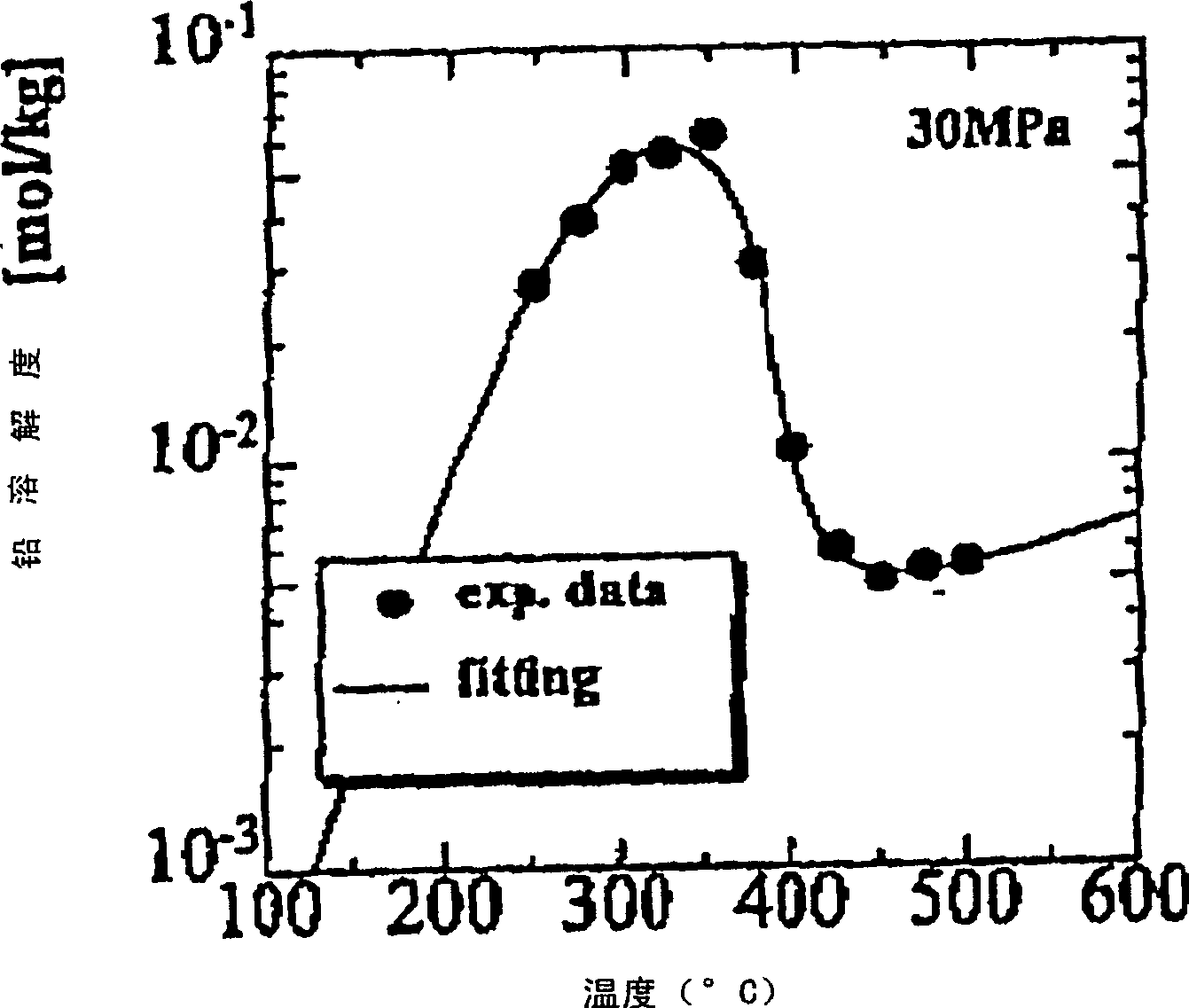

[0274] The concentration of hydrogen ions in water is closely related to the ion product of water. Figure 4 Ind...

Embodiment 3

[0306] Image 6 is a schematic diagram showing the waste treatment device of this embodiment.

[0307] The waste treatment device of this embodiment is equipped with: a reactor 11 for treating organic waste in a supercritical state of water, an organic waste supply device 12 for feeding organic waste into the reactor 11, and supplying water as a medium to the reactor. A water supply device 13 at 11, an oxidation reactor 14 for oxidizing low-molecular-weight organic substances produced in the reactor 11, an oxidant supply device 15 for supplying an oxidizing agent to the oxidation reactor 14, and a recovery device 30 for recovering a product of the oxidation reactor 14.

[0308] The recovery unit 30 is equipped with a gas-liquid separator 33 , a gas treatment unit 34 , and a liquid treatment unit 40 .

[0309] The liquid treatment device 40 has a drier 45 and a solidifier 46 for drying and solidifying the liquid sludge.

[0310] In this embodiment, the reactor 11 and the oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com