Powdery, cross-linked absorbent polymers method for the production thereof and their use

A polymer and absorbent technology, applied in the field of powdery cross-linked polymers, can solve the problems of a large amount of organic solvents and the inability to carry out industrial production at a cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

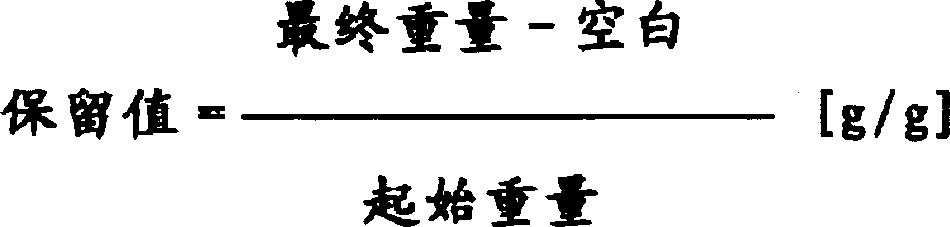

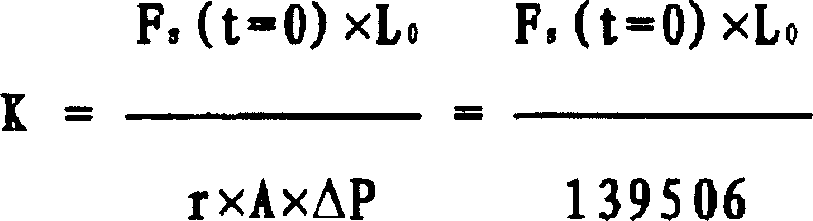

Image

Examples

Embodiment 1

[0079] Polyacrylic acid obtained by solution polymerization, crosslinked with 0.7% by weight of polyethylene glycol diacrylate relative to acrylic acid and neutralized in the form of its sodium salt at 70 mol %, was dried, ground and sieved to obtain a particle size of 150 - 850 μm powder (powder A). 100 g of powder A were mixed with a solution of 1 g of 1,3-dioxolan-2-one, 3 g of water and 0.5 g of aluminum sulfate octadecahydrate under vigorous stirring and subsequently heated in an oven to 180° C. for 30 minutes.

[0080] For comparison, 100 g of powder A were mixed with a solution of 1 g of 1,3-dioxolan-2-one and 3 g of water and subsequently heated in an oven for 30 minutes to 180° C. (comparative example 1 according to DE 4020 780).

[0081] For further comparison, 100 g of powder A were mixed with a solution of 3 g of water and 0.5 g of aluminum sulfate octadecahydrate and then heated in an oven to 180° C. for 30 minutes (comparative example 2).

[0082] Product TB AAP...

Embodiment 2-6

[0089] Five kinds of powdered polyacrylic acid (powder B, C, D, E and F, each 100 g) was dried and ground and sieved to 150-850 μm and mixed with a solution of 1 g 1,3-dioxolan-2-one, 3 g water and 0.5 g aluminum sulfate octadecahydrate under vigorous stirring and then in Heat in an oven for 30 minutes to 180°C.

[0090] Product TB Crosslinker AAP 0.7 SFC TB+SFC

[0091] [g / g] Wt.-% / AA * [g / g] [10 -7 cm 3 s / g]

[0092] Powder B 30 1.1 12 0 30

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com