Single plate double side stator type linear motor oil pumping machine

A technology of linear motors and pumping units, which is applied in the fields of mining fluids, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of easily damaged mover guide wheels, waste of man-hours, unsafety, etc., and achieves convenient maintenance and replacement , Simplify the mechanical structure, optimize the effect of the force structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

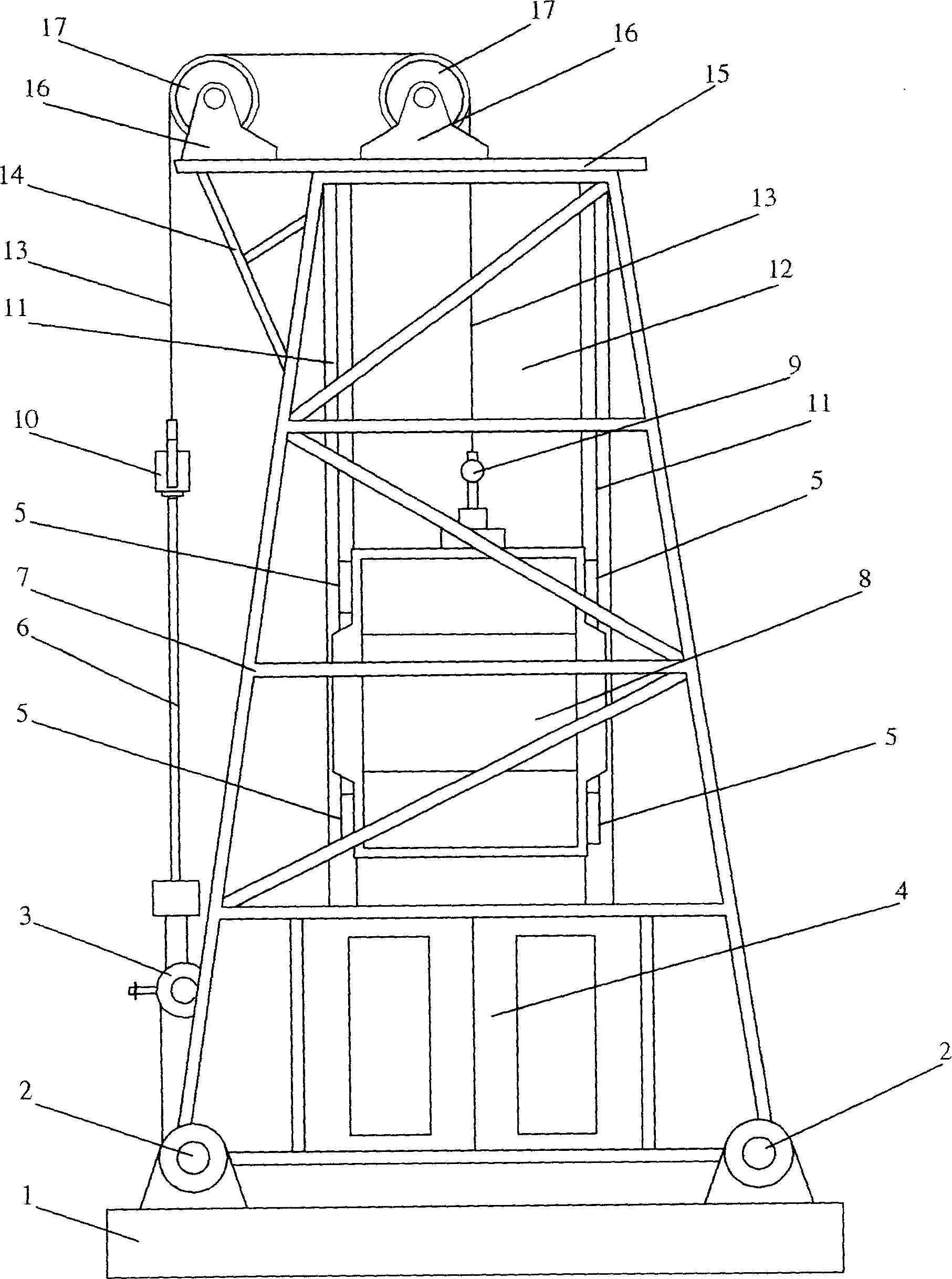

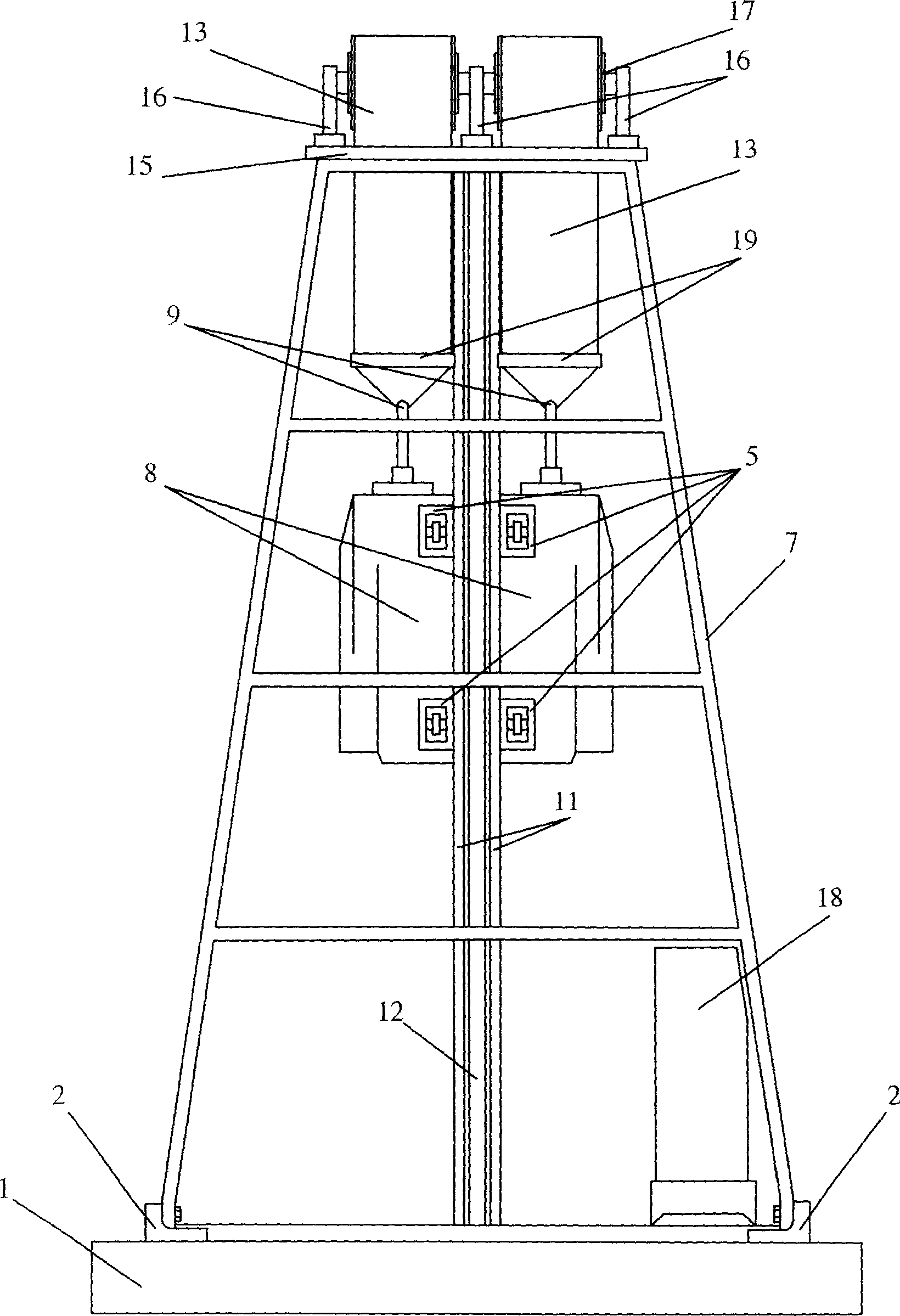

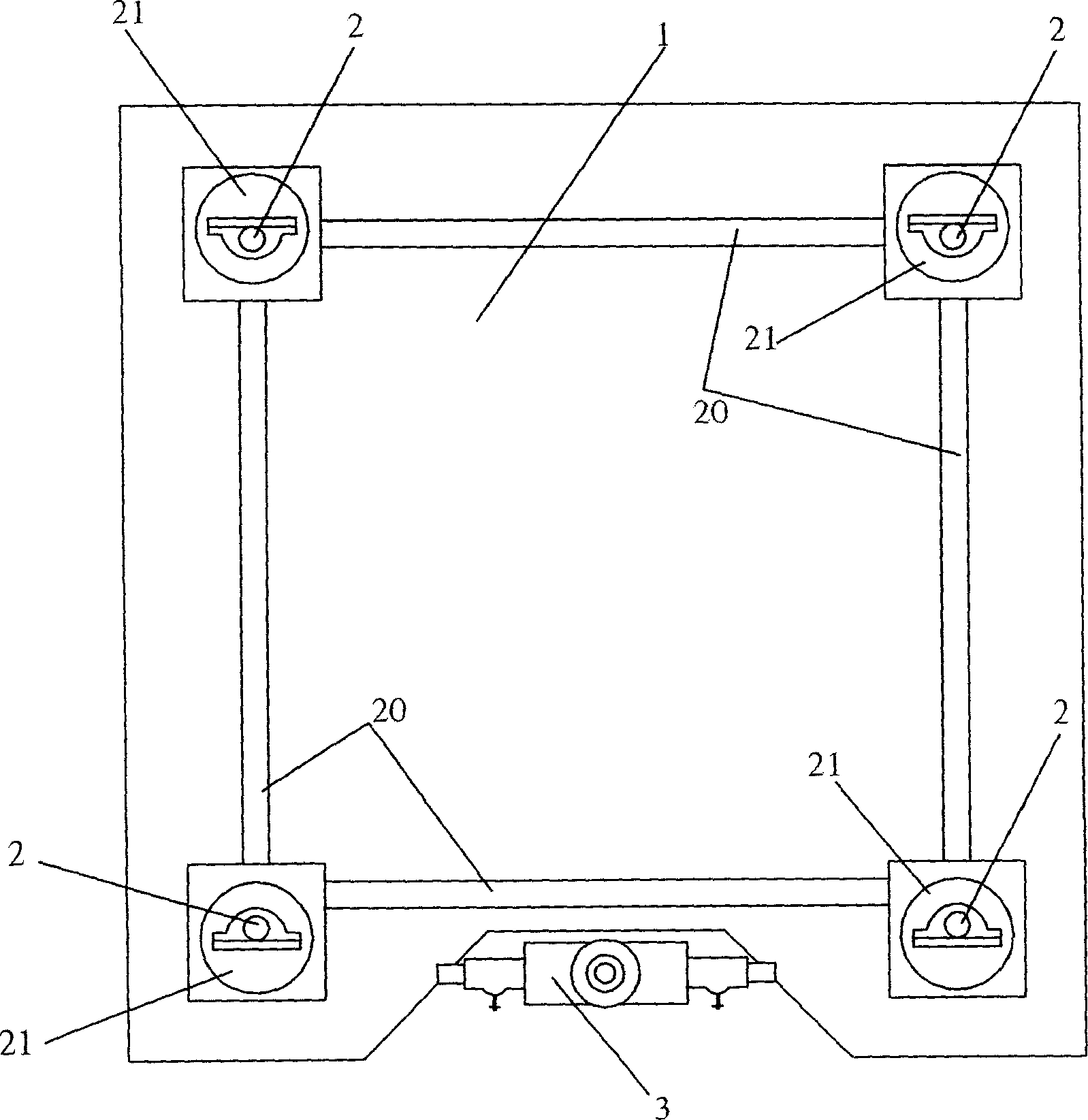

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1-3 As shown, the single-plate double-sided stator linear motor pumping unit of the present invention is mainly composed of a pumping unit foundation 1, a frame fixing mechanism 2, a safety door 4 for maintenance, a mover slider 5, a main frame 7, and a linear motor mover 8. Mover broadband connector 9, rope hanger 10, linear bearing mover guide rail 11, single-plate double-sided motor stator 12, high-strength flexible connection broadband 13, top plate bracket 14, top plate 15, guide wheel support 16, Guide wheel set 17, intelligent control system 18, broadband convergence fixture 19, foundation reinforcing rib 20, rotary base frame base 21 is formed. The mover 8 of the linear motor reciprocates up and down along the linear bearing mover guide rail 11 relative to the single-plate double-sided motor stator 12, and its force passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com