Accumulation phase-change material, and defrosting system of accumulation type air-source heat pump of using the material

An air source heat pump and phase change material technology, applied in heat exchange materials, lighting and heating equipment, damage protection and other directions, can solve the problems of large energy loss, poor operation effect, poor defrosting reliability, etc. The effect of heat transfer temperature difference, increase of condensation temperature and reduction of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

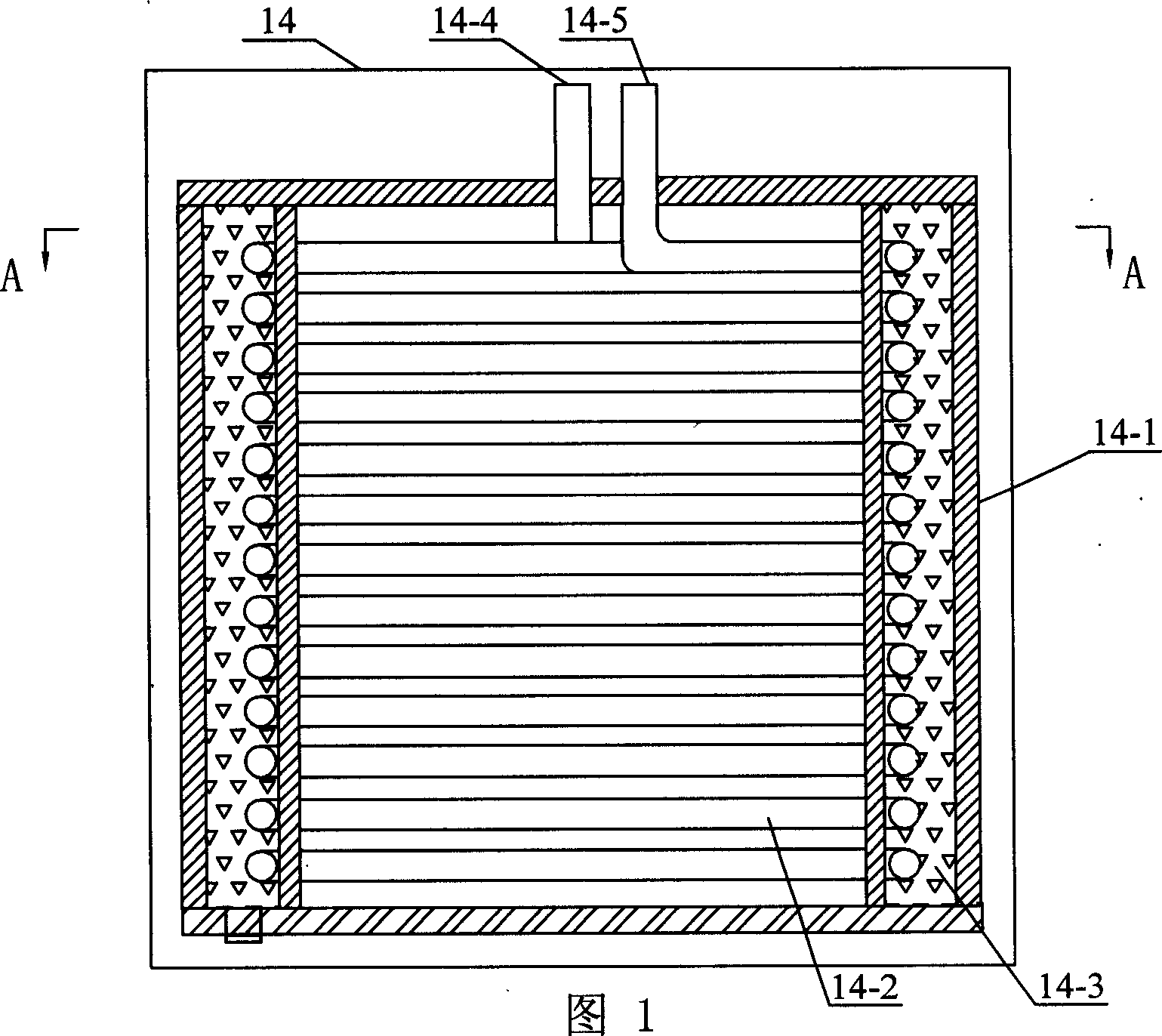

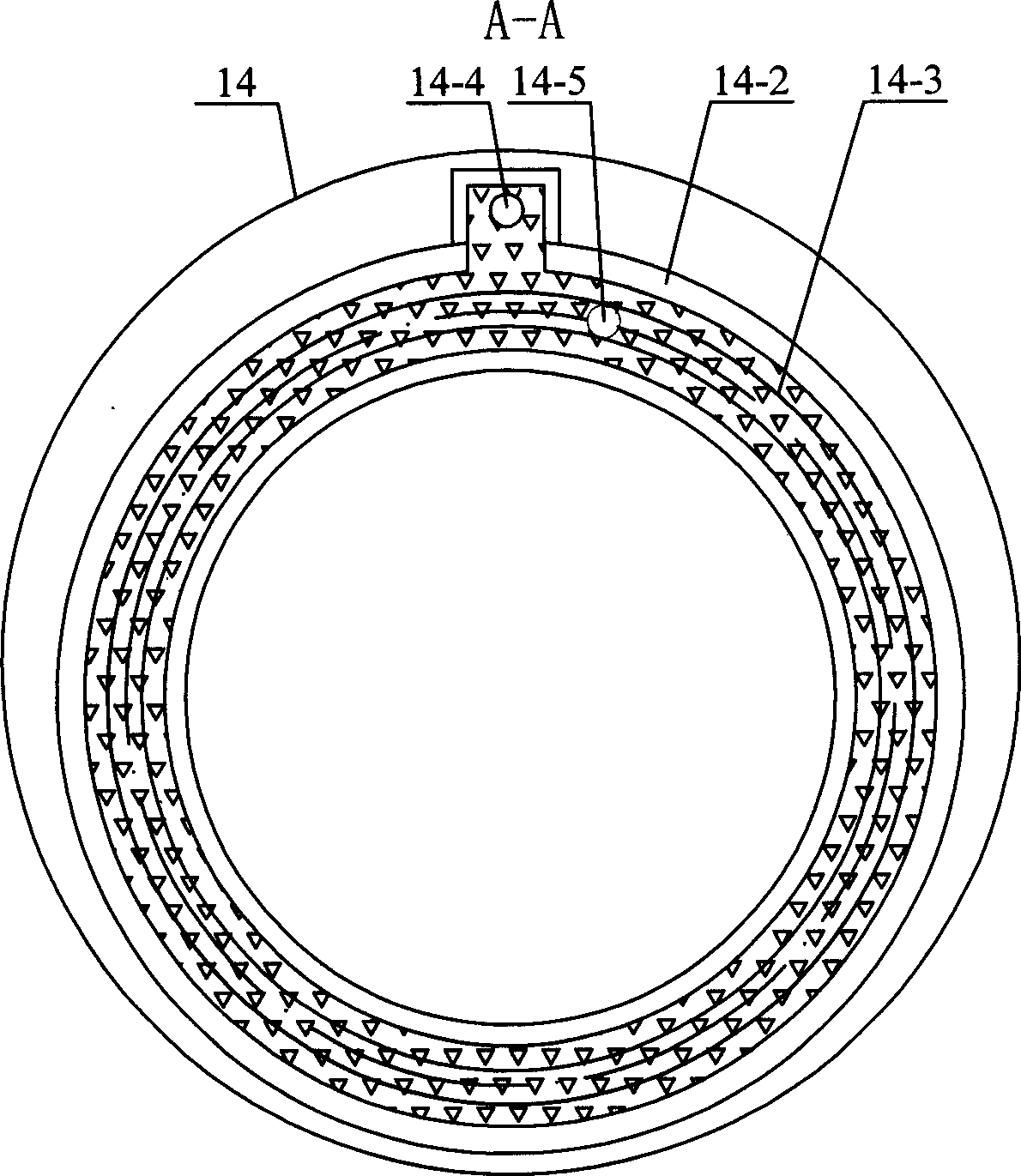

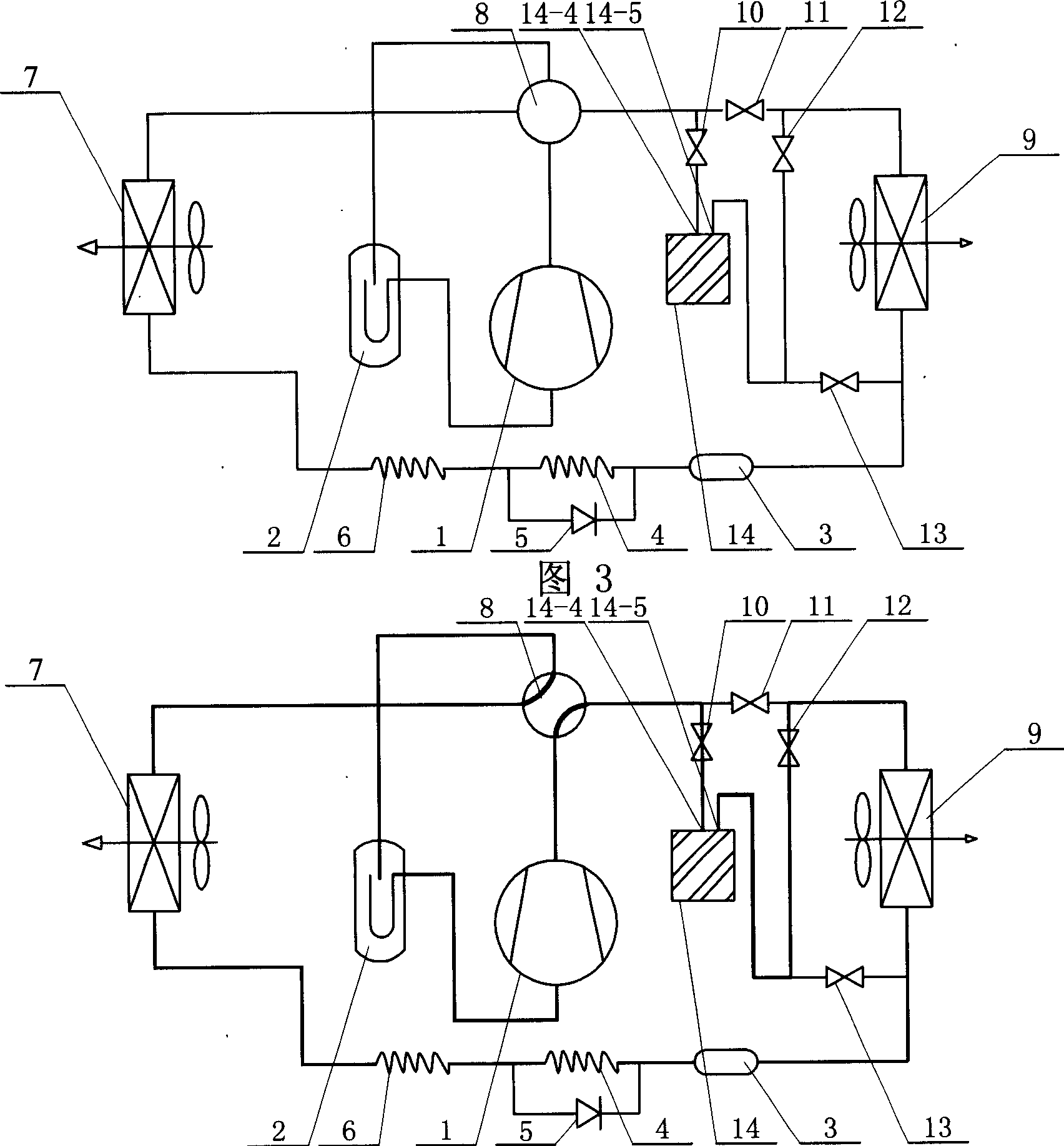

[0010] Specific implementation mode one: in conjunction with Fig. 1, figure 2 ,image 3, Figure 4 To illustrate this embodiment, the chemical composition of the energy storage phase change material is composed of CaCl 2 ·6H 2 O, nucleating agent composition, CaCl 2 ·6H 2 The mass percent of O is 95~99%, and the mass percent of nucleating agent is 1~5%; The chemical composition of described nucleating agent is by Ba(OH) 2 , BaSO 4 Composition: The energy-storage air source heat pump defrosting system using the above-mentioned energy-storage phase change material includes a compressor 1, a gas-liquid separator 2, a dry filter 3, a first capillary 4, a one-way valve 5, a second capillary 6, Outdoor heat exchanger 7, four-way reversing valve 8, indoor heat exchanger 9; the output port of compressor 1 is connected to the first input and output port of four-way reversing valve 8, and the input port of compressor 1 is The port is connected to the output port of the gas-liquid s...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the CaCl 2 ·6H 2 The mass percent of O is 96%, and the mass percent of the nucleating agent is 4%. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the CaCl 2 ·6H 2 The mass percent of O is 98%, and the mass percent of the nucleating agent is 2%. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com