Constant flow pump and its manufacturing method

A technology of quantitative pump and flow direction, which can be used in injection devices, pumps, liquid distribution, etc., and can solve problems such as increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

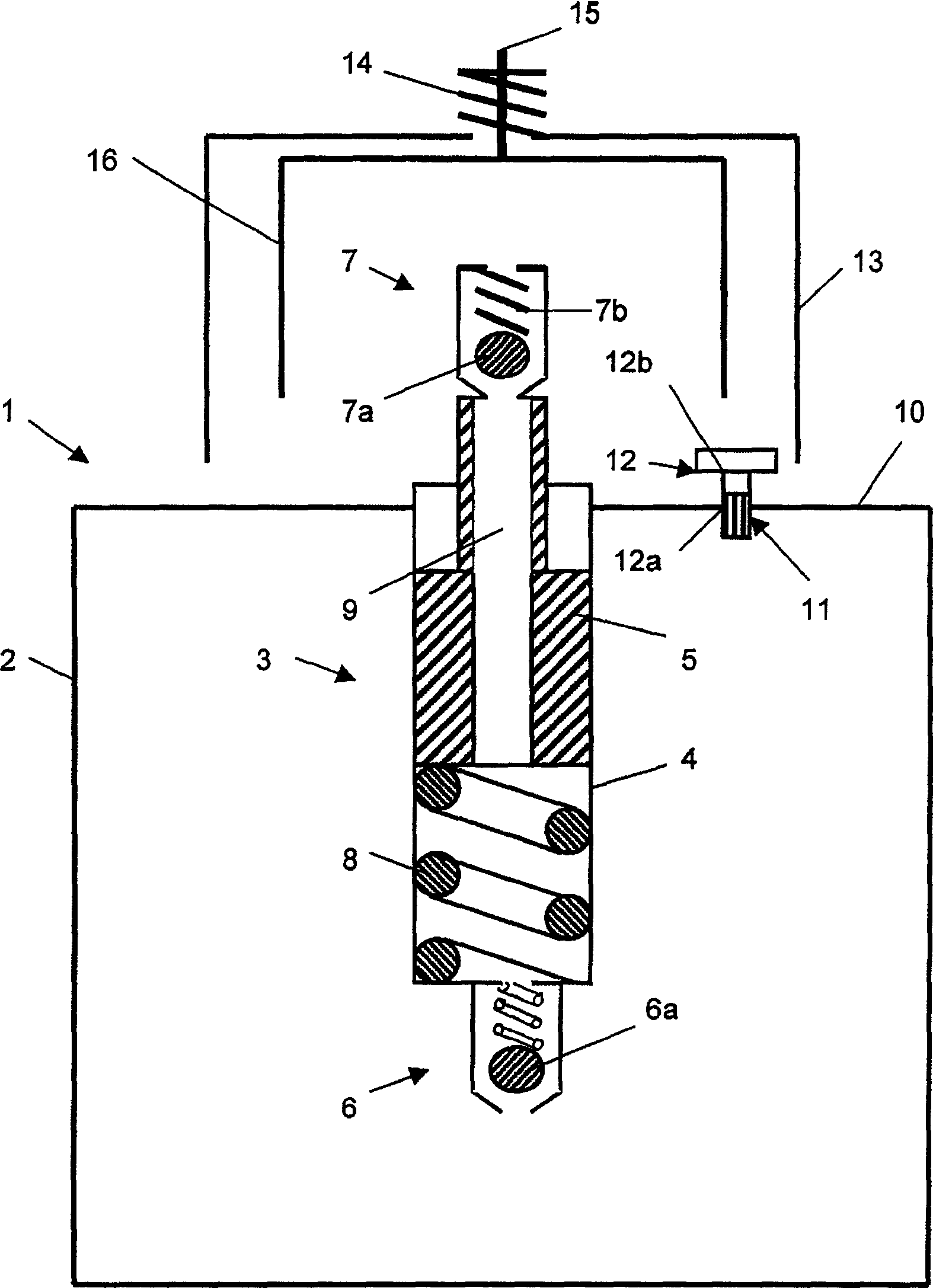

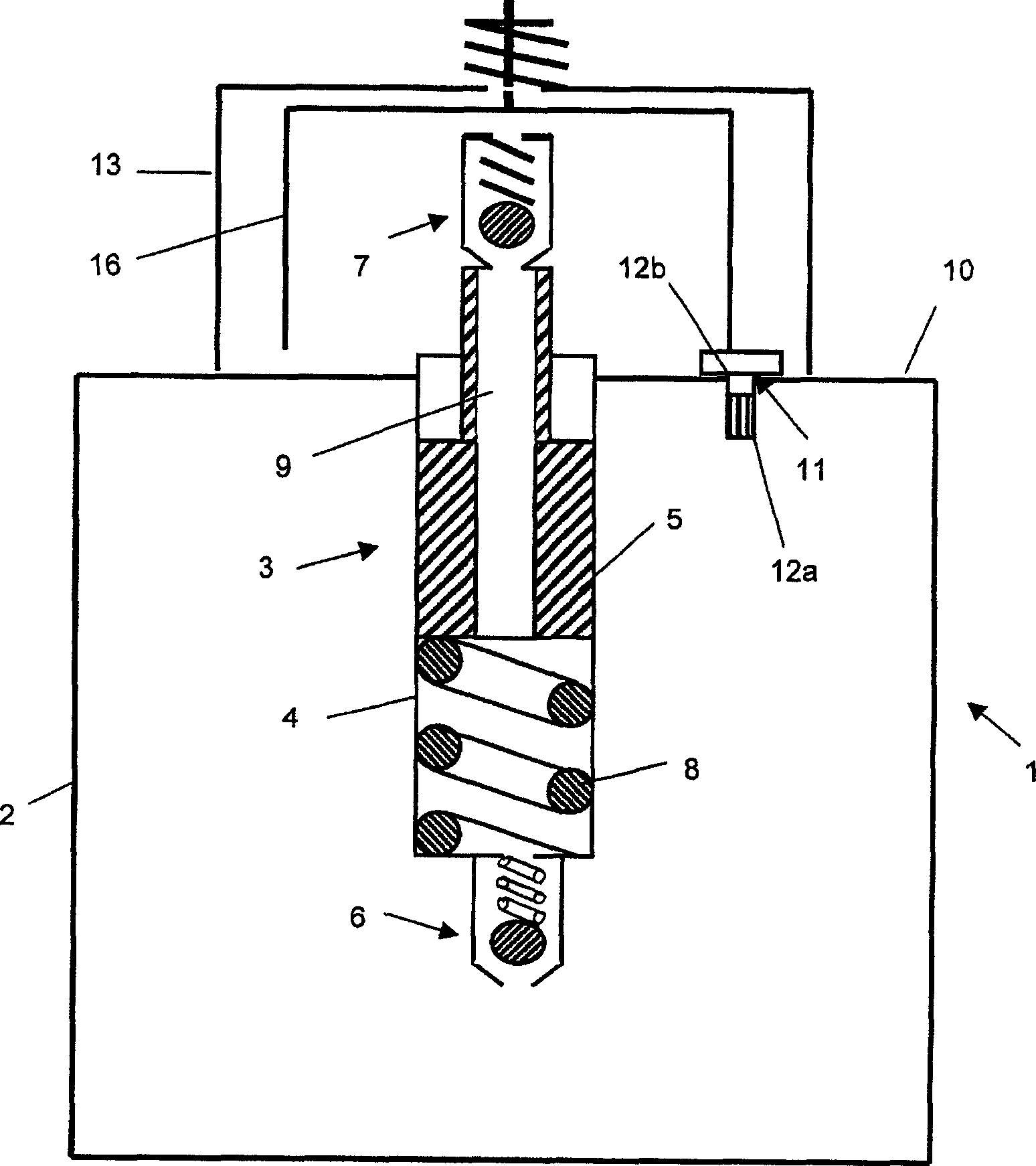

[0031] figure 1 and 2 The dosing pump device 1 shown in FIG. 1 has a container 2 that can be filled with a fluid, for example a liquid pharmaceutical or cosmetic product, and is formed by a collapsible bag. The container 2 is connected in a sealing manner to a pump 3 which, in the embodiment shown, comprises a pressure chamber 4 with a piston 5 sliding therein and two non-return valves 6 and 7 .

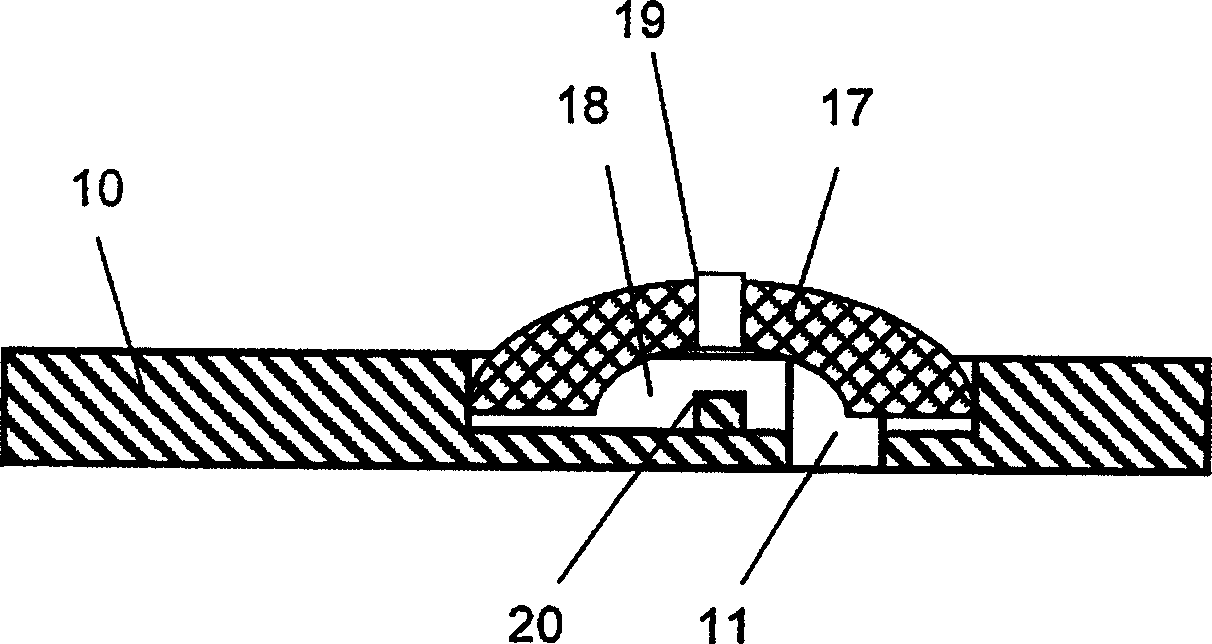

[0032] A spring 8 is arranged in the pressure chamber 4 to act upwardly on the piston 5 in the figure. The piston 5 has a central through-opening 9 through which fluid is drawn from the container 2 into the surroundings. For this purpose, the first non-return valve 6 is connected in such a way that when the spherical valve element 6 a is lifted from its valve seat due to the low pressure in the pressure chamber 4 , it allows a discharge from the container 2 to the flow in the pressure chamber 4. However, the flow in the opposite direction from the pressure chamber 4 into the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com