Plan display screen testing device

A technology of inspection device and display screen, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of increasing the weight of supporting stone materials, reducing the service life of stone platforms, and troublesome processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments will be described in detail with reference to the accompanying drawings.

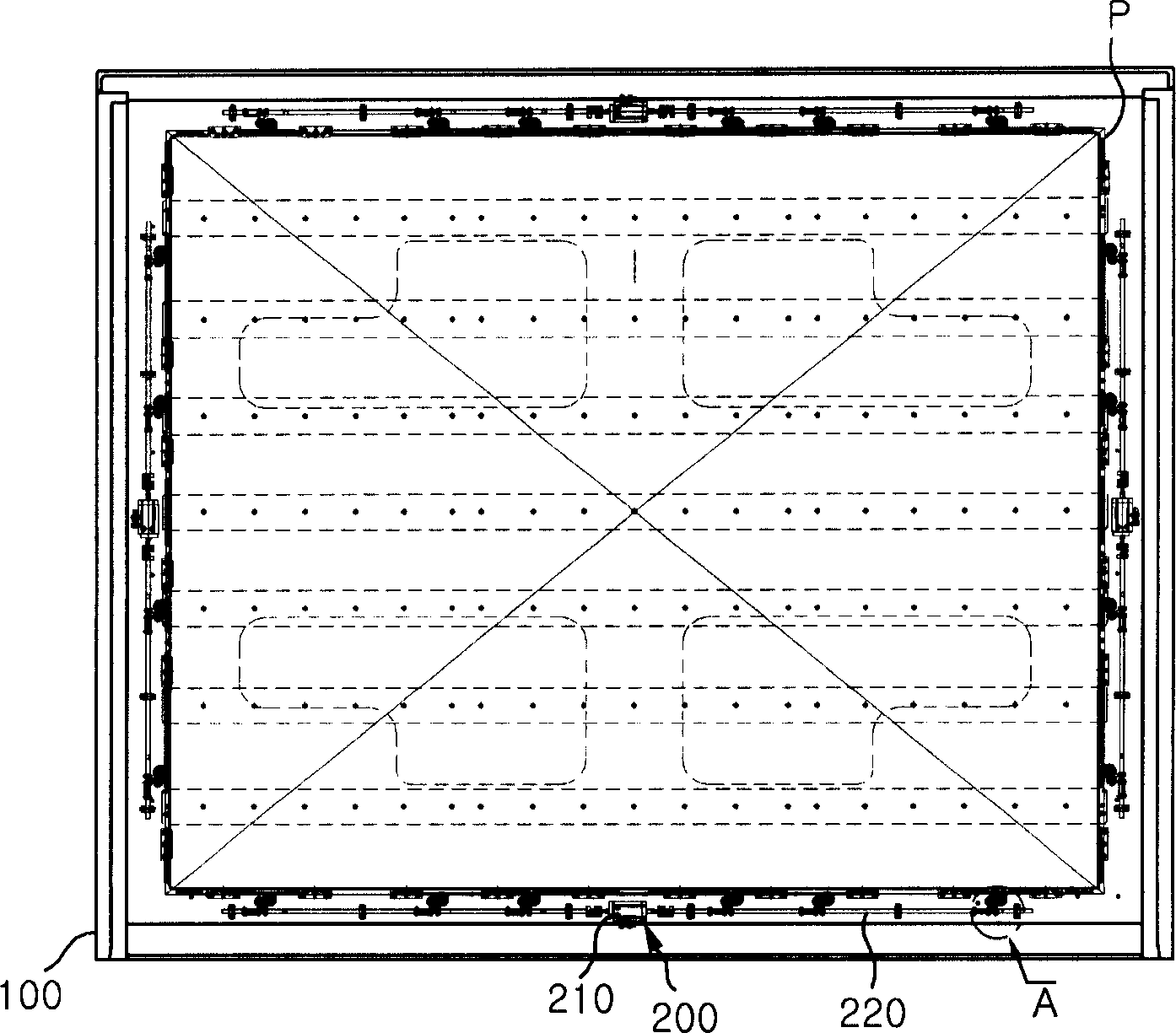

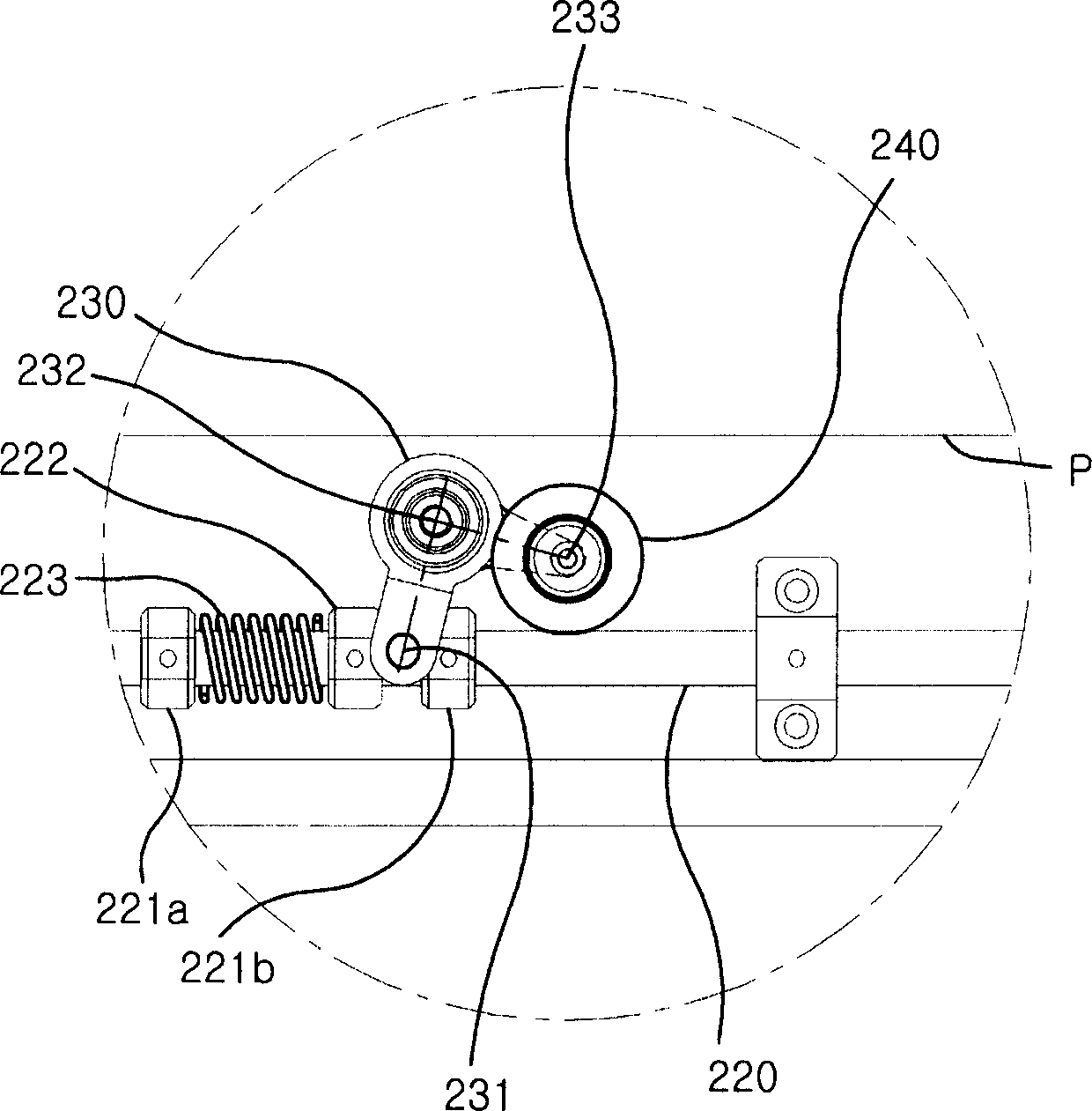

[0043] Figure 6 is a top view of the inspection device according to the first embodiment of the present invention, Figure 7 is an enlarged view of the main part of the inspection device, which shows Figure 6 The first and second calibration devices shown, Figure 8 for Figure 6 Side view of the third calibration setup shown.

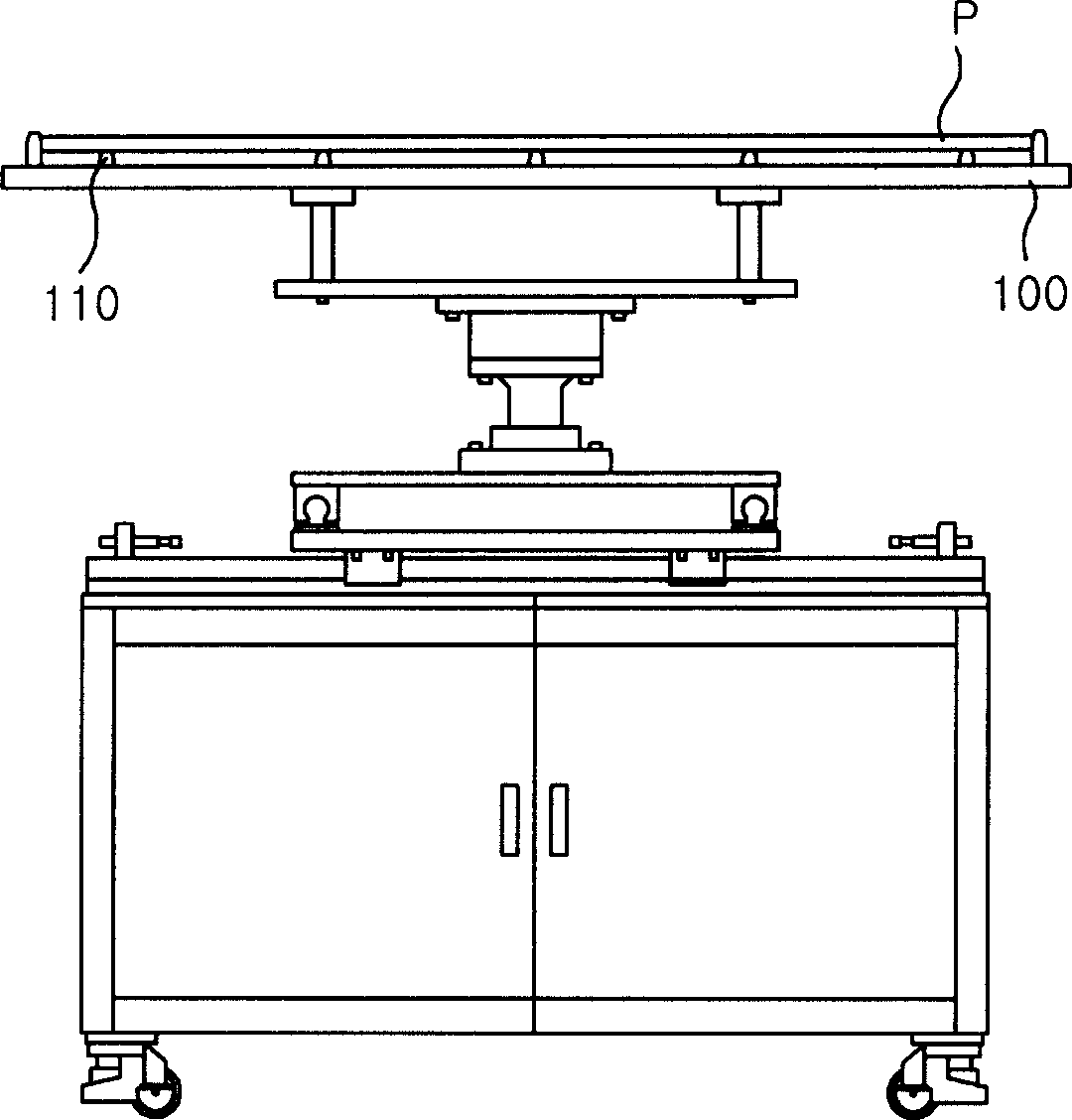

[0044] refer to Figure 6 , the inspection device of the present invention is provided with a platform 10 on which a display screen of width W×length L can be placed, and a first calibration device 20a and 20b and a second calibration device 20a and 20b are arranged on the front, rear, left and right sides of the platform 10. Devices 20c and 20d, which calibrate the display screen P by applying pressure to the sides of the display screen. The inspection device of the present invention is also provided with the third calibration d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com