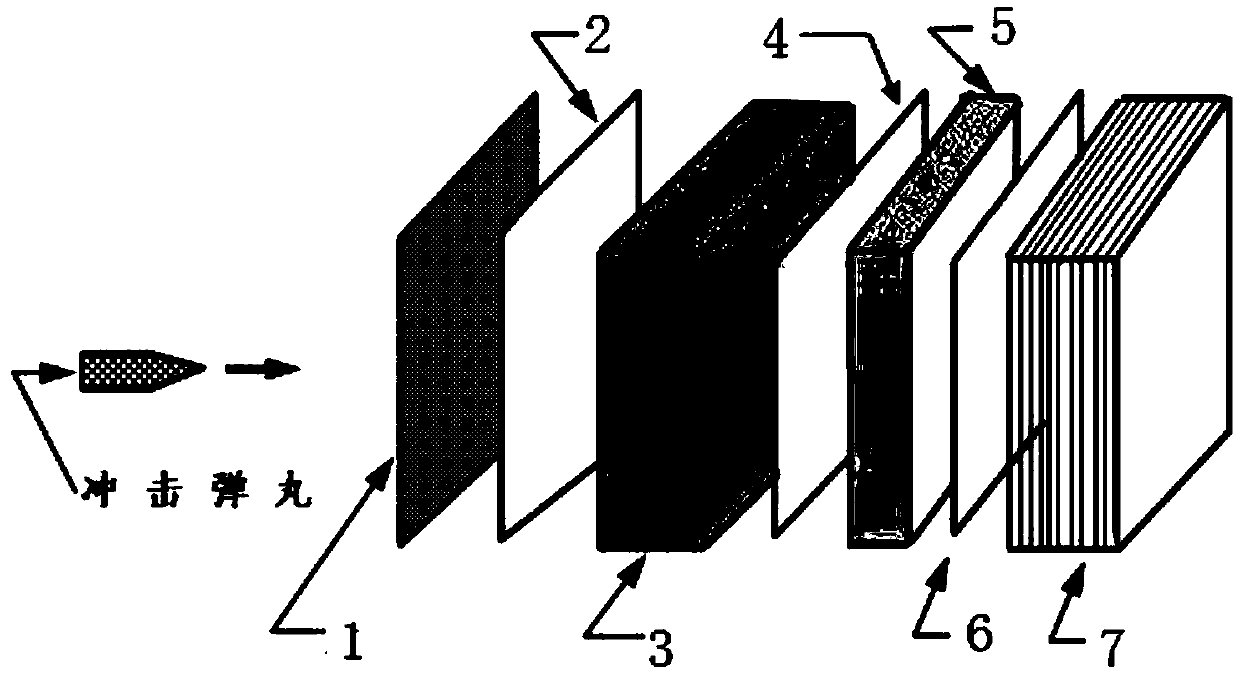

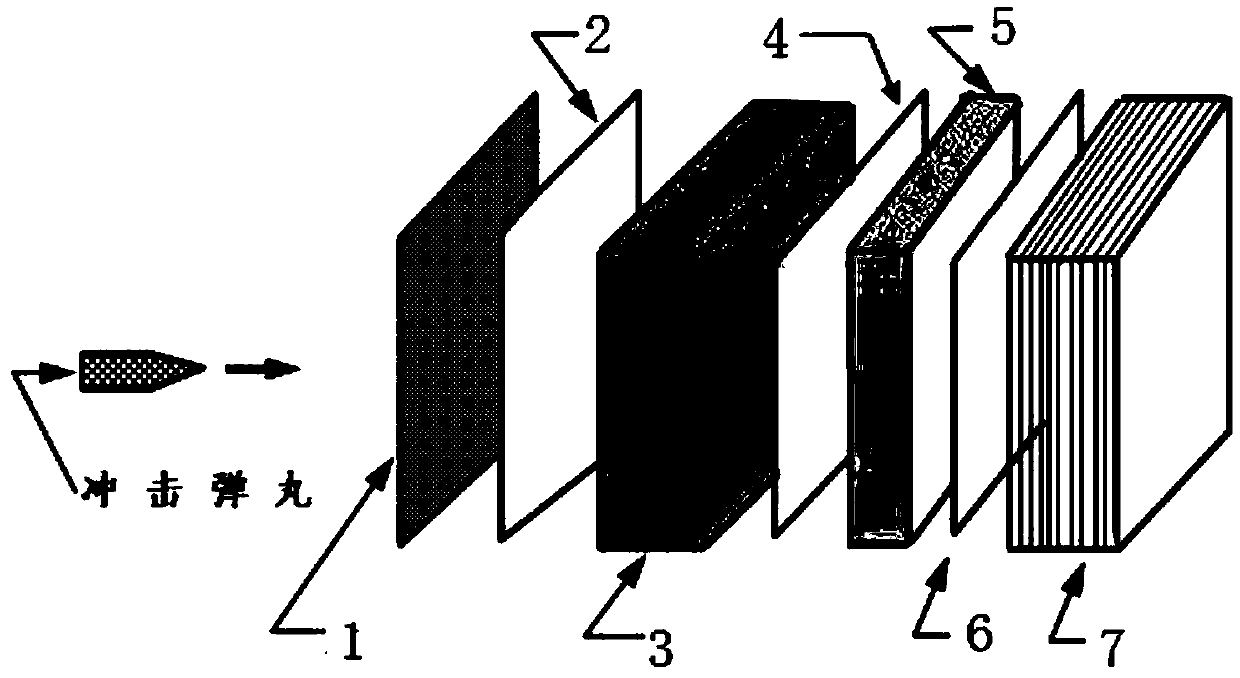

Basalt composite bulletproof plate with high impact resistance

A technology of bulletproof board and basalt, which is applied to the structure of protective clothing, protective equipment, armor plates, etc., can solve the problems of large human injuries and achieve the effects of reducing secondary damage, good heat insulation, and no melting or dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The size specification (length×width×height) of the basalt composite bulletproof plate is 300mm×300mm×13.3mm, and the total thickness of the composite bulletproof plate is 13.3mm.

[0094] Wherein, the thickness of the crack arresting layer is 0.3 mm, and it is made of aramid fiber and nylon fiber. The monofilament diameter of the aramid fiber is 30 microns, and the fiber density in the crack arrest layer is 1.45g / cm2; the monofilament diameter of the nylon fiber is 20 microns, and the fiber density in the crack arrest layer is 1.26g / cm2.

[0095]The bullet-receiving layer is a high-hardness ceramic panel with a thickness of 7mm; the strength of the high-hardness ceramic panel is 3300MPa, and the toughness is 3J / square centimeter.

[0096] The basalt fiber / carbon fiber hybrid layer is a transition layer with a thickness of 2mm; in the basalt fiber composite material, the mixing ratio of basalt fiber and carbon fiber is 50% to 50%, the resin content is 30%, the tensile s...

experiment example 1

[0106] The test is carried out in the standard ballistic laboratory, the ammunition is kept at a constant temperature for 2 hours under standard temperature conditions, and the flight speed of the warhead is measured by the AVL Group B215 / B570 ballistic test system.

[0107] The detection gun used in the test is a Type 56 7.62mm submachine gun, and the detection bullet used in the test is a Type 56 7.62mm ordinary steel core bullet.

[0108] The test sample is the basalt composite bulletproof plate prepared in Example 1.

[0109] During the two inspections, the shooting distance is 15m, and the incident angle is 0°, that is, it is perpendicular to the target plate. The result is as follows:

[0110] After the first shot, the velocity of the warhead was detected to be 713m / s, and the bulletproof plate was not penetrated. The diameter of the bullet wound on the front was 47mm, the depth of the bullet wound was 14.5mm, the diameter of the bullet wound on the back of the bulletpr...

experiment example 2

[0114] The test is carried out in the standard ballistic laboratory, the ammunition is kept at a constant temperature for 2 hours under standard temperature conditions, and the flight speed of the warhead is measured by the AVL Group B215 / B470 ballistic test system.

[0115] The detection gun used in the test is a Type 95 5.8mm automatic rifle, and the detection bullet used in the test is a DSP87 type 5.8mm ordinary steel core bullet.

[0116] The test samples are the basalt composite bulletproof panels prepared in Example 1 and Comparative Example 1. During the detection process, the shooting distance is 15m, and the incident angle is 0°, that is, it is perpendicular to the target plate.

[0117] Embodiment 1 detection result is as follows:

[0118] After the first shot, the velocity of the warhead was detected to be 939m / s, and the bulletproof plate was not penetrated. The diameter of the bullet wound on the front was 27mm, the depth of the bullet wound was 40mm, the diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com