Large range nanometer grade step piezoelectric micromotion working platform, and its driving and controlling system

A technology of working platform and drive control, which is applied in the general control system, control/regulation system, electrical program control, etc., and can solve the problems of high price and difficult application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following drawings describe the present invention in detail.

[0024] Embodiments of the present invention's large-stroke nanoscale step-pitch piezoelectric micro-motion working platform:

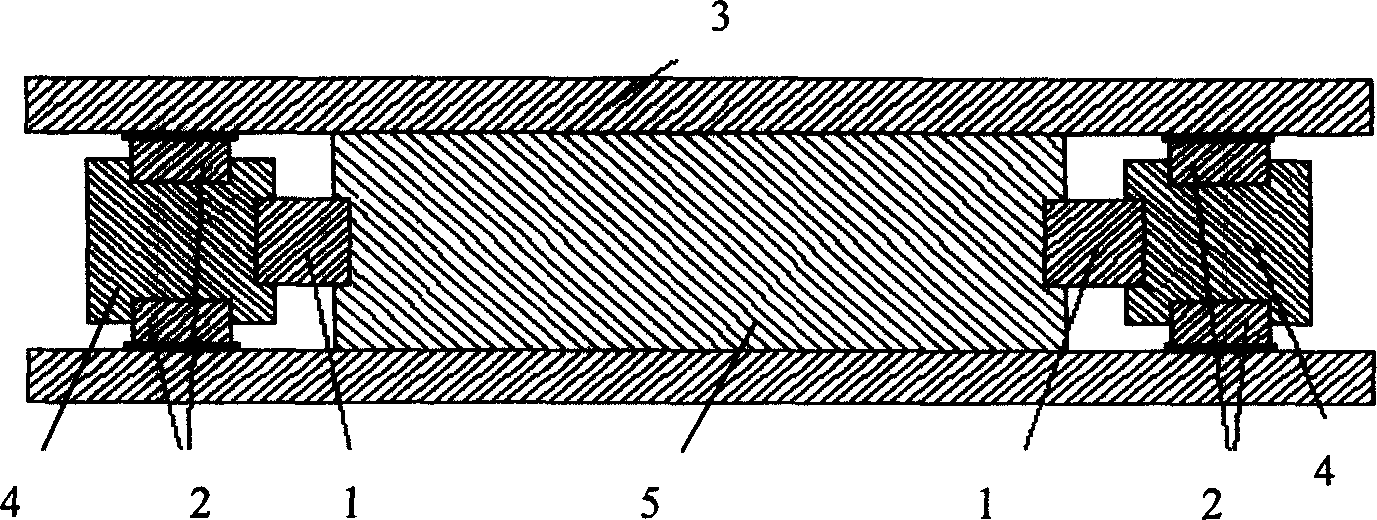

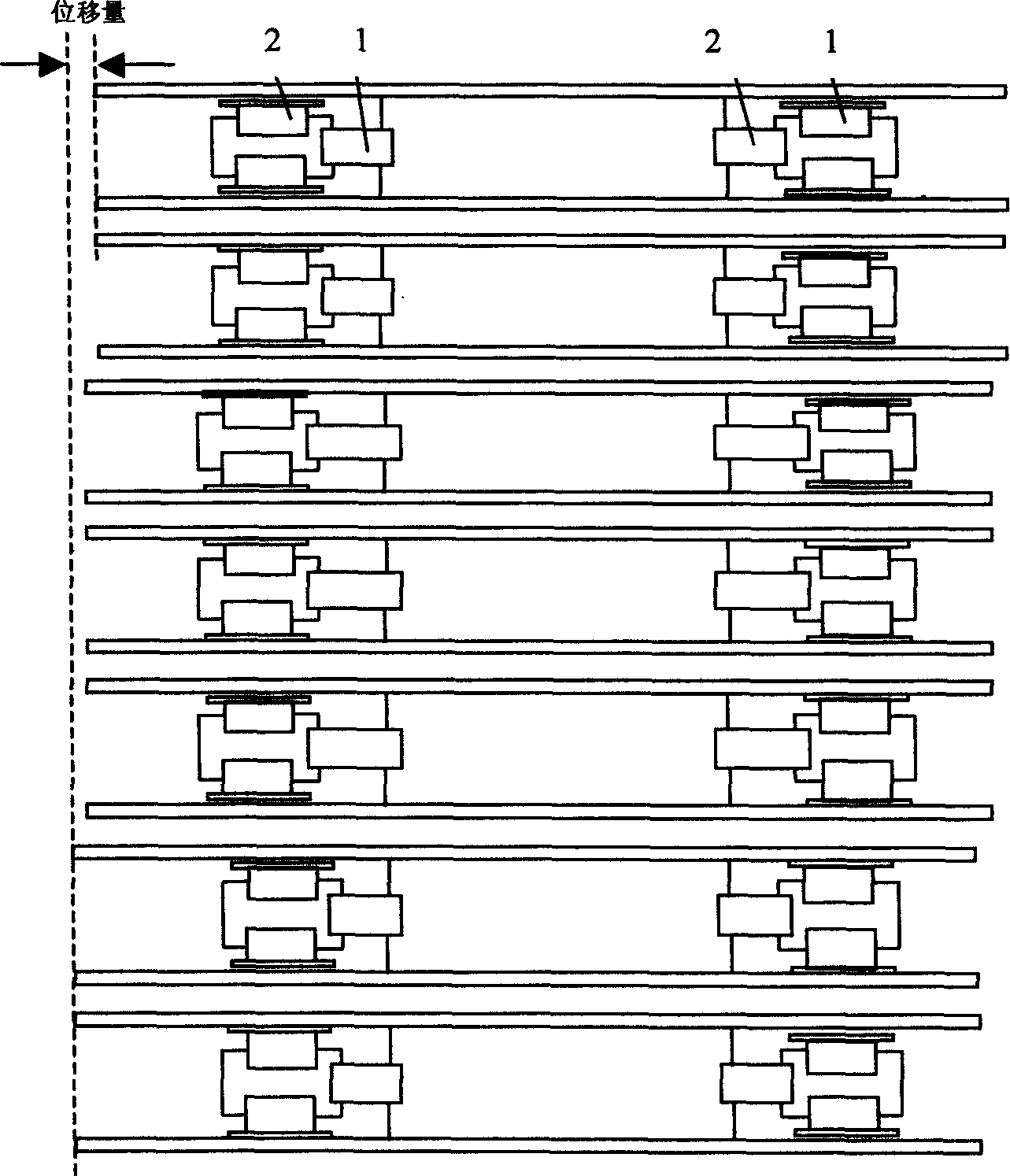

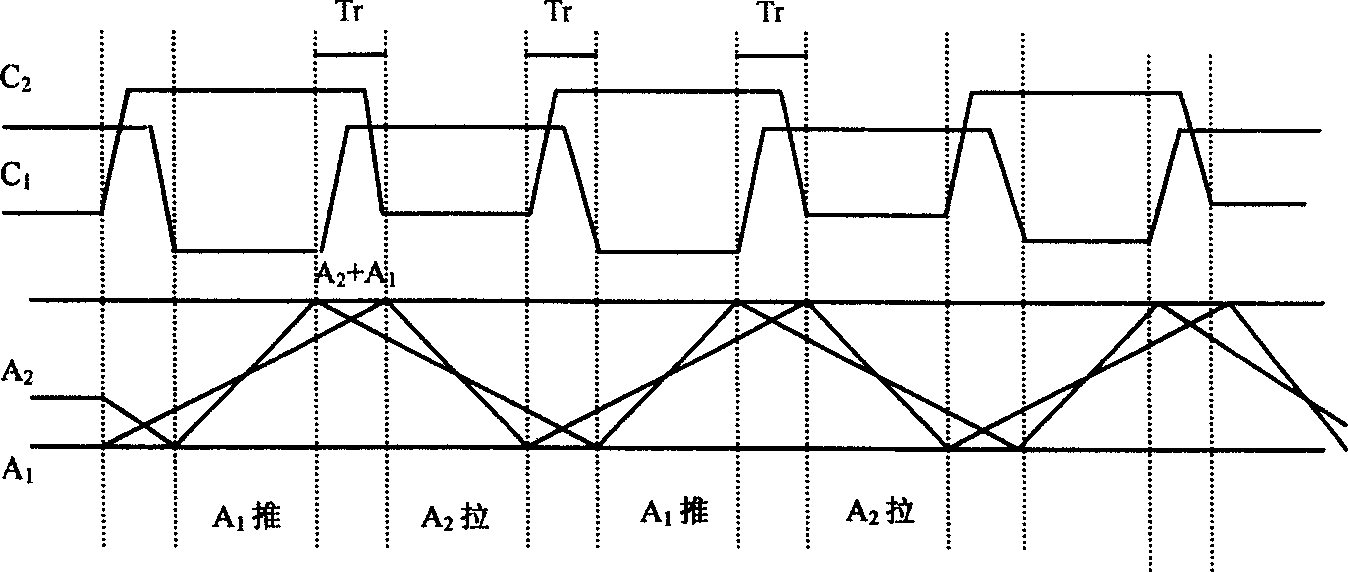

[0025] Such as figure 1 As shown, the piezoelectric micro-motion working platform of the present invention includes a platform 3 , a guide rail block 5 , a base, two clampers 2 , and two drivers 1 . Among the two clamps, the clamp on the left in the figure is C 1 , the clamp on the right in the figure is C 2 . Among the two drives, the drive on the left in the figure is A 1 , the drive on the right in the figure is A 2 . Consists of a clamper and a driver to form a unit. Because the principles, structures and functions of the two units are exactly the same, the two units are placed symmetrically, which not only increases the driving force of the micro-motion working platform, but also increases the stability of the operation, and the structure is simple. , easy to install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com