Fluorescent bulb retaining spring

一种支承弹簧、荧光灯的技术,应用在荧光灯领域,达到可靠减负的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

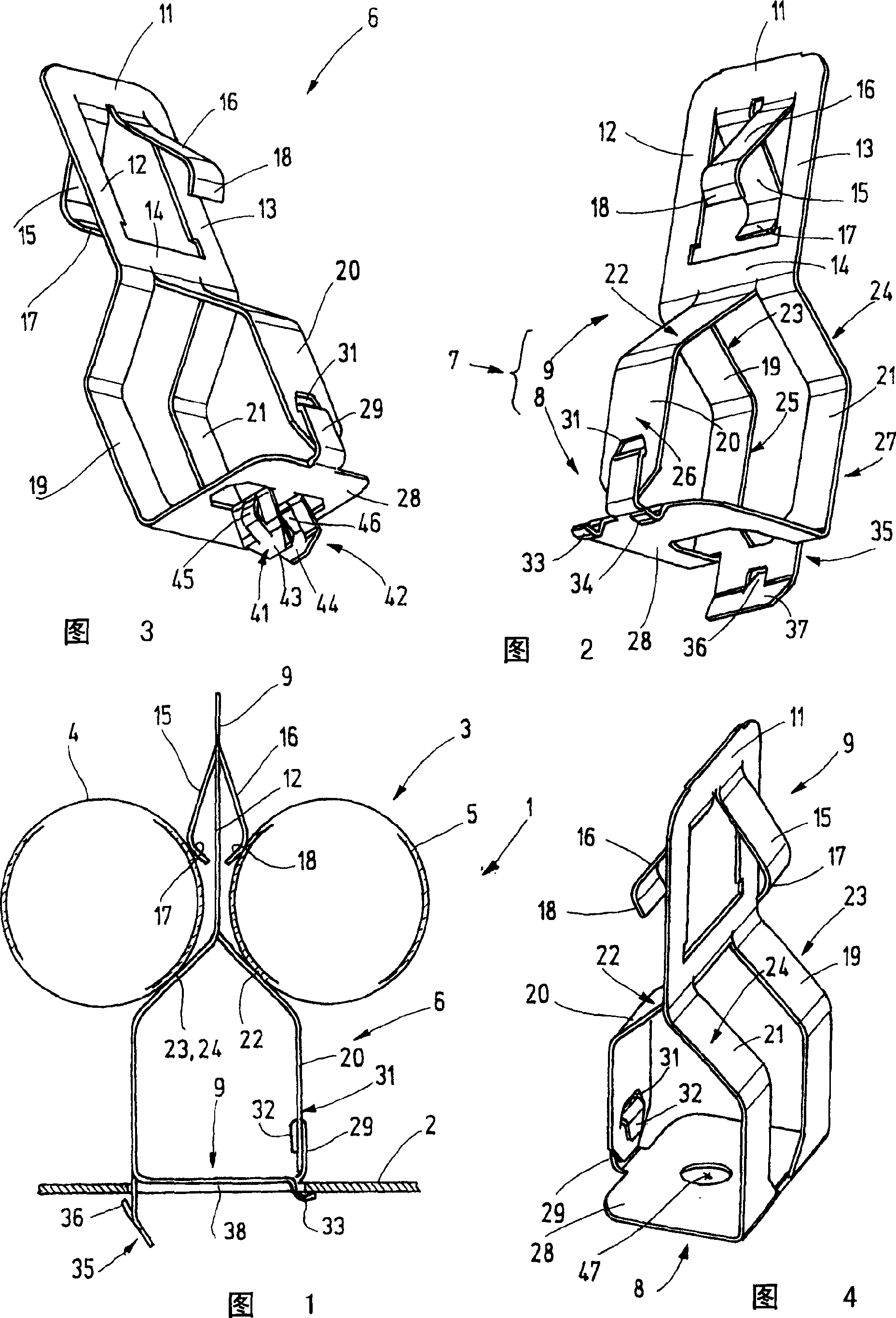

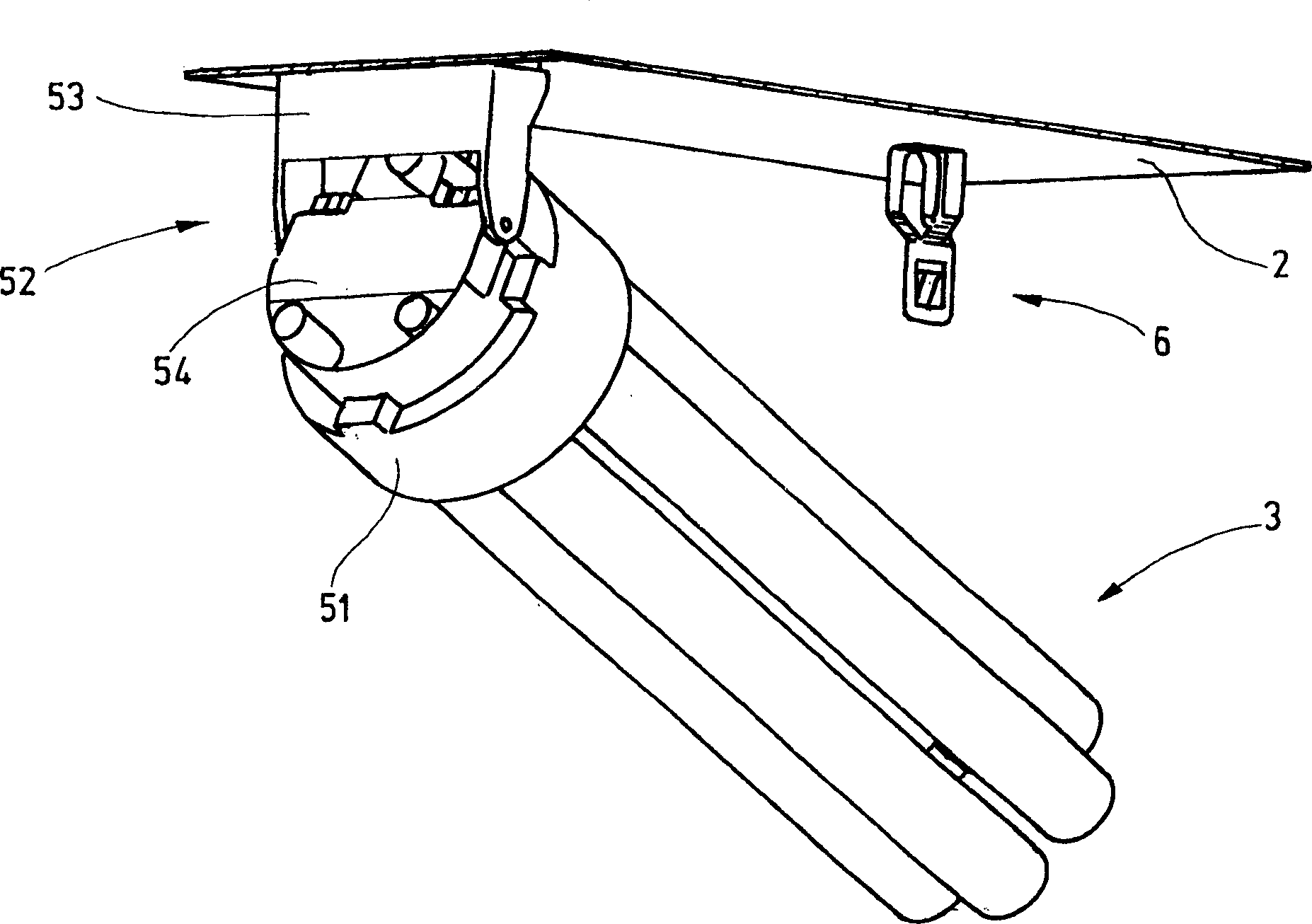

[0020] 1 shows a section through a luminaire 1 with a luminaire housing 2 and a fluorescent lamp 3 having a U-shaped discharge vessel whose branches 4 , 5 are arranged parallel to one another at a small distance. The discharge tube has a plug at one end. The plug and its socket are shown in FIG. 1 . In the case of a relatively large distance from the lamp cap, a support spring 6, which supports the free-floating end of the fluorescent lamp 3, is preferably provided approximately at the end of the discharge vessel, ie in the vicinity of the interconnected end of the branch tubes 4, 5. On the lamp housing 2. This not only applies to the horizontal installation of the fluorescent lamp 3 as shown in Figure 1, but also to the imaginary suspension installation when Figure 1 is turned upside down, or the horizontal installation with side lamp housing when Figure 1 is rotated 90°. . The support spring 6 can also be used for the vertically arranged fluorescent lamps 3 to fix the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com